Copper dissolving tank

A technology for dissolving copper tanks and cylinders, which is applied in the direction of copper sulfate, etc., can solve the problems of inconvenient maintenance, failure to filter, and many impurities in sulfuric acid solution, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

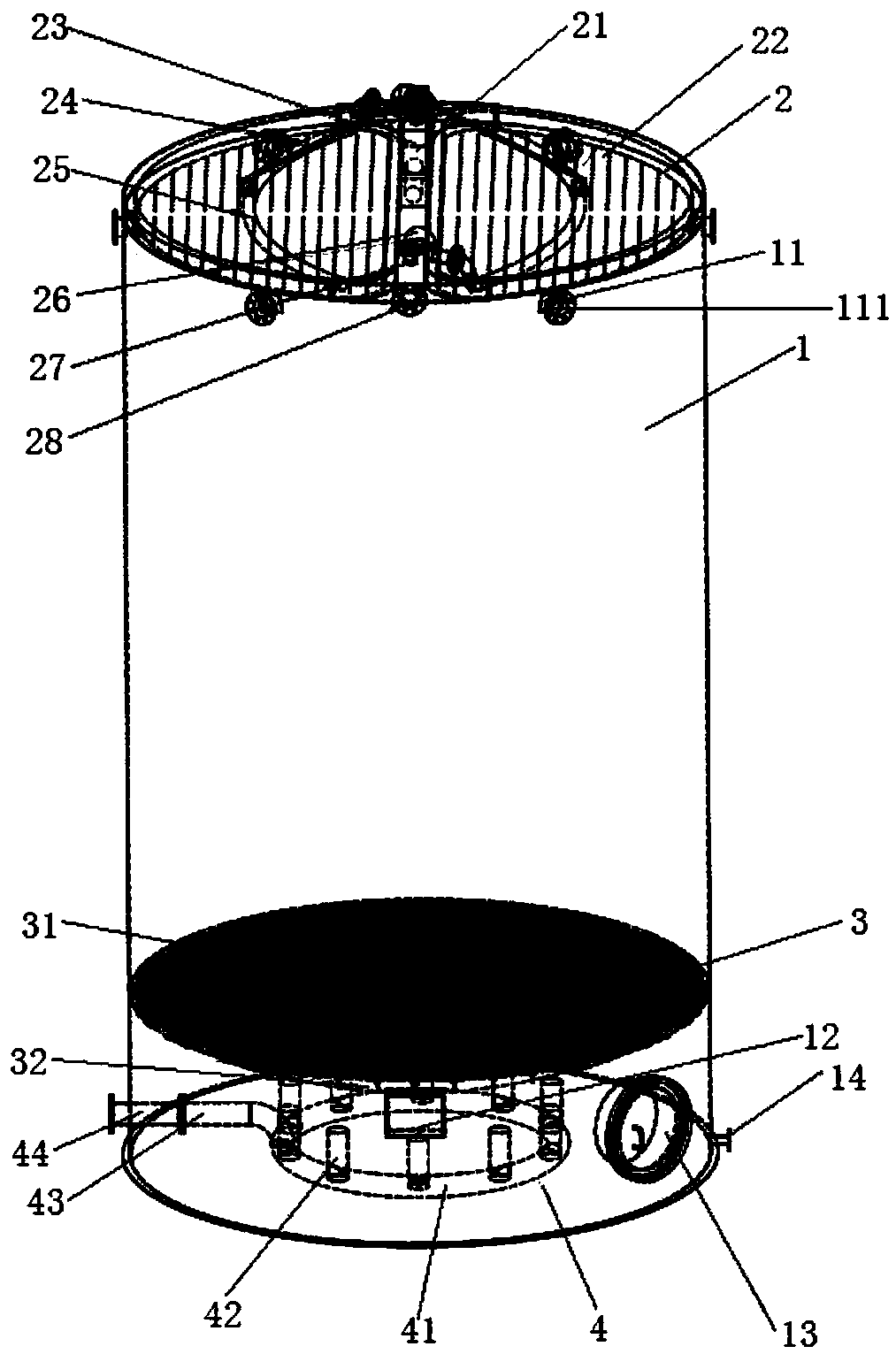

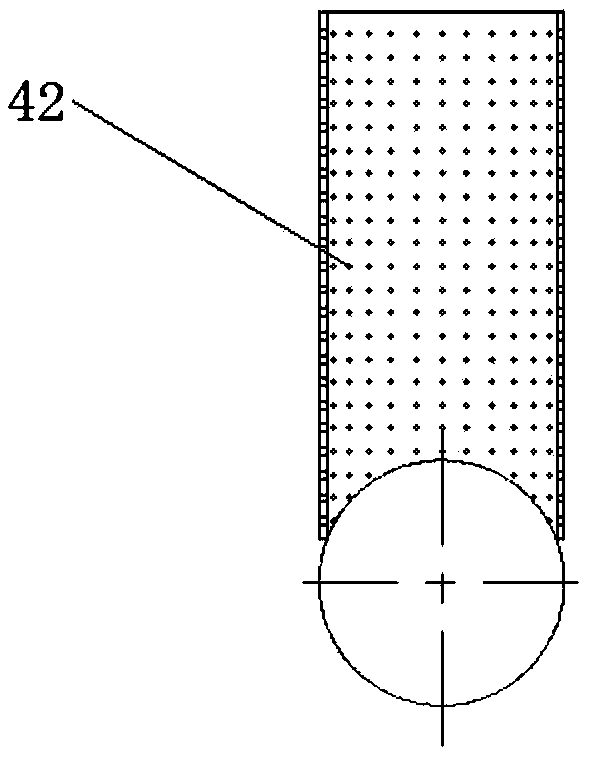

[0021] Such as Figure 1-Figure 4 As shown, the copper melting tank of the present invention includes a cylinder body 1, a spray top cover 2, a porous plate structure 3 and a liquid receiving tank coil 4, wherein:

[0022] The upper part of the cylinder 1 is evenly provided with six air inlets 11 along the circumferential direction, and the windshield 111 is arranged inside the air outlet 11, and two square air inlets 12 are arranged on the side of the lower part of the cylinder 1, and the two air inlets 12 The front and back are symmetrically arranged, the lower end of the cylinder 1 is provided with a manhole 13, and the side of the cylinder 1 near the bottom is provided with a drain port 14.

[0023] The spray top cover 2 is set on the mouth position of the upper end of the cylinder body 1. The spray top cover 2 is a double-layer cover structure. The spray top cover 2 includes a middle fixed cavity 21 and two The movable cavity 22 on the side, the inner and lower cover of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com