Test tube drying device and method for student test

A technology for testing and test tubes, applied in drying, drying machines, drying solid materials, etc., can solve the problems of high frequency of use, more test tubes, and a large number of users at a time, achieving fast drying speed and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

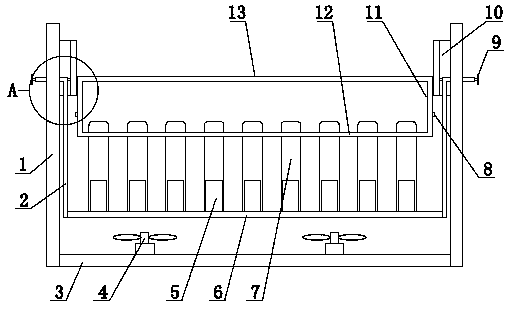

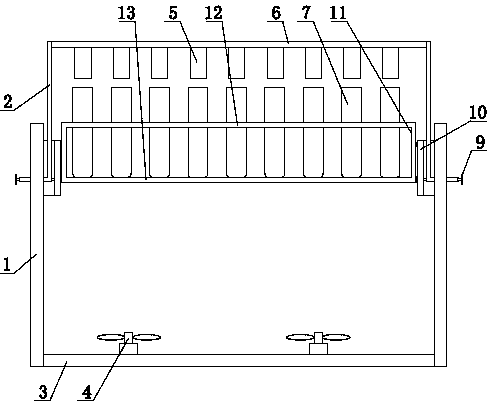

[0015] As shown in Fig. 1, Fig. 2 and Fig. 3, the test tube drying device for students' experiments includes a support base and a drying rack and a collecting rack arranged on the support base. The first test tube support structure on the collection rack has a plurality of second test tube support structures capable of inserting test tubes.

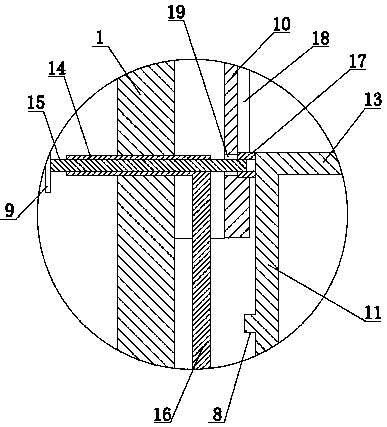

[0016] As shown in Figure 1, Figure 2 and Figure 3, the bracket seat is a U-shaped frame connected by two vertical plates 1 and a bottom plate 3, a fan 4 is installed on the bottom plate 3, and the drying rack includes a support plate 6 and two L Shaped swivel arm 2, support plate 6 adopts net plate, can ventilate. One end of the rotating arm 2 is a rotating shaft 14, and the other end is a connecting arm 16. The rotating shaft 14 is a hollow shaft. A connecting rod 15 that can slide axially is arranged in the rotating shaft 14. The connecting rod 15 is a non-rotating body, and the cross section can be square. , hexagonal, star-shaped an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com