Patents

Literature

35results about How to "Fast forwarding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

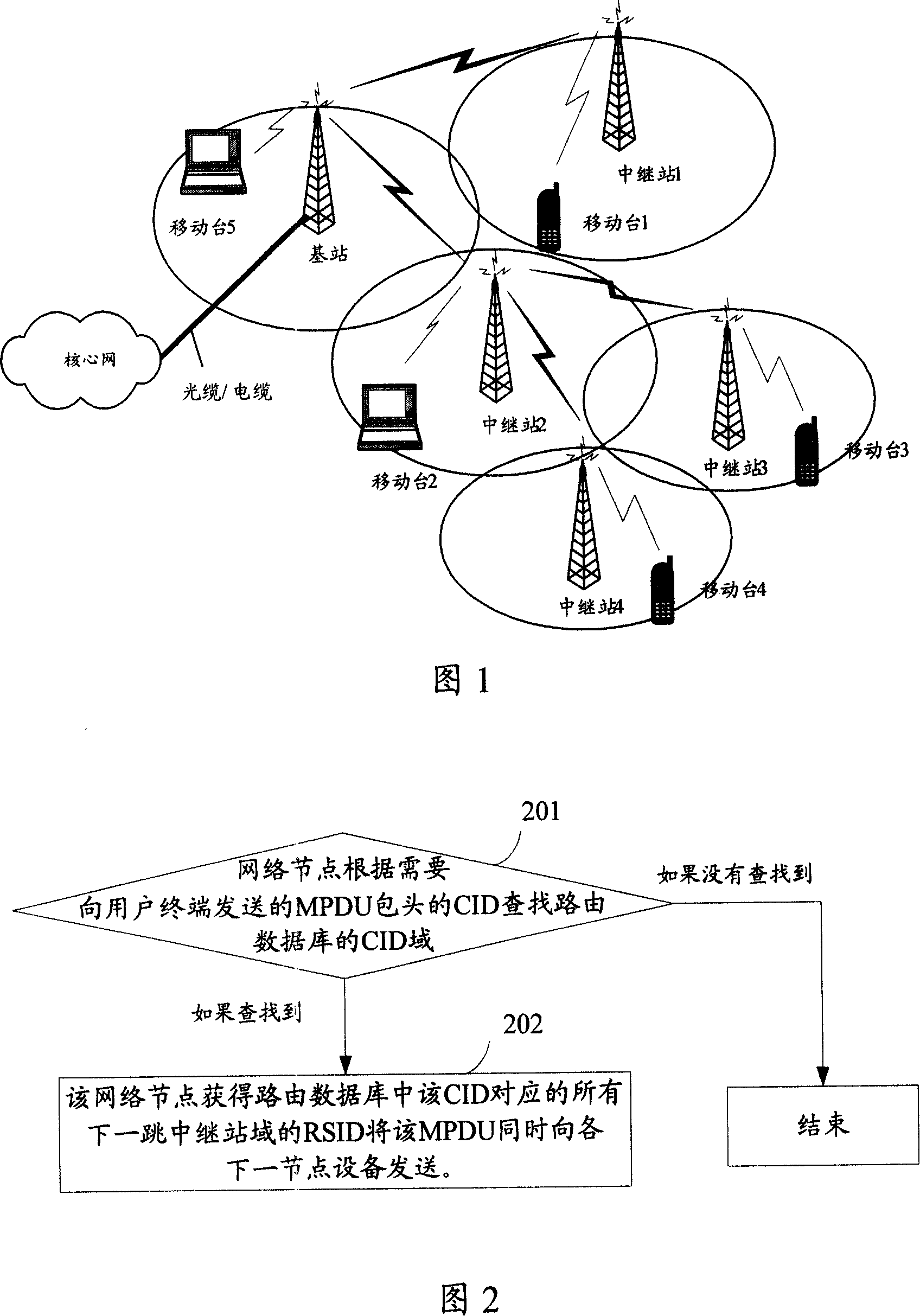

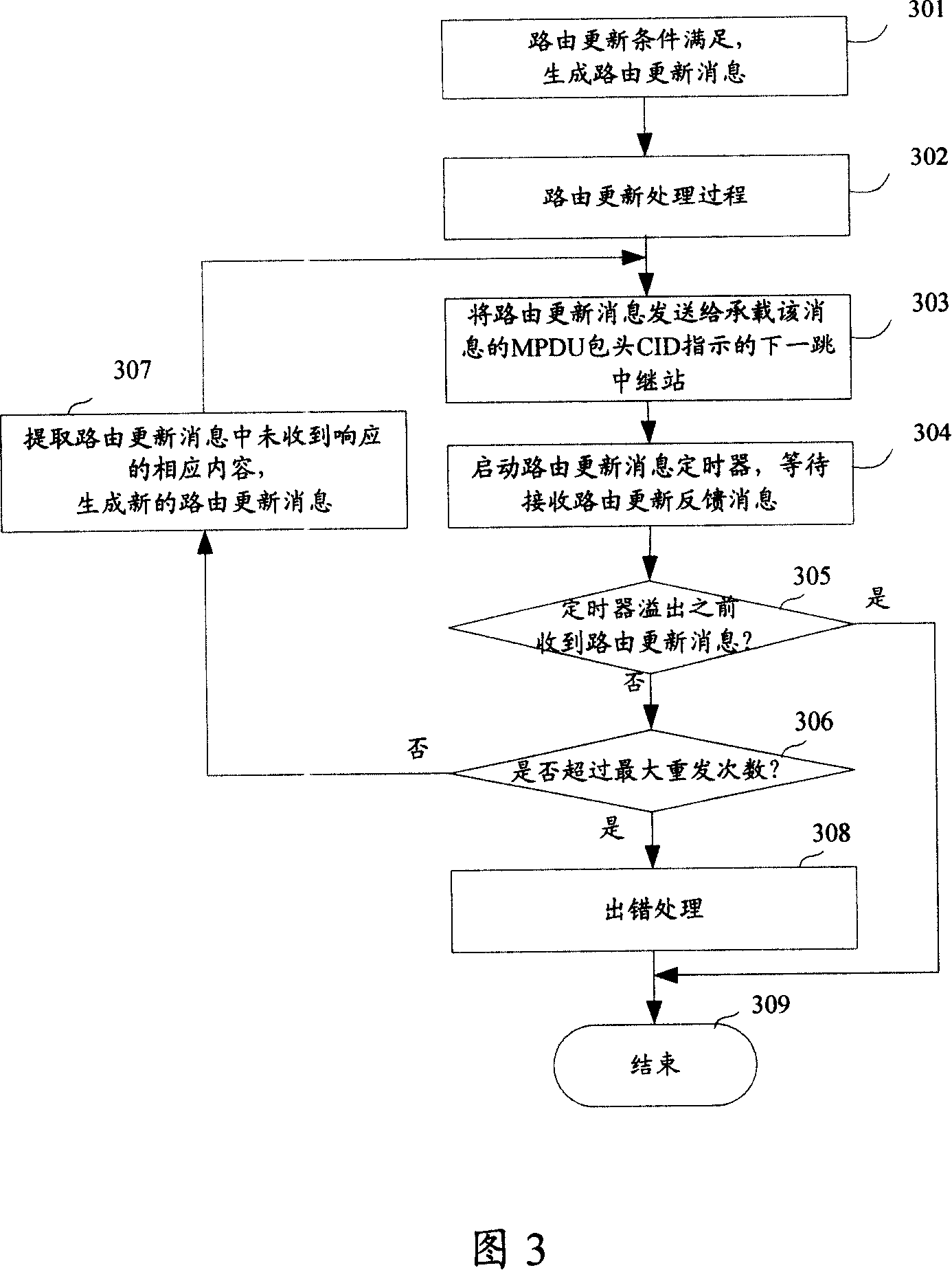

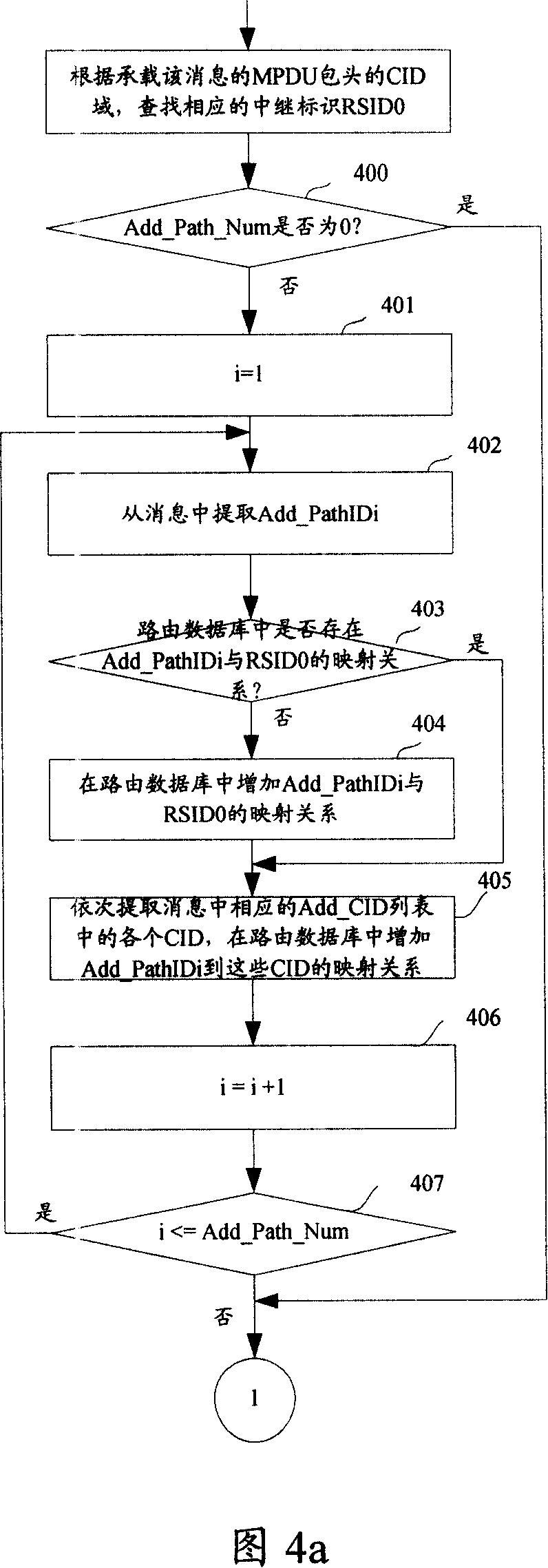

Multi-jumper radio relay communication system and its download data transmission method

ActiveCN101150498ANo need to change protocol structureReduce overheadData switching by path configurationNetwork data managementData transmissionMedia access control

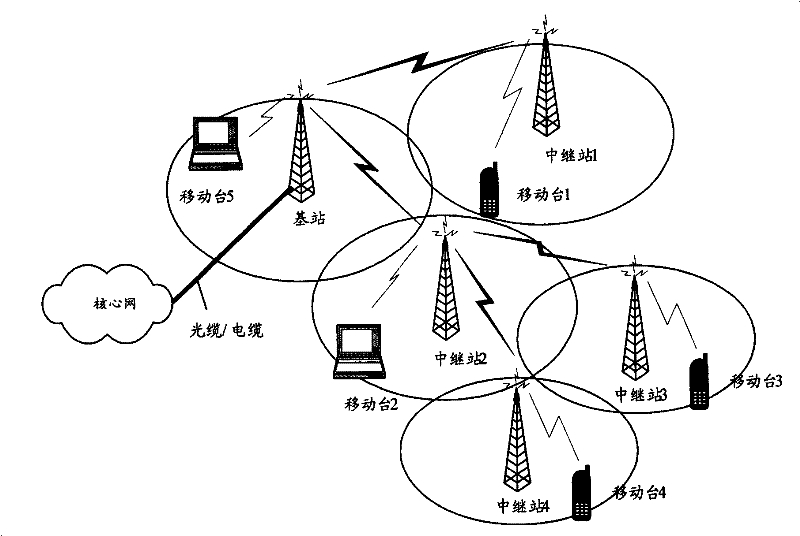

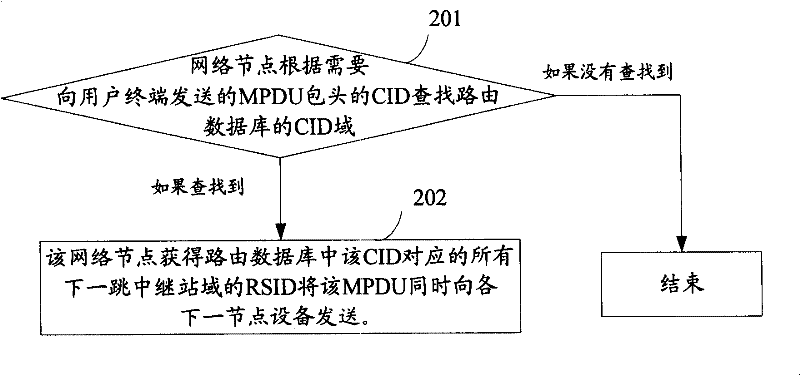

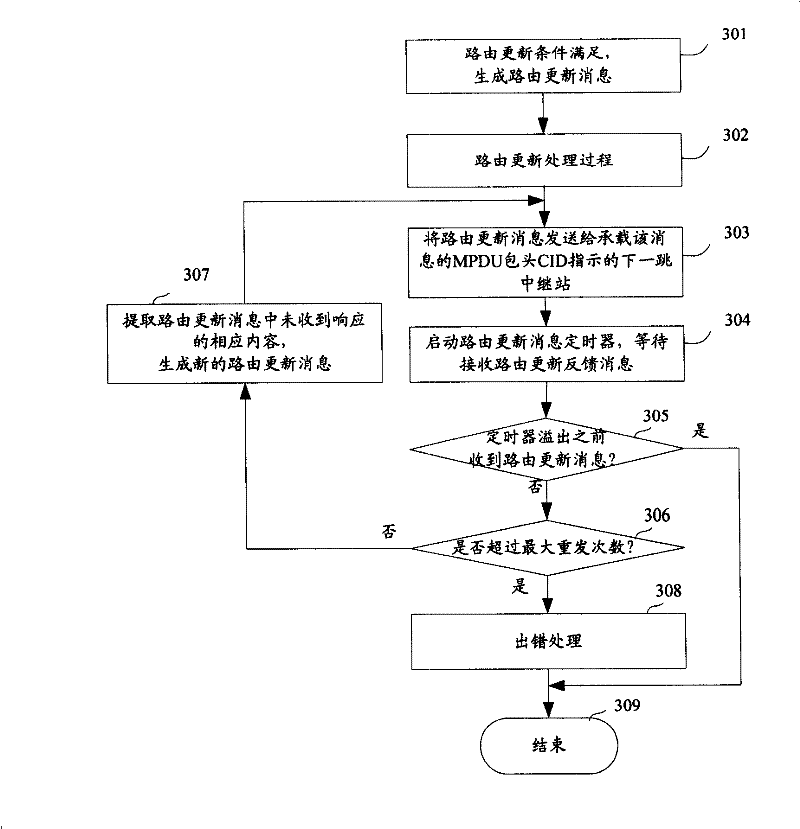

The invention discloses a method for transmitting downlink data, which is applied in multi-hop wireless relay communications system. The method includes the following steps: a base station and each relay station are respectively provided with a route database stored with a corresponding relationship which includes the connection mark of a consumer terminal and a mark of a relay station in the next hop; in the route database, a node device searches a connection mark of the packet head of a downlink Media Access Control Protocol Data Unit (MPDU); in case that the route database has the connection mark, the node device obtains the mark of all the relay stations in the next hop corresponding to the connection mark according to the corresponding relationship; then transmits the downlink Media Access Control Protocol Data Unit (MPDU) to all the relay stations in the next hop and to the user terminal finally. The invention realizes data transmission of multi-hop wireless communications system without changing the protocol structure of existing UE and core network. Furthermore, the invention also discloses a multi-hop wireless relay communications system as well as a base station and a relay station applied in the system.

Owner:HUAWEI TECH CO LTD

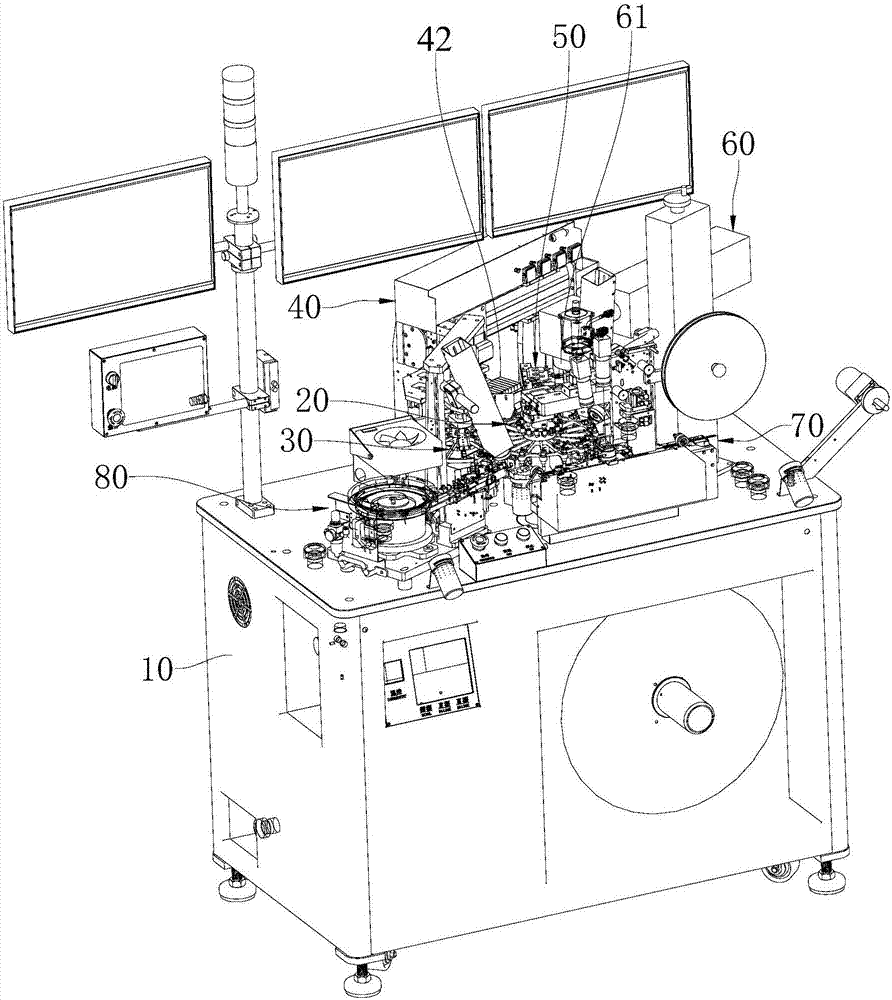

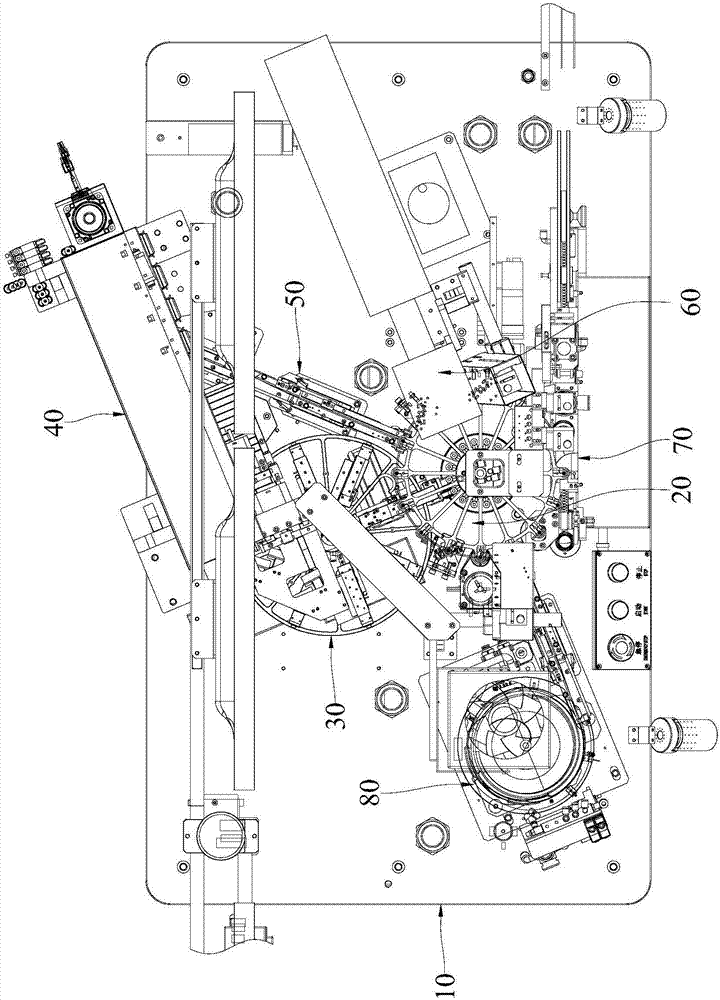

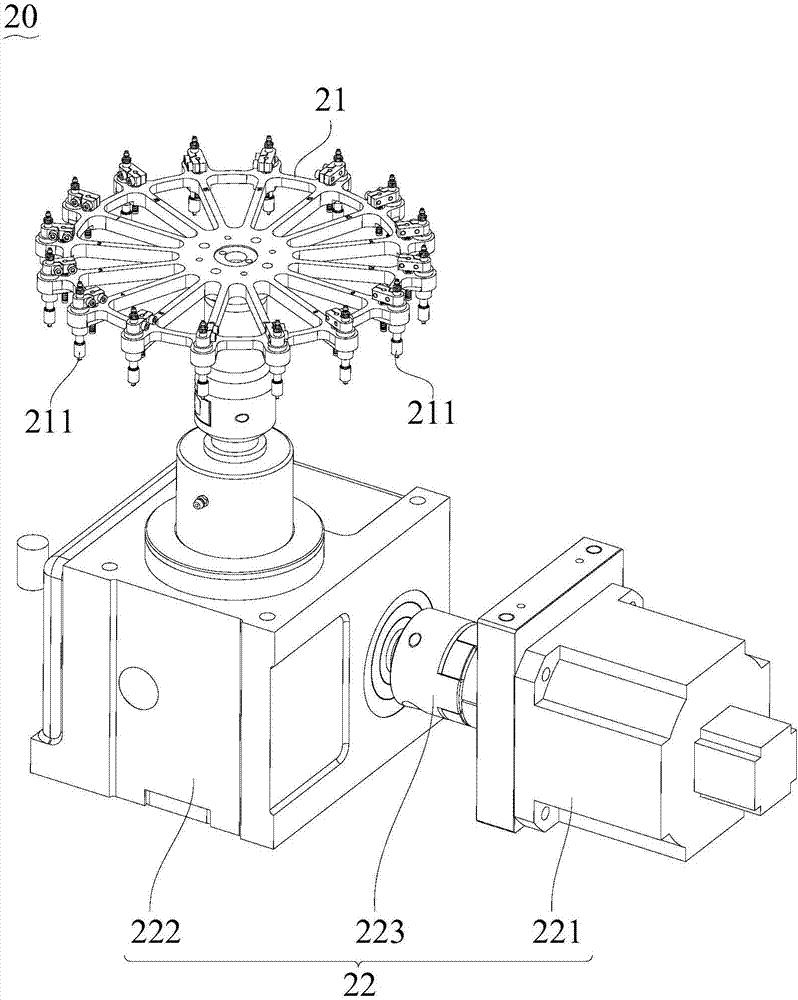

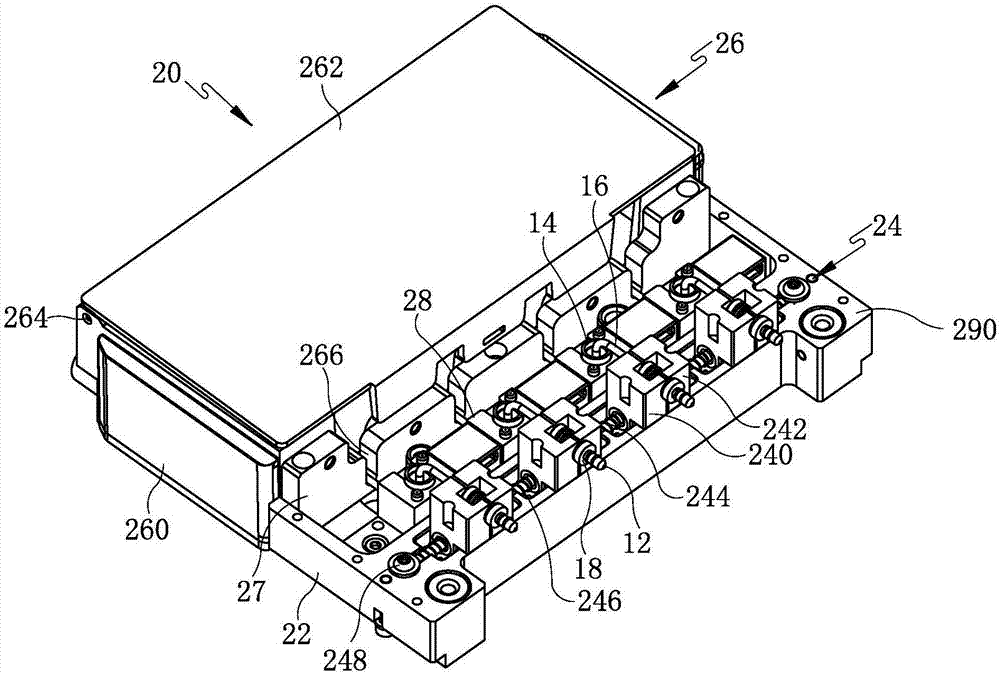

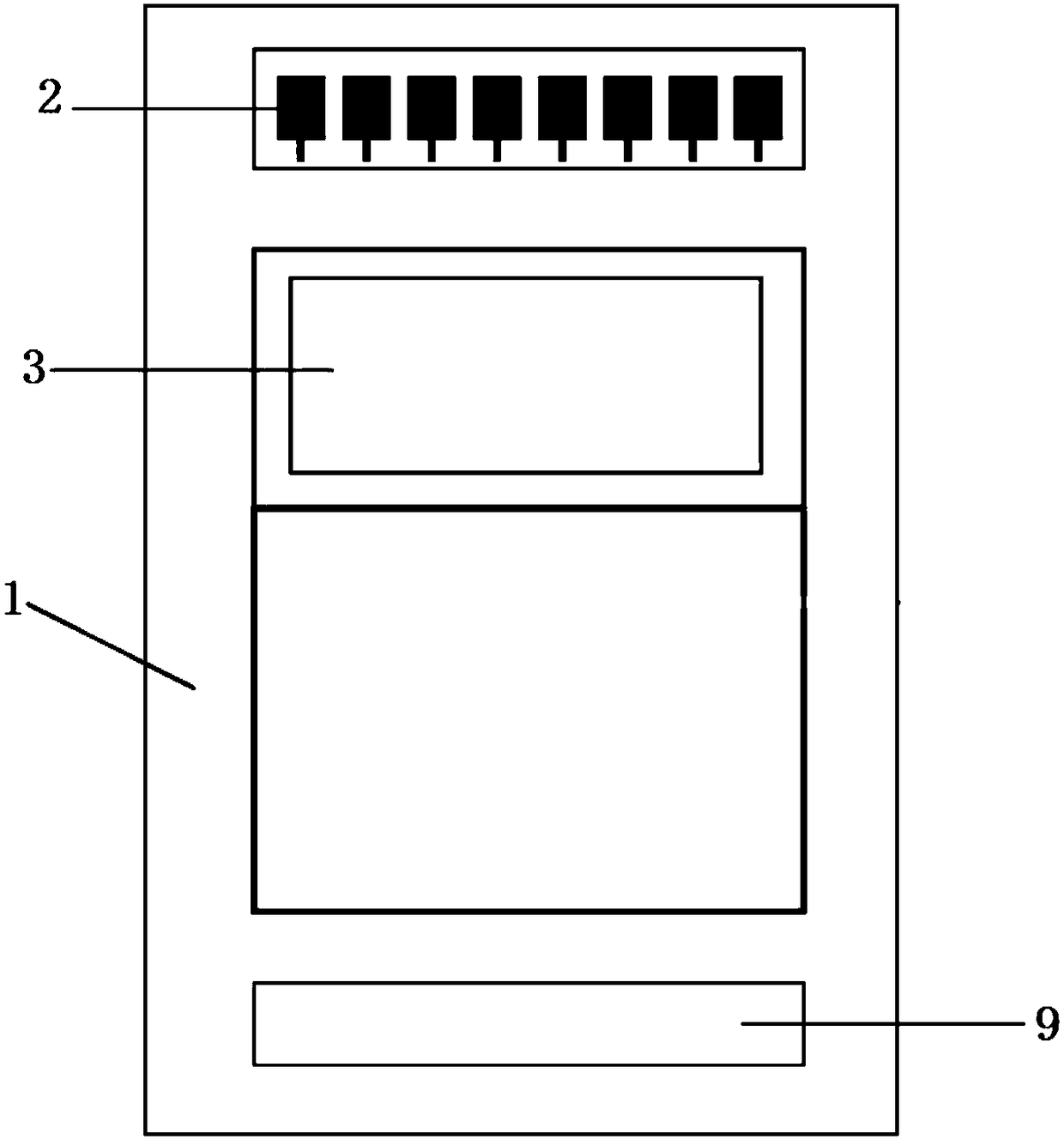

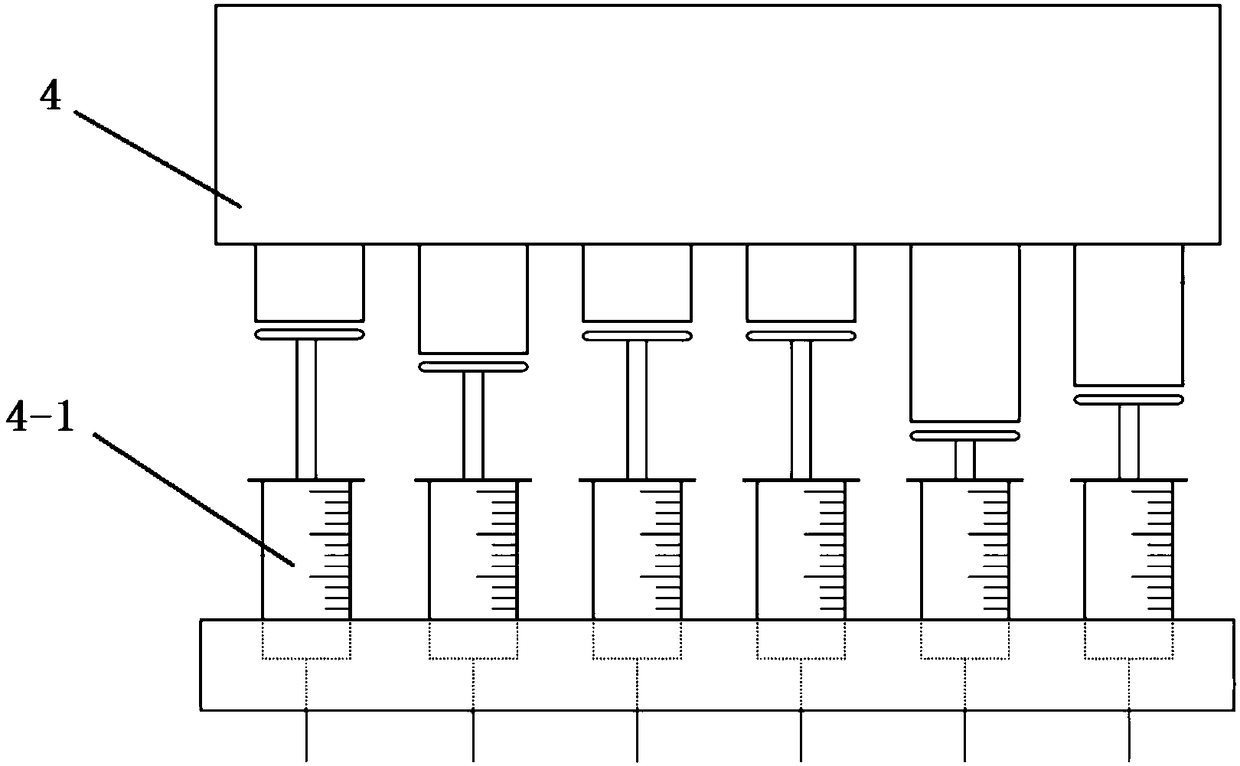

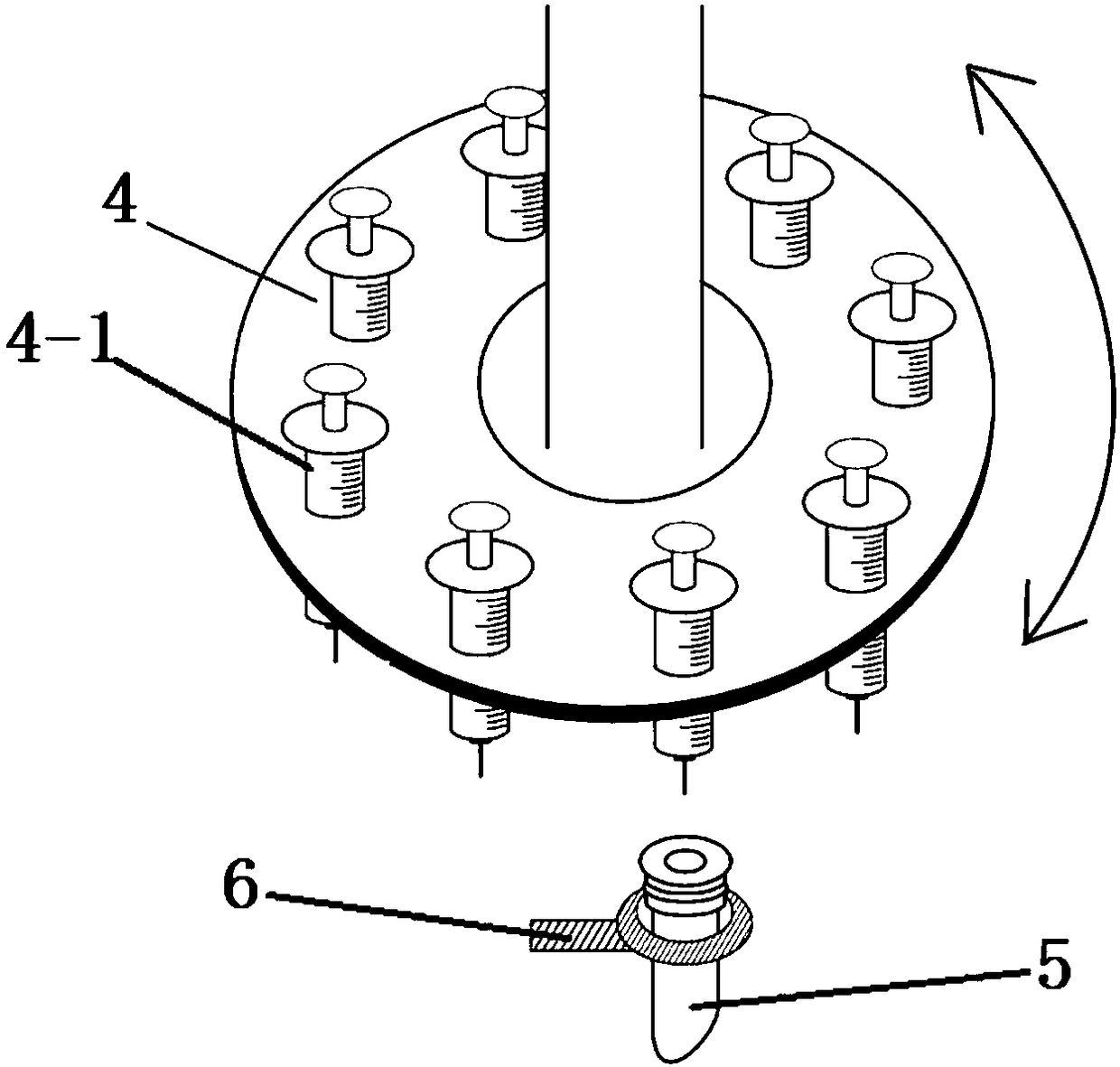

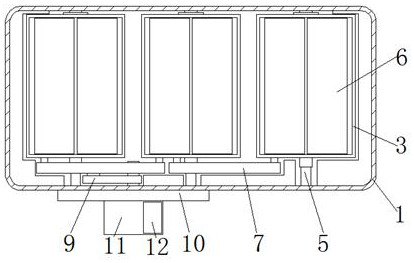

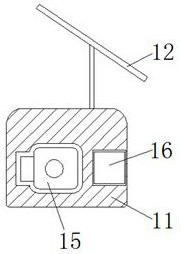

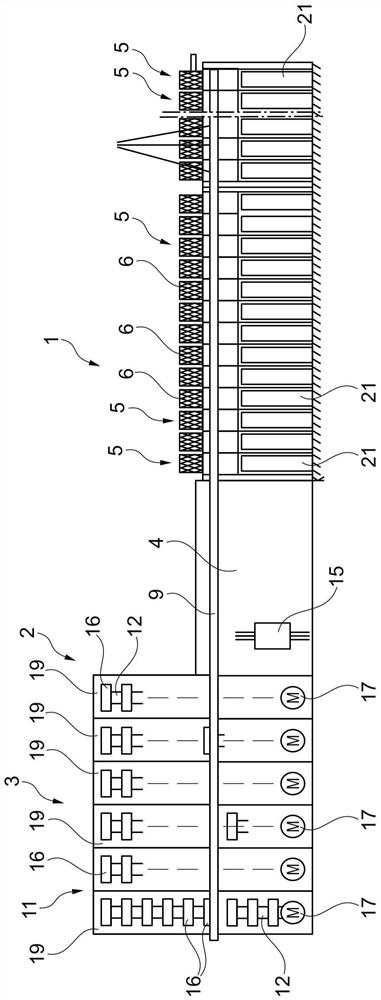

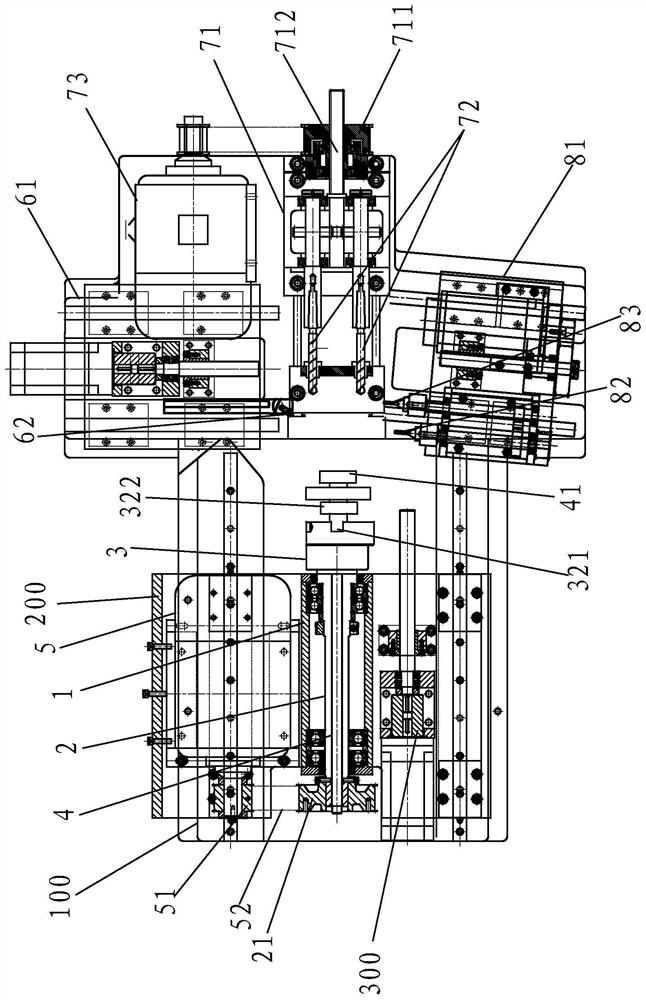

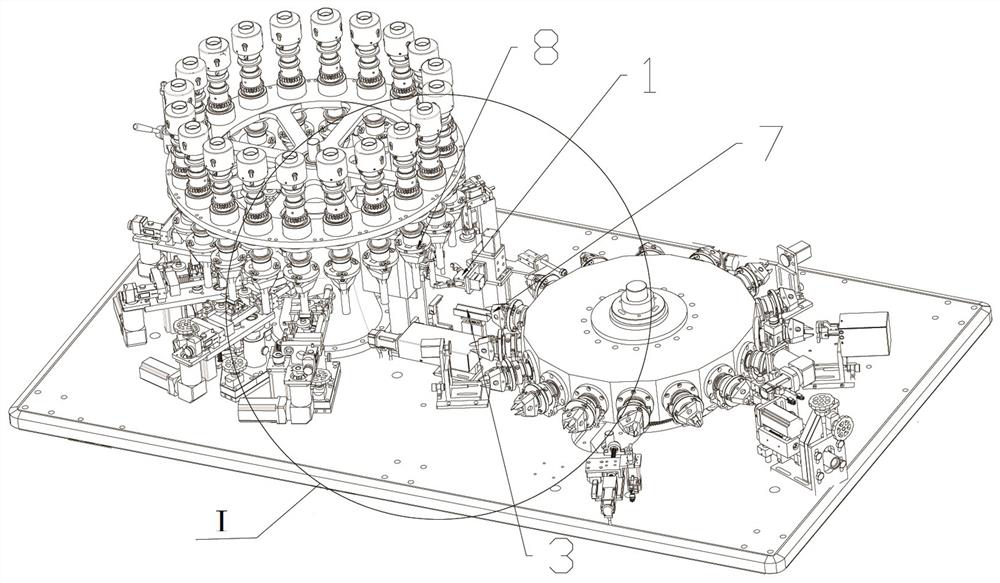

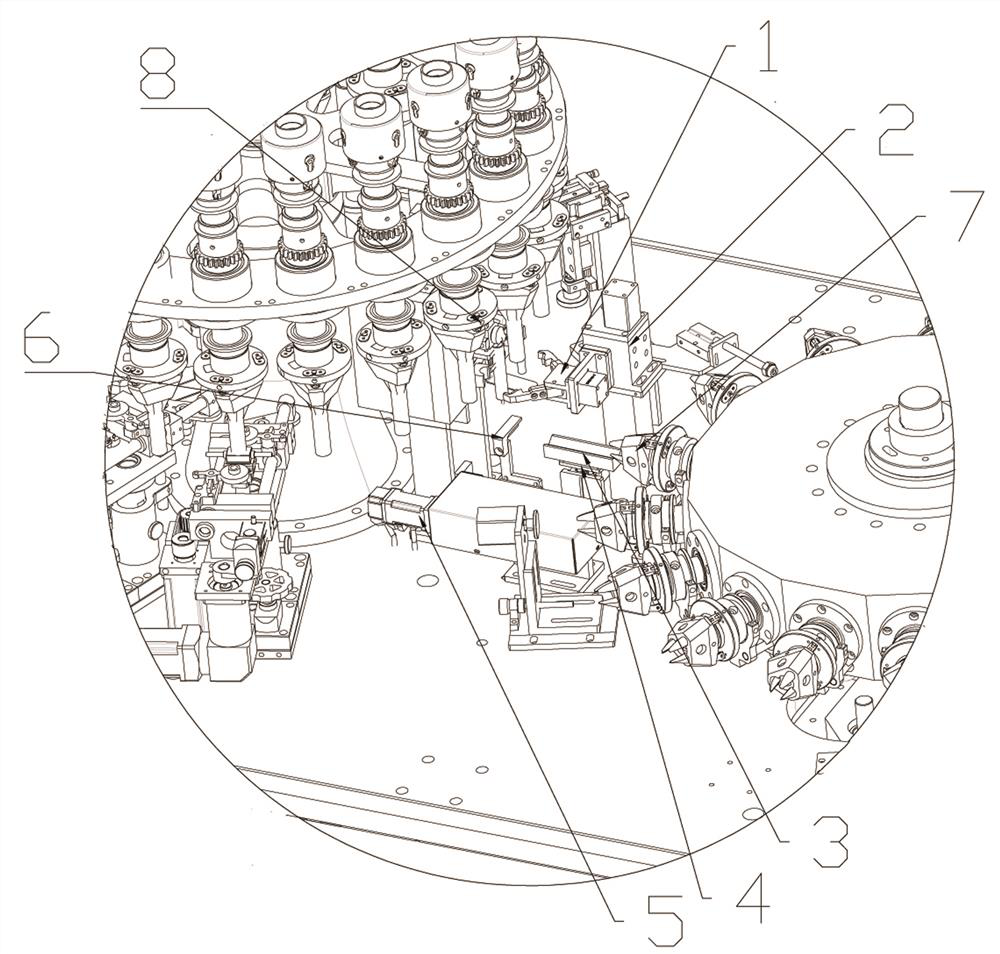

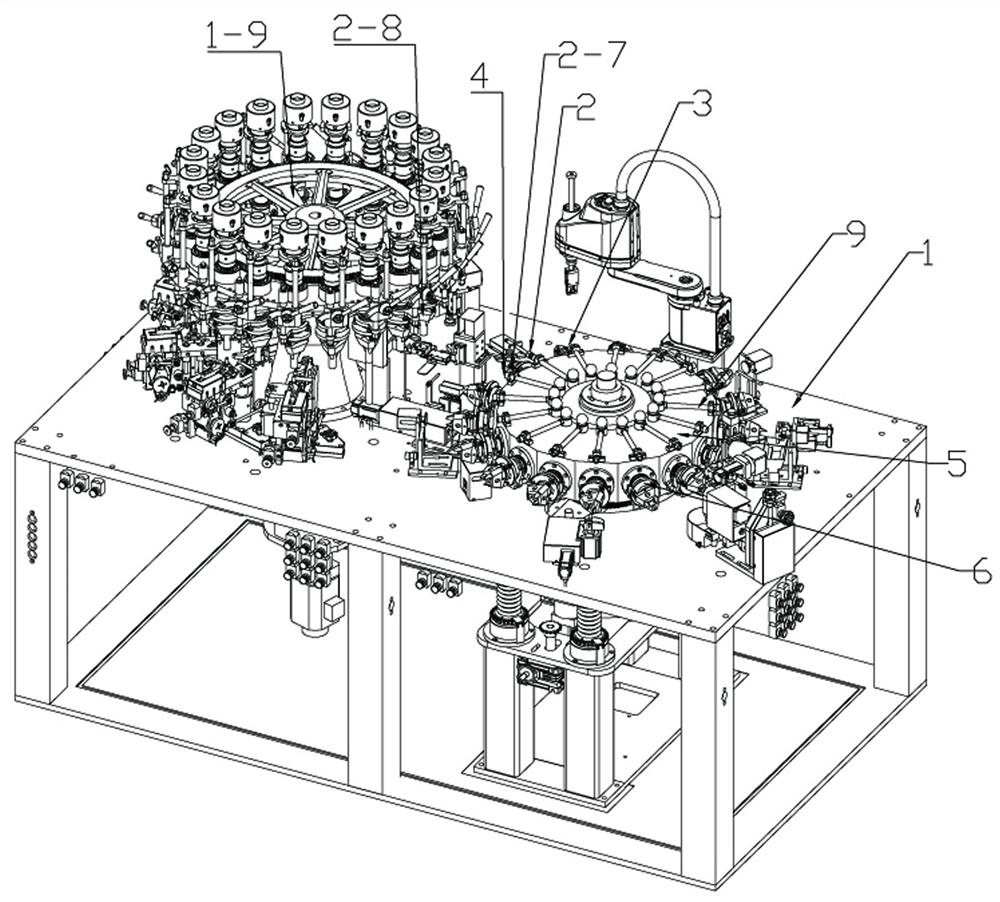

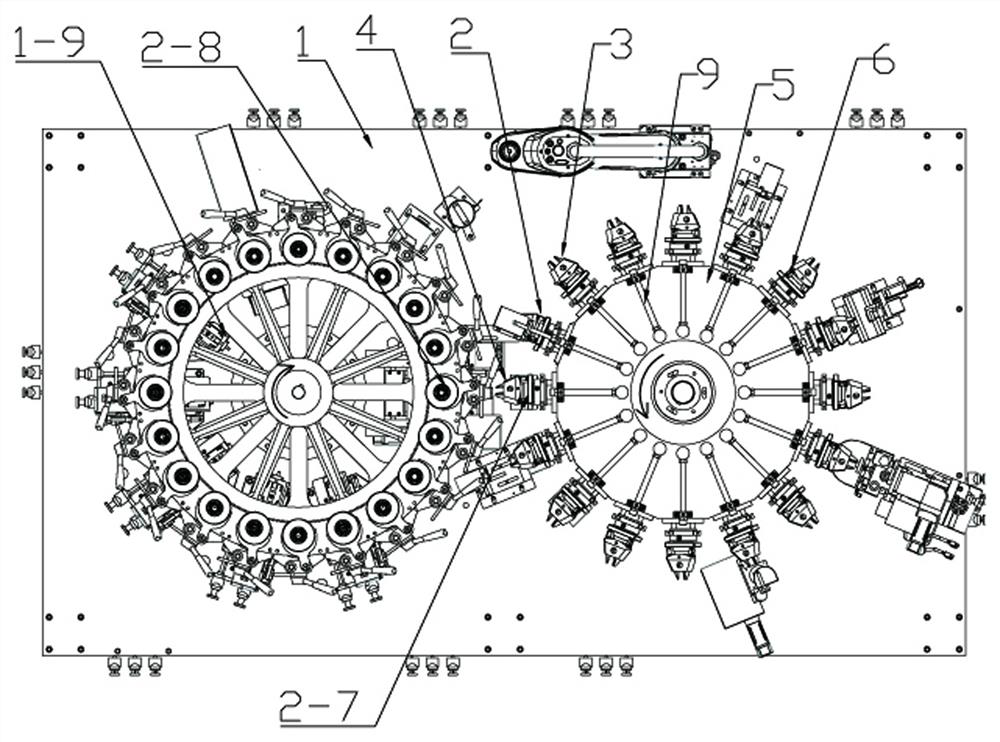

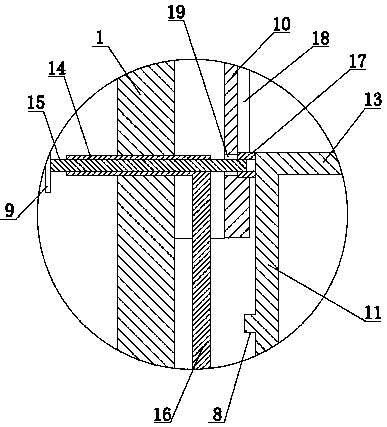

Multi-station crystal oscillator testing, classifying, marking and braiding integrated device

The invention belongs to the technical field of crystal oscillator processing equipment, and particularly relates to a multi-station crystal oscillator testing, classifying, marking and braiding integrated device. The multi-station crystal oscillator testing, classifying, marking and braiding integrated device comprises a box body, a feeding mechanism, a main rotating disk mechanism, an auxiliary rotating disk mechanism, a material picking and classifying mechanism, a material overturning mechanism, a material marking mechanism and a material braiding and packaging mechanism, wherein the feeding mechanism, the main rotating disk mechanism, the auxiliary rotating disk mechanism, the material picking and classifying mechanism, the material overturning mechanism, the material marking mechanism and the material braiding and packaging mechanism are arranged on the box body; the main rotating disk mechanism comprises a main rotating disk and a main driving source; the auxiliary rotating disk mechanism comprises an auxiliary rotating disk and an auxiliary driving source; the material picking and classifying mechanism comprises a fixing frame, a classifying material box, a testing driving device and an adsorbing driving device; the material overturning mechanism is arranged between the main rotating disk and the fixing frame; the material marking mechanism is arranged on one side of the main rotating disk; and the material braiding and packaging mechanism is arranged on one side of the material marking mechanism. Due to the design, integrated operation of testing, classifying, marking and braiding on crystal oscillators is achieved; and due to the multi-station processing design, the production efficiency of the crystal oscillators is greatly improved.

Owner:深圳市三一联光智能设备股份有限公司

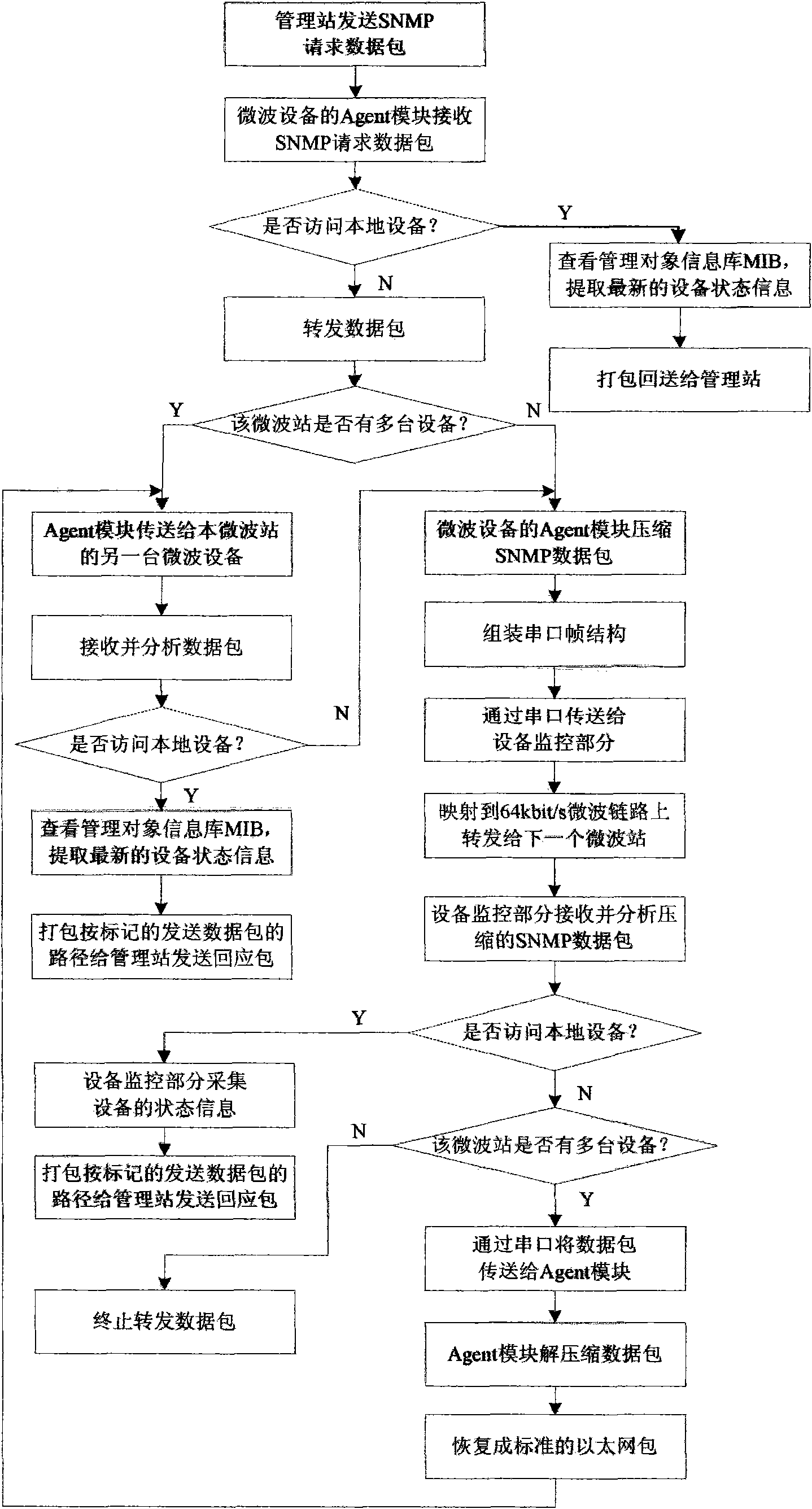

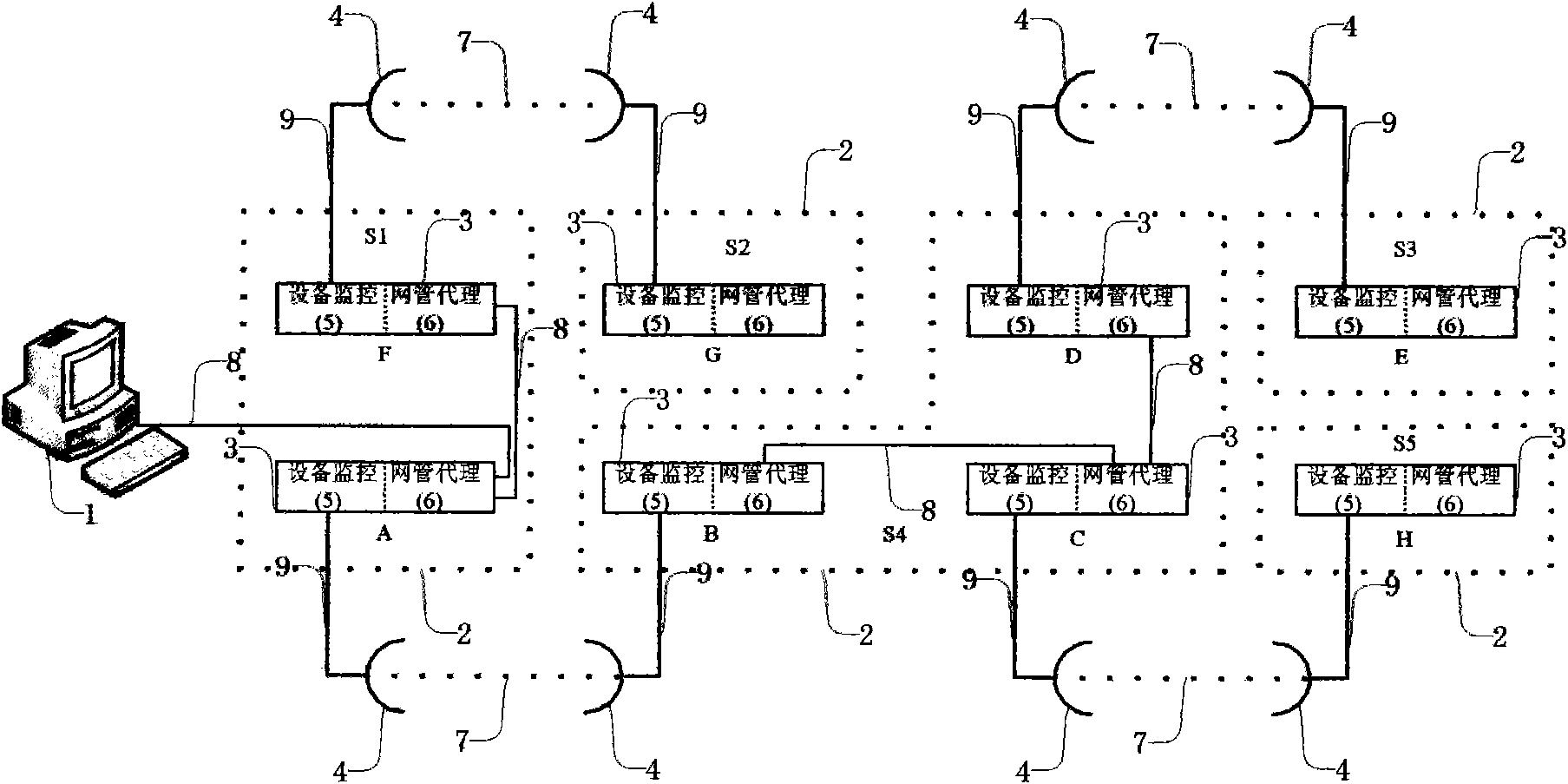

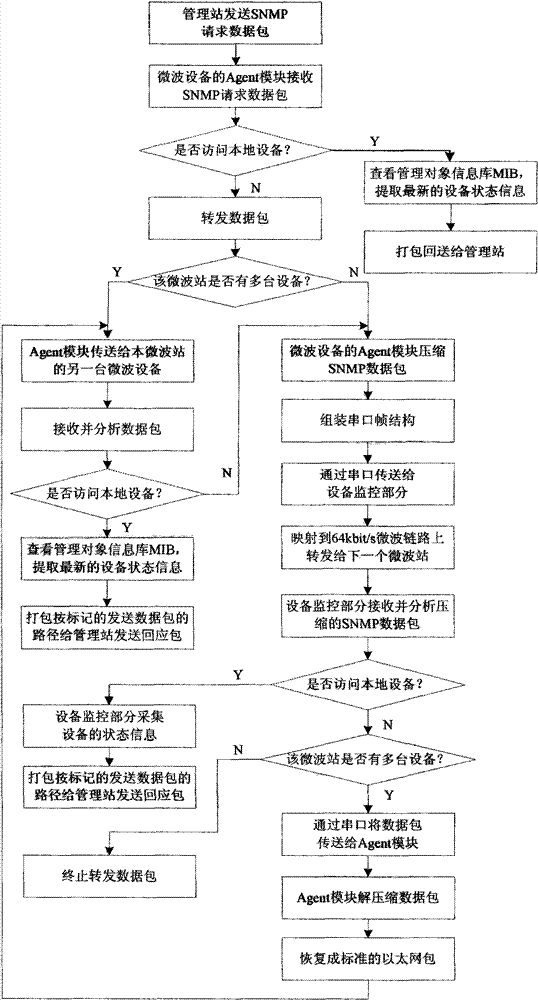

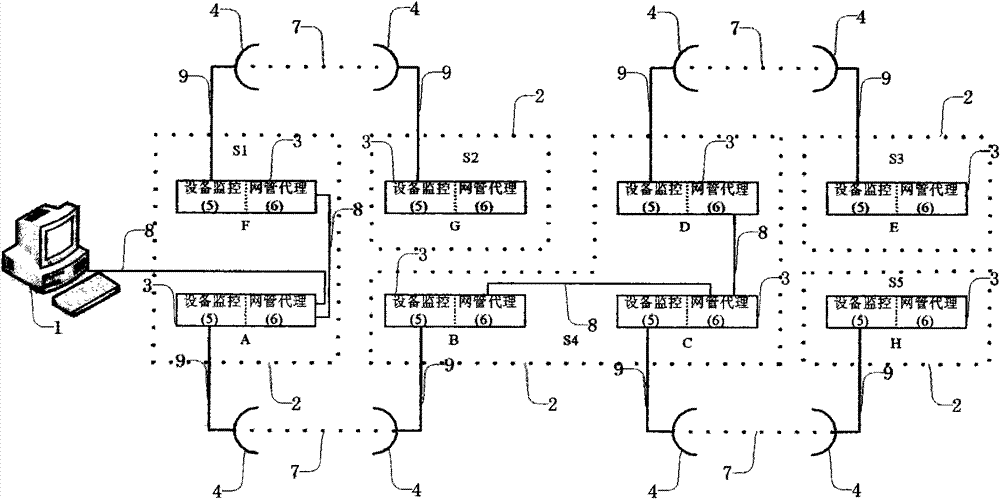

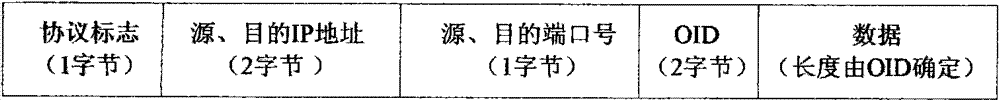

Ethernet network packet fast-forwarding realization method based on microwave facility network management system

InactiveCN101867493AAchieve remote accessTo achieve the purpose of controlData switching by path configurationSerial lineMicrowave

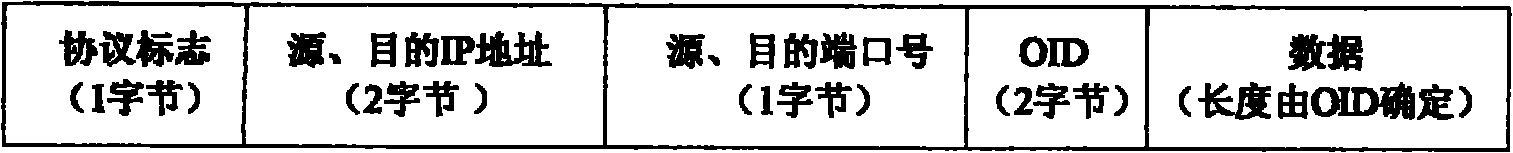

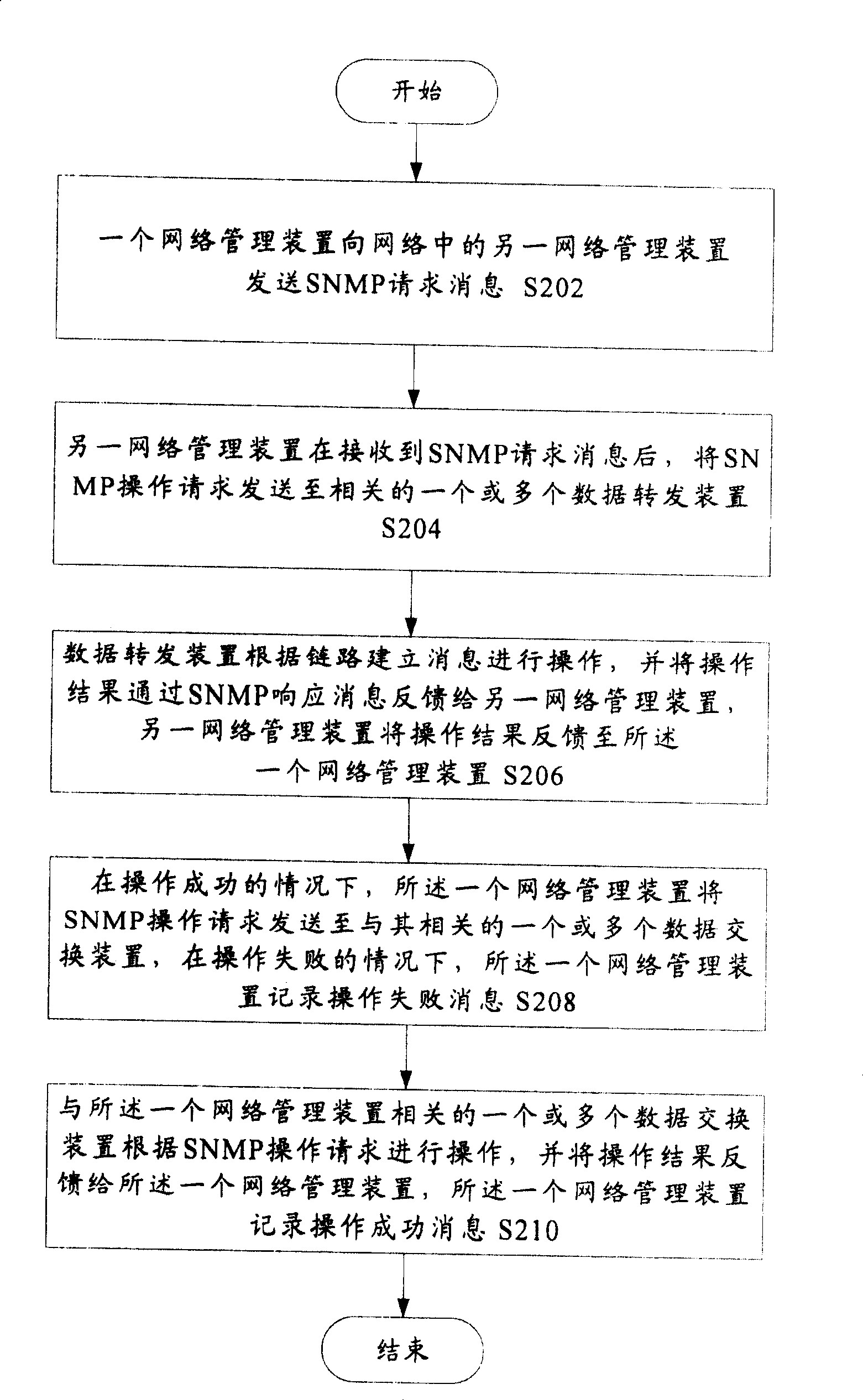

The invention relates to an ethernet network packet fast-forwarding realization method based on a microwave facility network management system; the method is realized based on the microwave facility network management system; the system comprises a management station and a plurality of microwave stations, the microwave station is composed of a microwave facility or a plurality of microwave facilities, the management station is connected with one microwave facility in one microwave station by a network line, a plurality of microwave facilities in one microwave station are connected by the network line, the adjacent microwave stations are connected mutually by a microwave link, self-definition is carried out to data format on the basis of simple network management protocol SNMP. In the invention, fast forwarding from the ethernet network packet structure to 64kbit / s serial line is realized, fast, stable and reliable forwarding requirements of a data packet are met, and the invention is a fast-forwarding realization method of the ethernet network packet in the serial link.

Owner:XIAN UNIV OF POSTS & TELECOMM

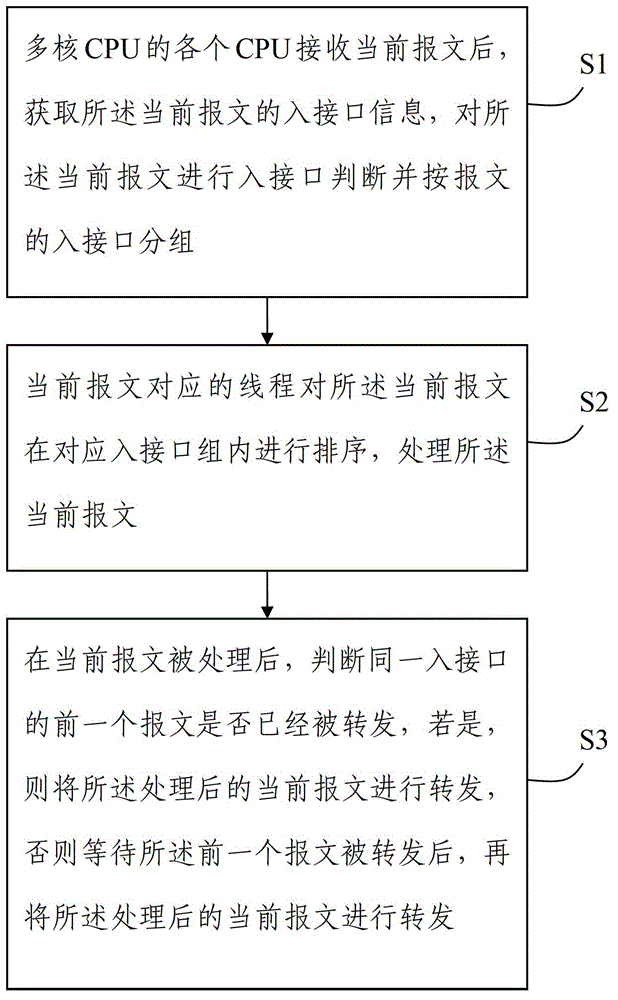

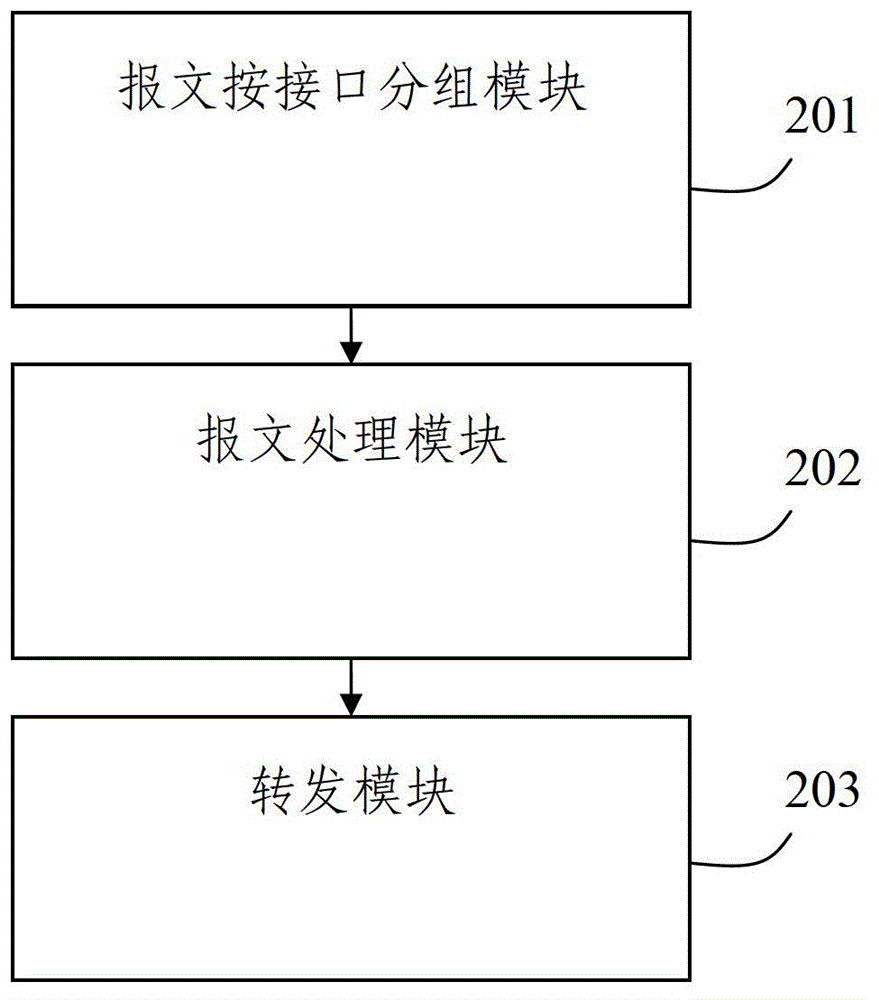

Interface order-preserving method and system of messages of multi-core network device

InactiveCN102891809AAvoid disorderPrecise scope of order preservationData switching networksMulticore cpuComputer science

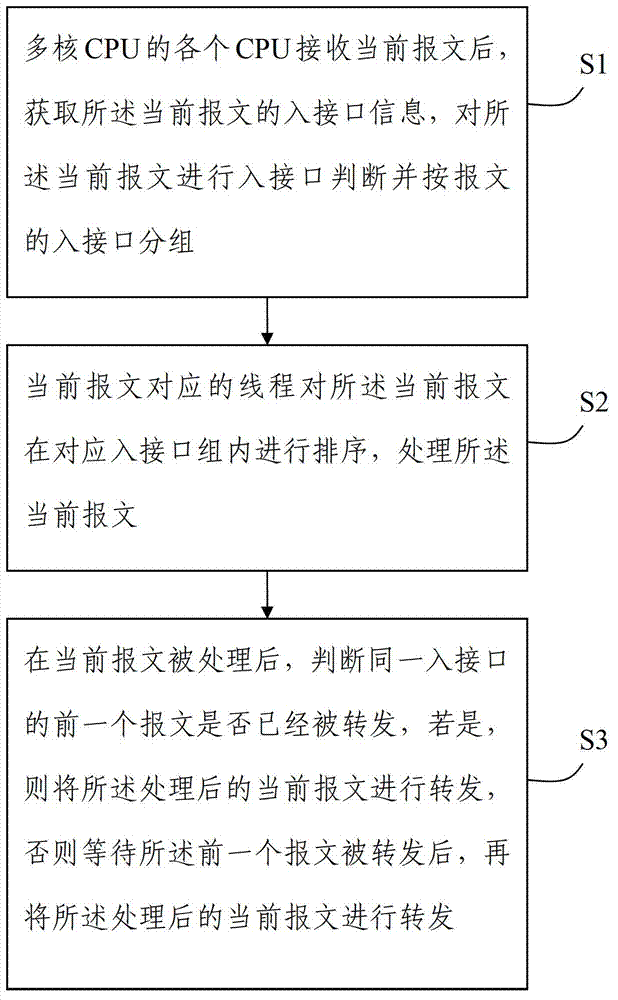

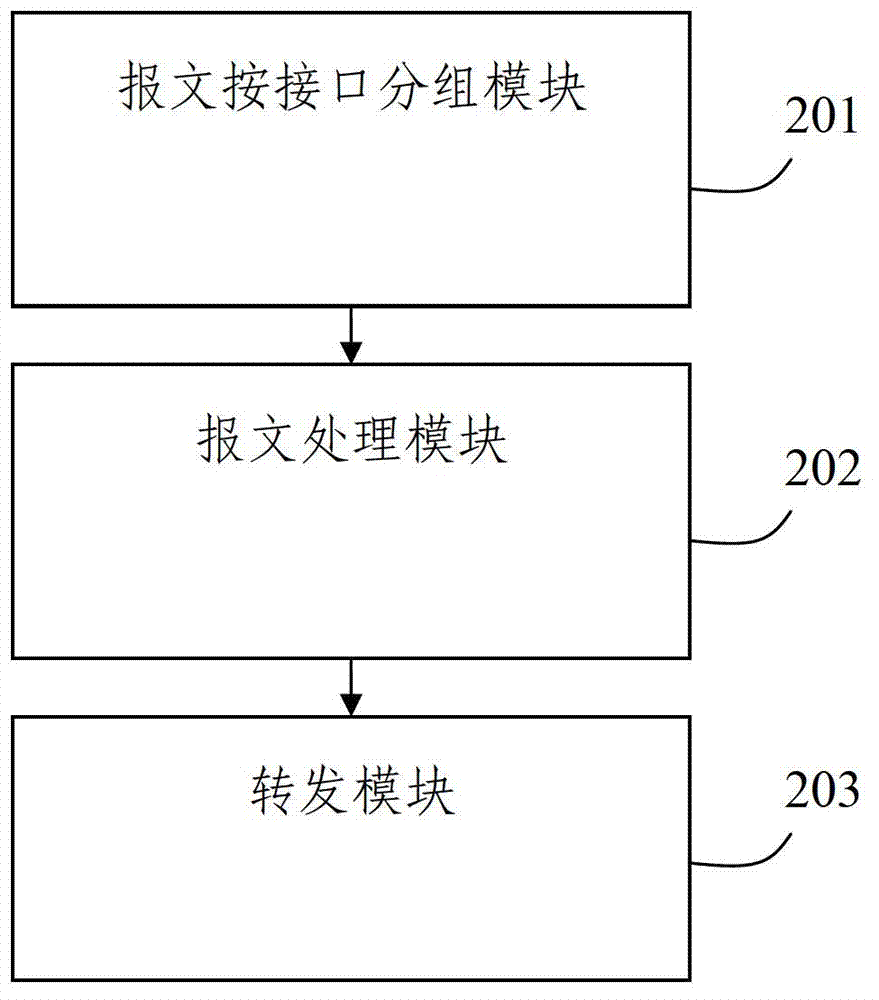

The invention discloses an interface order-preserving method and system of messages of a multi-core network device. The interface order-preserving method comprises the following steps of: S1, after receiving current messages by CPUs of a multi-core CPU, obtaining import interface information of the current messages, carrying out import interface judgment on the current messages and grouping import interfaces of the messages; S2, sequencing the current messages by corresponding threads in corresponding import interface groups, processing the current messages; S3, after the current messages are processed, judging whether the former message of the same import interface is forwarded, if yes, forwarding the processed current messages, otherwise, and after waiting the former message is forwarded, forwarding the processed current messages. In addition, the invention also discloses an interface order-preserving system for realizing the interface order-preserving method. Through judging whether the former message of the same import interface is forwarded, the order preservation of the messages of the same import interface is realized, and the disorder when the messages are sent is prevented.

Owner:OPZOON TECH

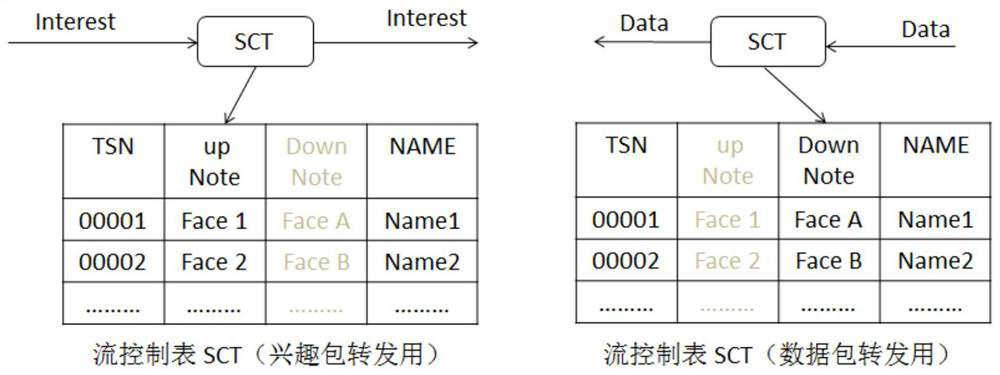

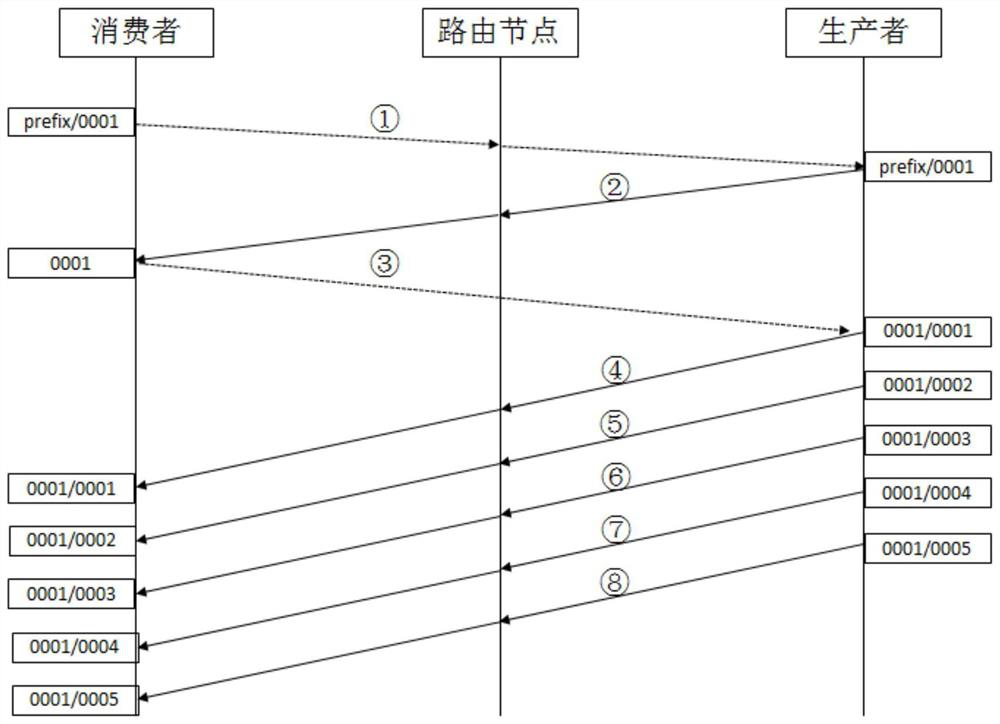

Named data network forwarding method based on flow control

ActiveCN112039781AFast forwardingIncrease forwarding rateData switching networksHigh level techniquesStreaming dataData pack

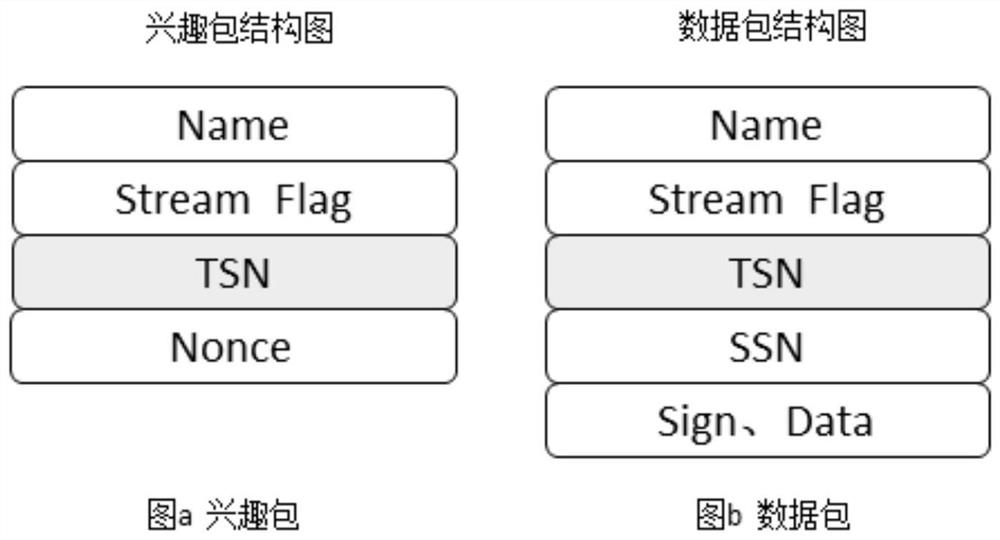

The invention provides a named data network forwarding method based on flow control, and relates to the technical field of computer network data communication. The named data network forwarding methodbased on flow control comprises the following specific steps that S1, when a consumer applies for streaming media data or a large file, a streaming interest packet format is adopted, a streaming transmission sequence number (TSN) is allocated to an interest packet, and then the interest packet is sent out; S2, after arriving at an on-way routing node, if an intermediate routing node has the cachecontent matched with the transmission sequence number, the requested content is directly returned by the intermediate routing node; and if the intermediate node has no corresponding content, the interest packet is forwarded. By adopting a data flow control mode, a transmission serial number and a serial number are allocated to a flow data packet, and a consumer only needs to send two interest packets: a request flow transmission connection establishment interest packet and a flow transmission start interest packet, so that a producer can send all flow data to the consumer packet by packet insequence, and all the data can be pulled back at a time.

Owner:北京同创神州航天科技有限公司

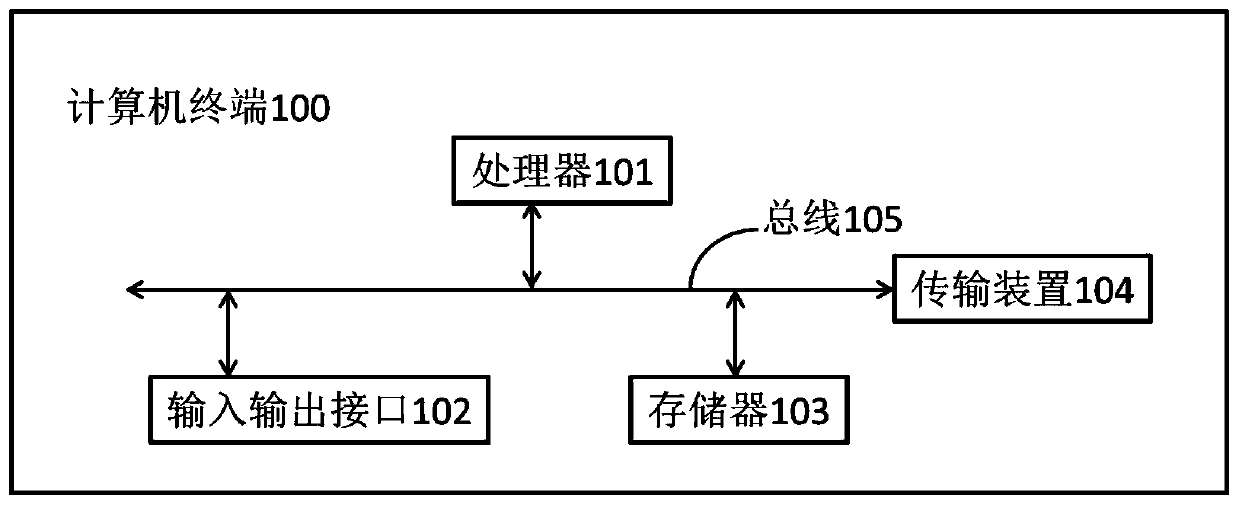

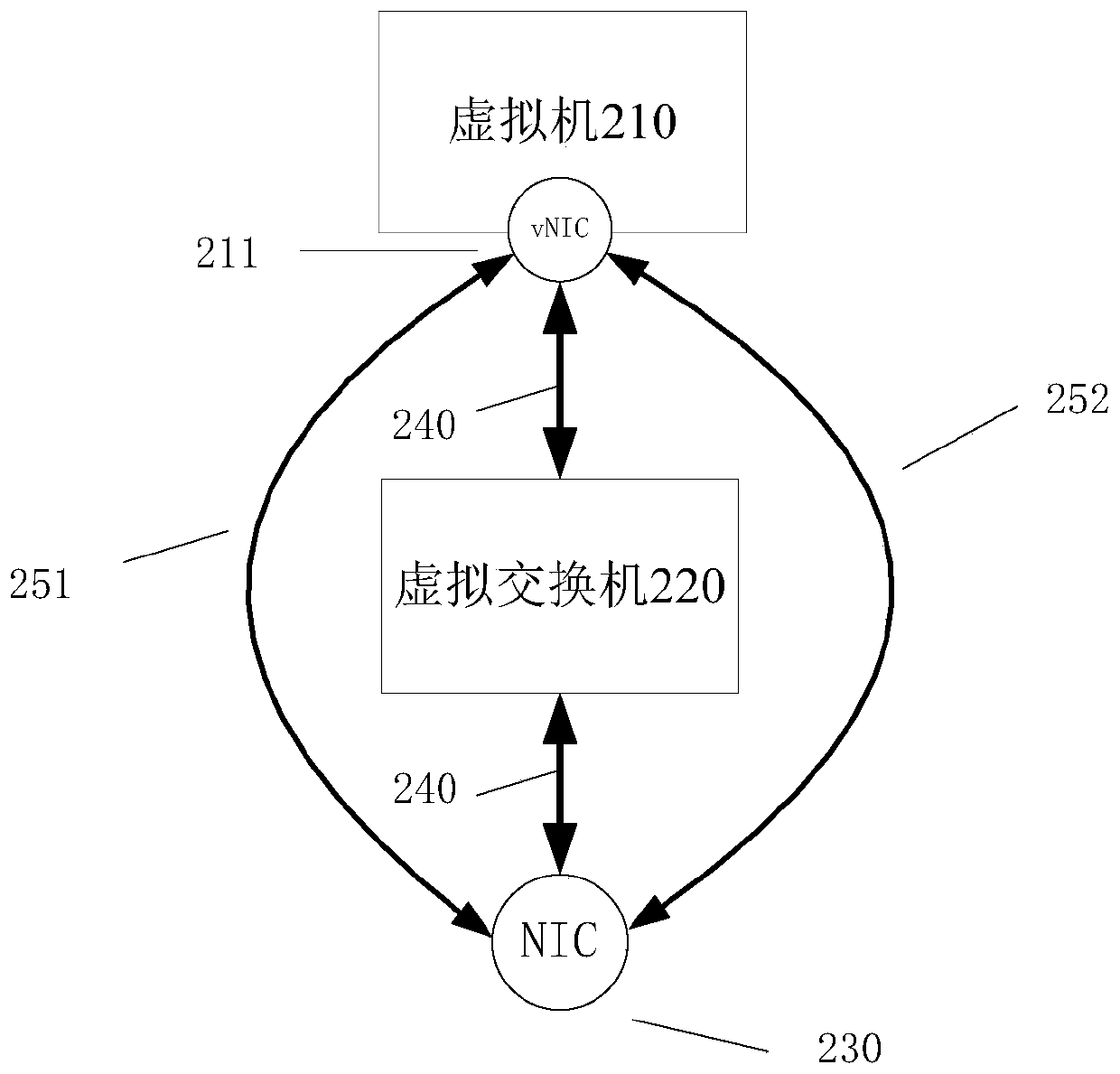

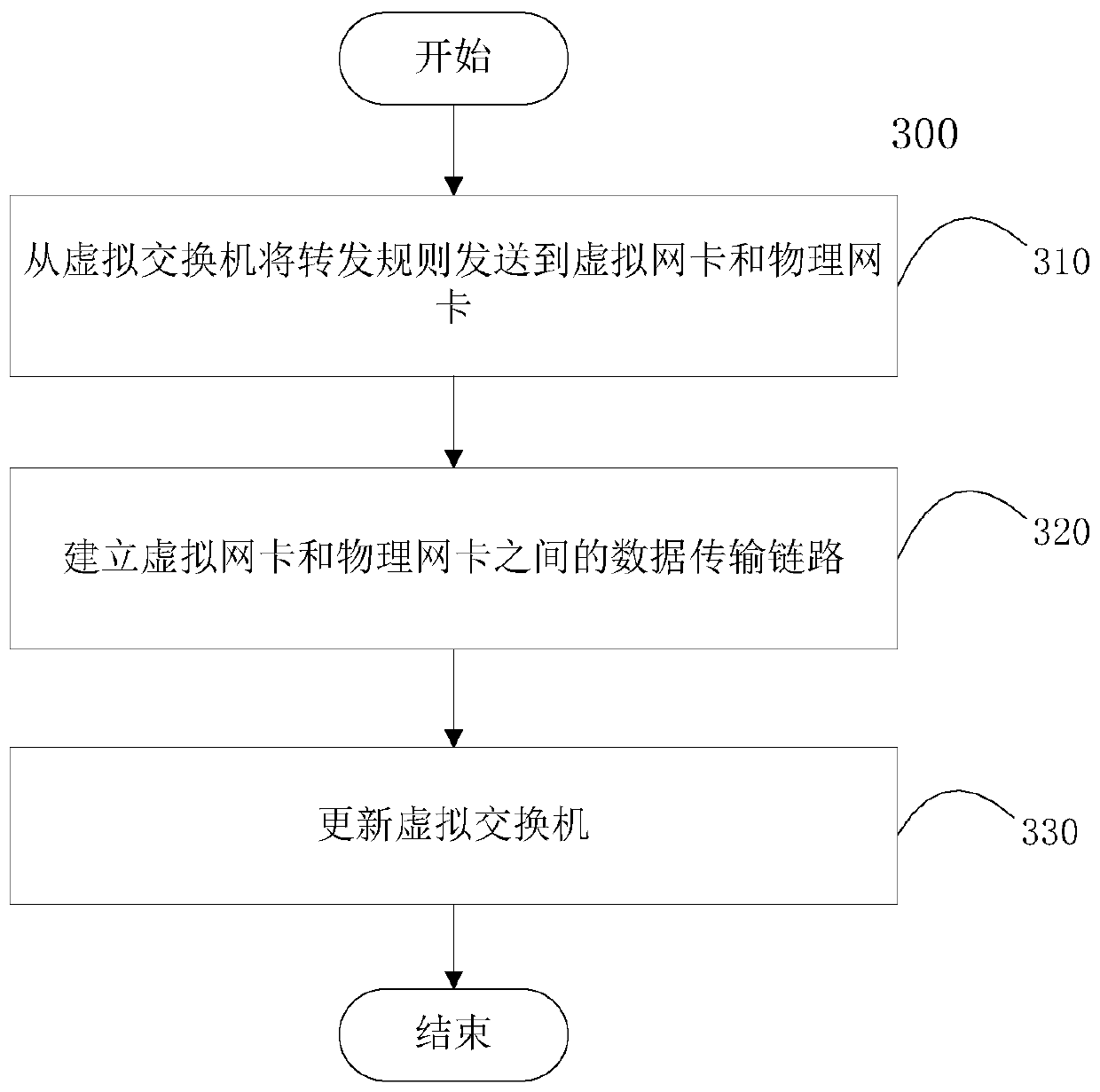

Method and device for updating virtual switch, storage medium and equipment

ActiveCN110149231AImprove performanceFast forwardingData switching networksVirtual switchData exchange

The invention provides a method and a device for updating a virtual switch, a storage medium and equipment. The method comprises the following steps: respectively sending a forwarding rule of a virtual machine which exchanges data with the virtual switch to a virtual network card of the virtual machine and a physical network card corresponding to the virtual machine from the virtual switch; establishing a data transmission link between the virtual network card and the physical network card, so that the virtual network card and the physical network card directly forward data of the virtual machine through the data transmission link according to a forwarding rule; updating virtual switches.

Owner:UCLOUD TECH CO LTD

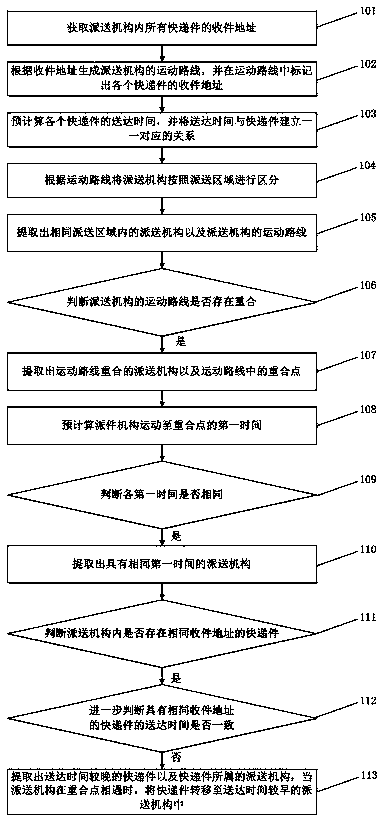

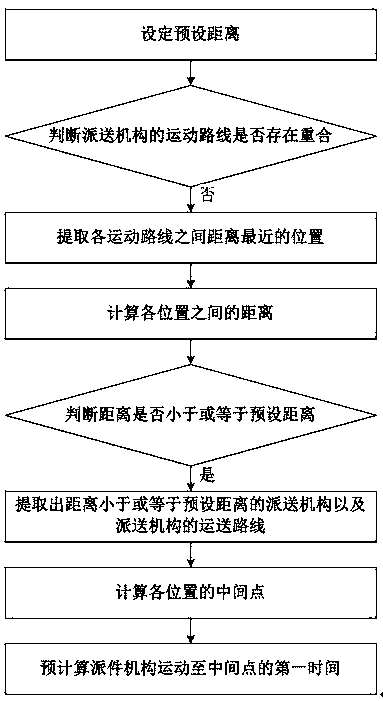

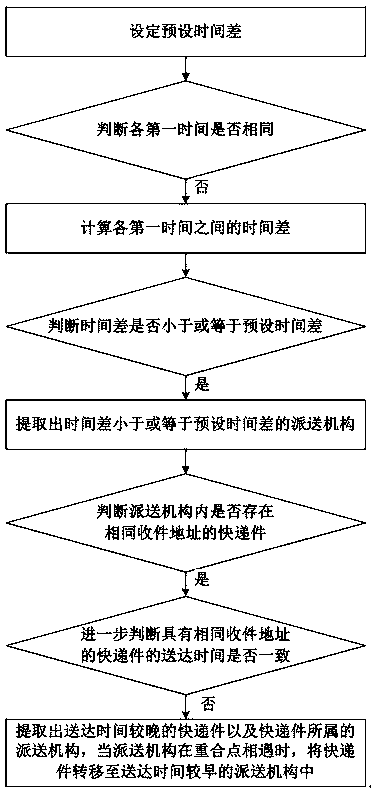

Express delivery method and system for logistics transportation

The invention provides an express delivery method and system for logistics transportation. The method comprises steps that the delivery address of an express is acquired; the movement route of a delivery organization is generated, and the delivery address of the express is marked in the movement route; the delivery time of each express is pre-calculated; delivery organizations are distinguished according to delivery areas; the delivery organizations within the same delivery areas are extracted; if delivery routes of the delivery organizations overlap, a coincidence point in the motion routes is extracted; the first time when the delivery organizations move to the coincidence point is pre-calculated; if the first time is the same, the delivery organizations having the same first time are extracted; if expresses of the delivery organizations have the same delivery addresses, whether the delivery time of the expresses is consistent is determined; if not, when the delivery organizations meet at the coincidence point, the expresses with the later delivery time are transferred to the delivery organizations with the earlier delivery time, and the delivery time of the expresses, the movement routes of the delivery organizations and the first time of the delivery organizations arriving at the coincidence point are updated in real time.

Owner:仝相宝

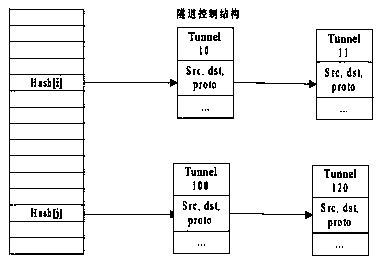

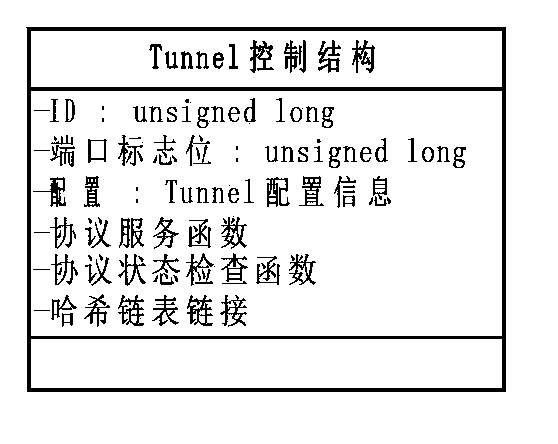

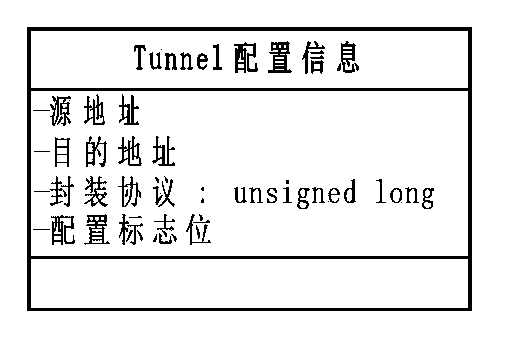

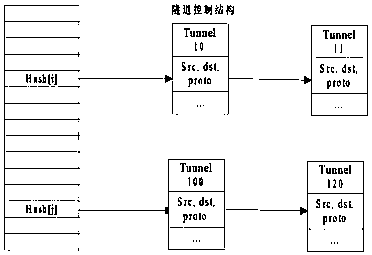

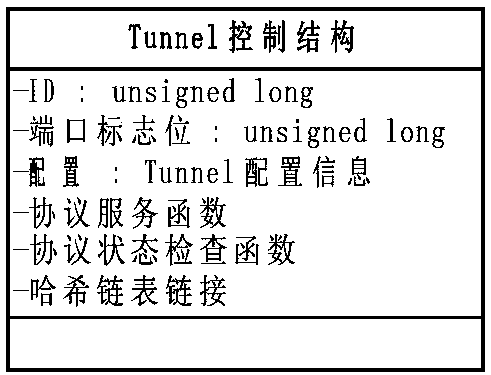

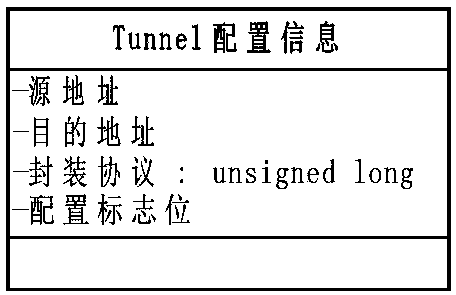

Realization method and message forwarding method of IPv6 tunnel on multi-core platform

ActiveCN103780469AFast forwardingImprove forwarding performanceNetworks interconnectionMessage processingForward speed

The invention discloses a realization method and a message forwarding method of an IPv6 tunnel on a multi-core platform. In the realization method of the tunnel, one Hash value is calculated for each configured tunnel according to the configured source address and a target address of the tunnel, and a tunnel control structure comprising other configurations is inserted into a corresponding Hash linked list. In the message forwarding method, a flow concept is introduced to a common flow. At the beginning of message processing at a protocol stack, one dflow list item is initialized, and each module through the common flow mounts the respective-needed information on the list item. The dflow list item is confirmed before successful forwarding, then a series of list lookup work can be saved for the following similar messages and rapid forwarding can be directly realized. Inquiring speed of the tunnel can be accelerated in receiving an IPv4 message without influencing the number of the tunnel. Meanwhile, the forwarding dflow process can be established so that repetitive inquiring of configuration is avoided and thus forwarding speed is accelerated.

Owner:SHANGHAI BAUD DATA COMM

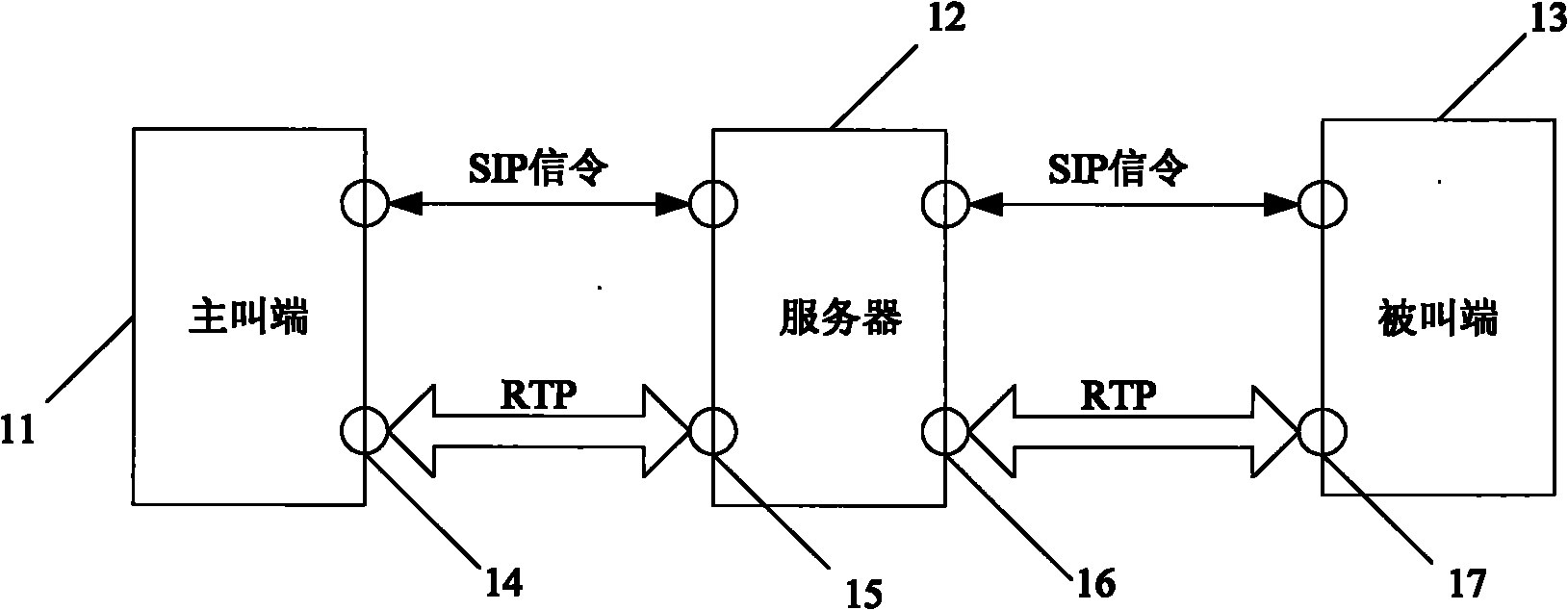

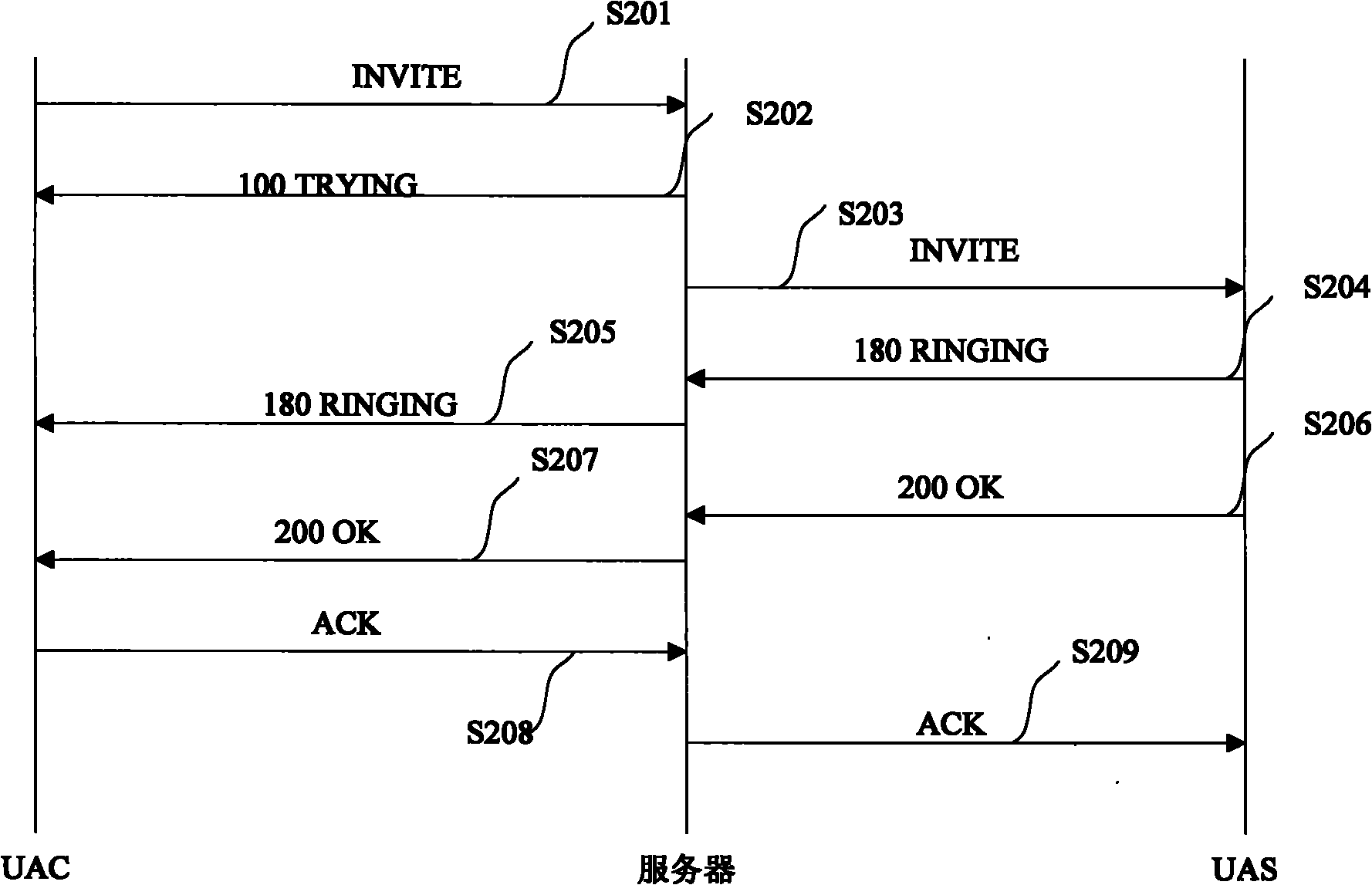

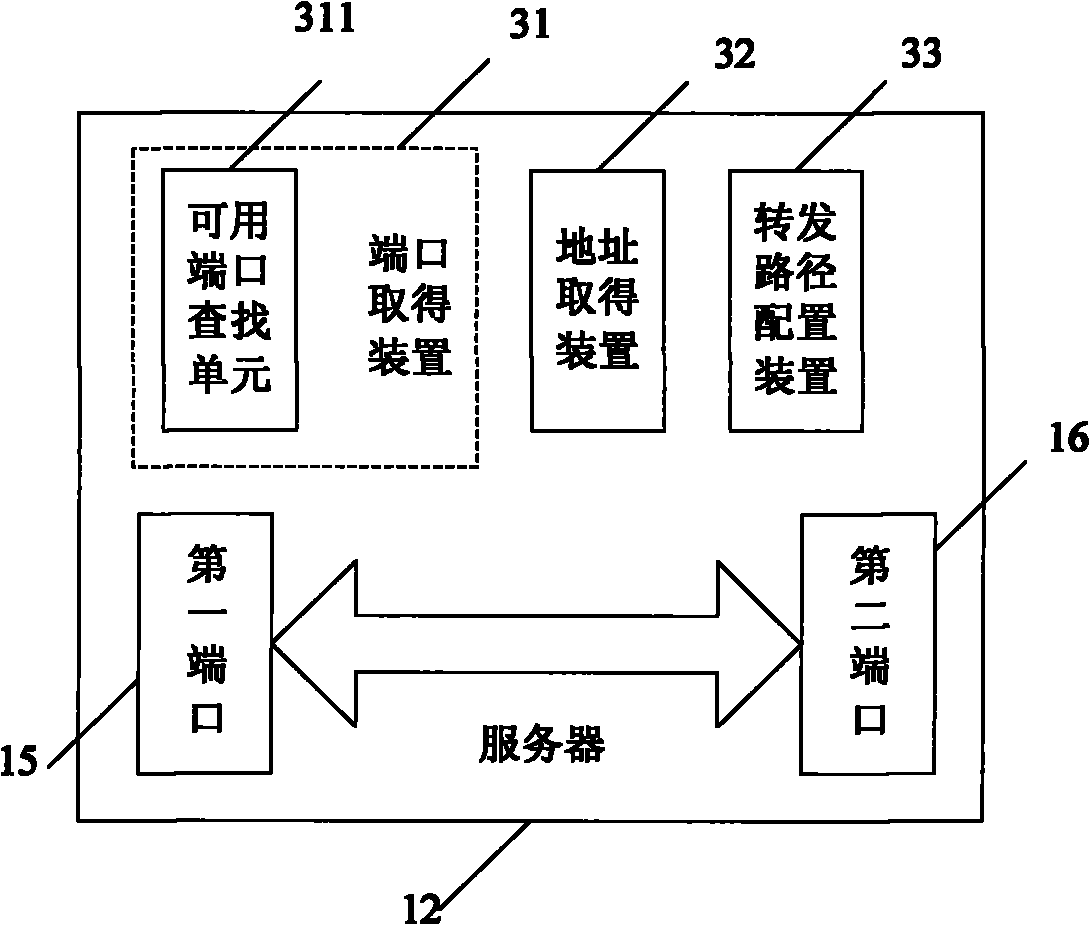

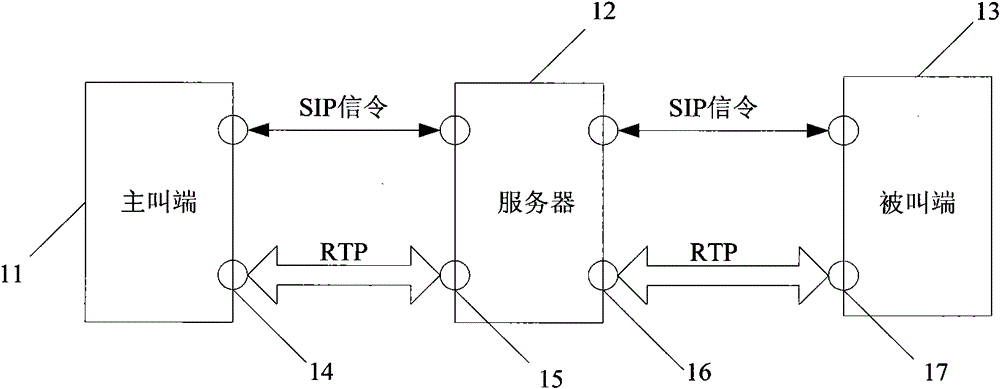

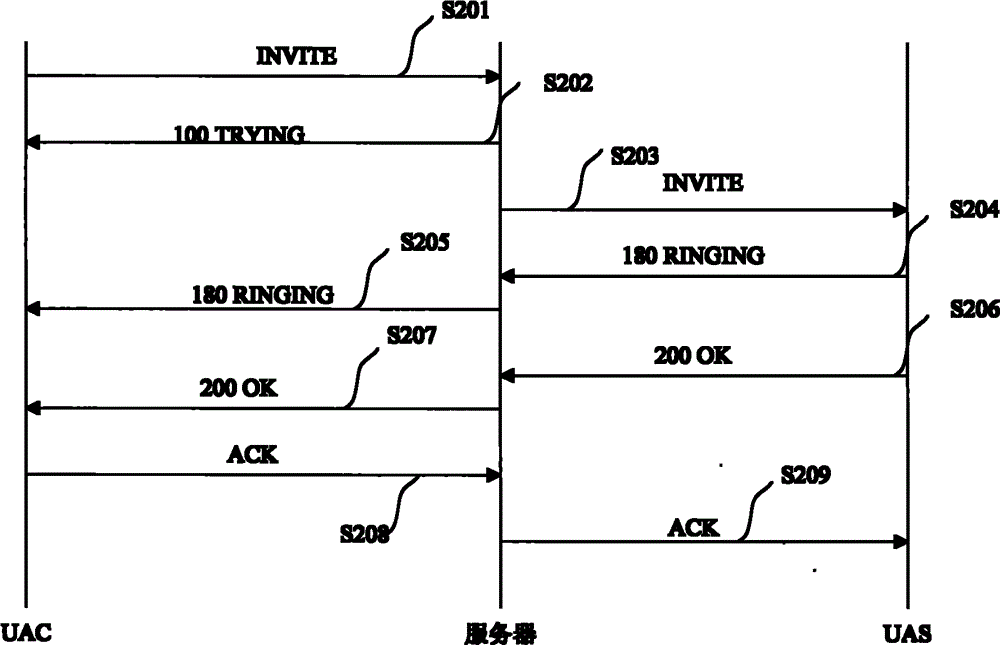

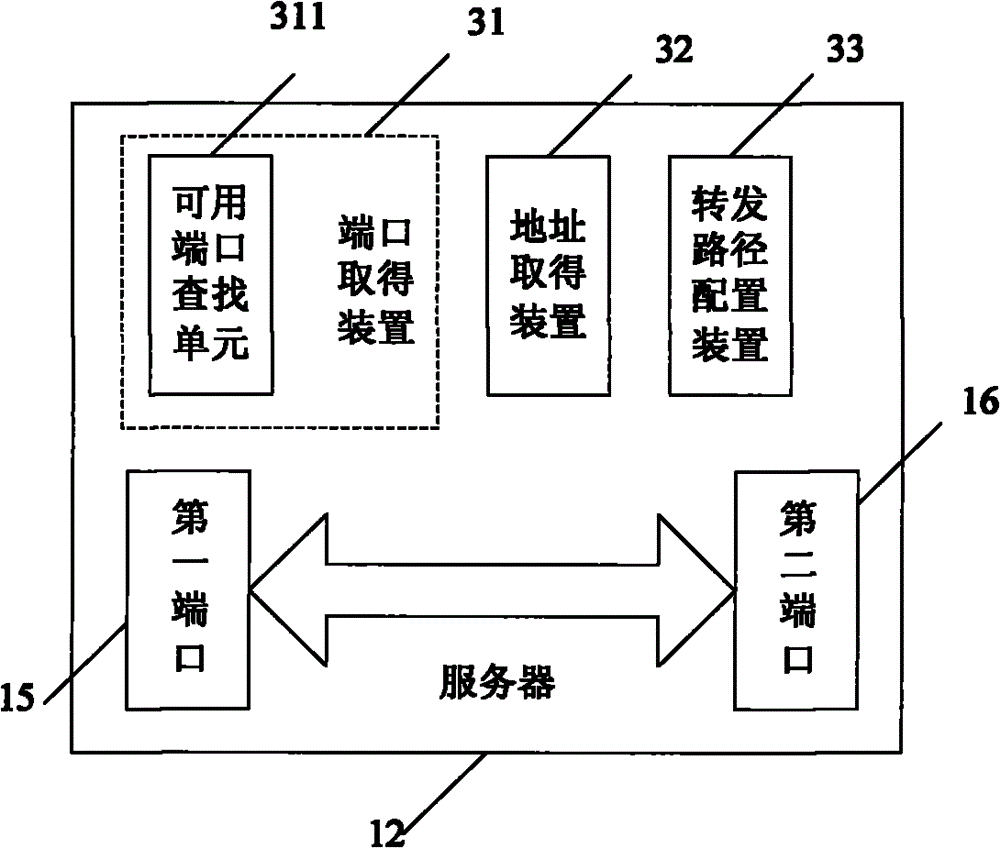

Multimedia stream transmission method and system

ActiveCN101917409AUses less kernel resourcesFast forwardingWireless network protocolsTransmissionComputer networkComputer science

The invention relates to a multimedia stream transmission method. The method comprises the following steps of: obtaining a port number of a calling terminal multimedia stream transmitting port, the port number of a called terminal multimedia stream transmitting port, a first port number corresponding to the calling terminal multimedia stream transmitting port and a second port number corresponding to the called terminal multimedia stream port transmitting by using signaling sent by a calling terminal, the response made by the called terminal after the called terminal receives a signaling forwarded by a server and a port matching list set in the server; and forwarding the received multimedia stream between the first and second ports. The invention also relates to a multimedia stream transmission system. The multimedia stream transmission method and the multimedia stream transmission system of the invention have the advantages of relatively few occupied kernel resources and relatively high forwarding speed.

Owner:深圳黑洞光科技有限公司

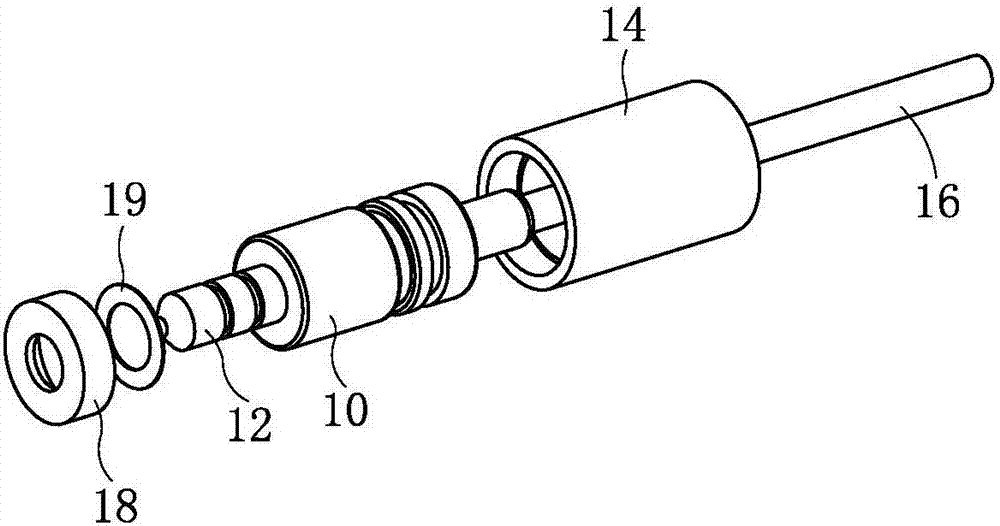

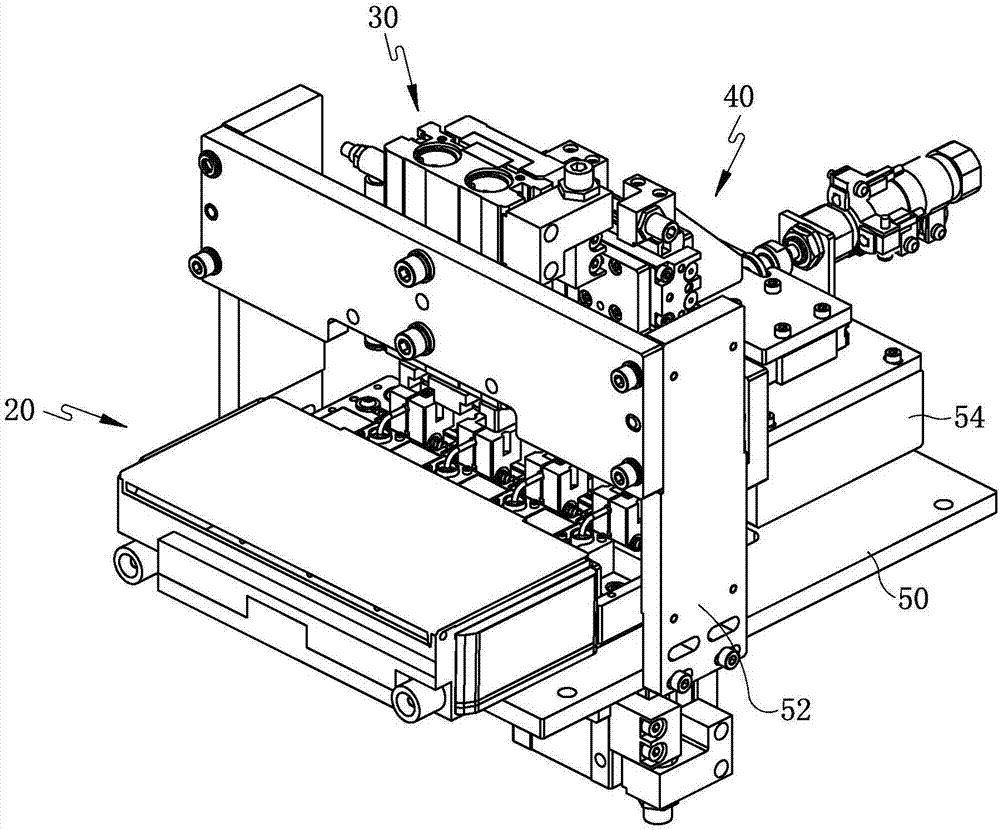

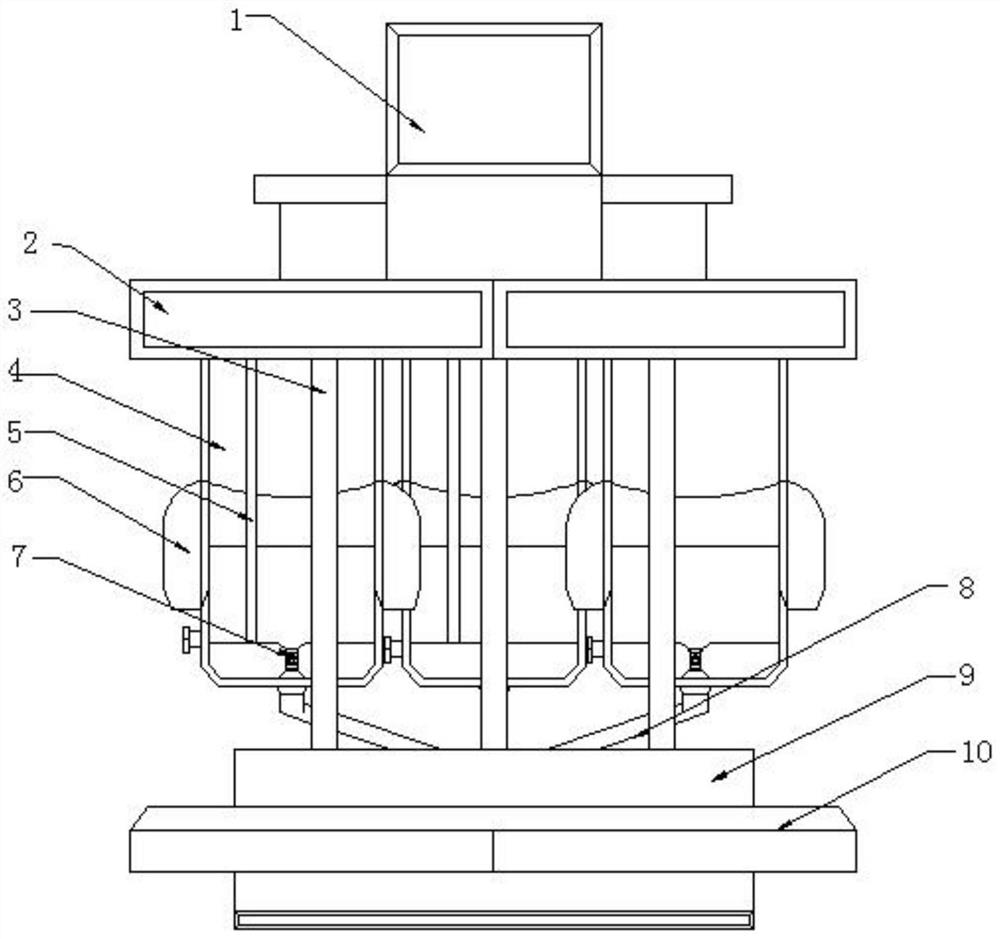

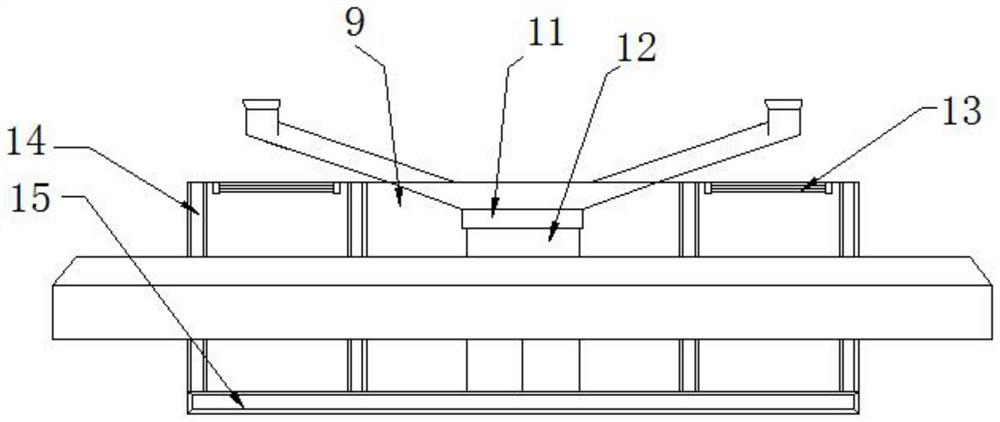

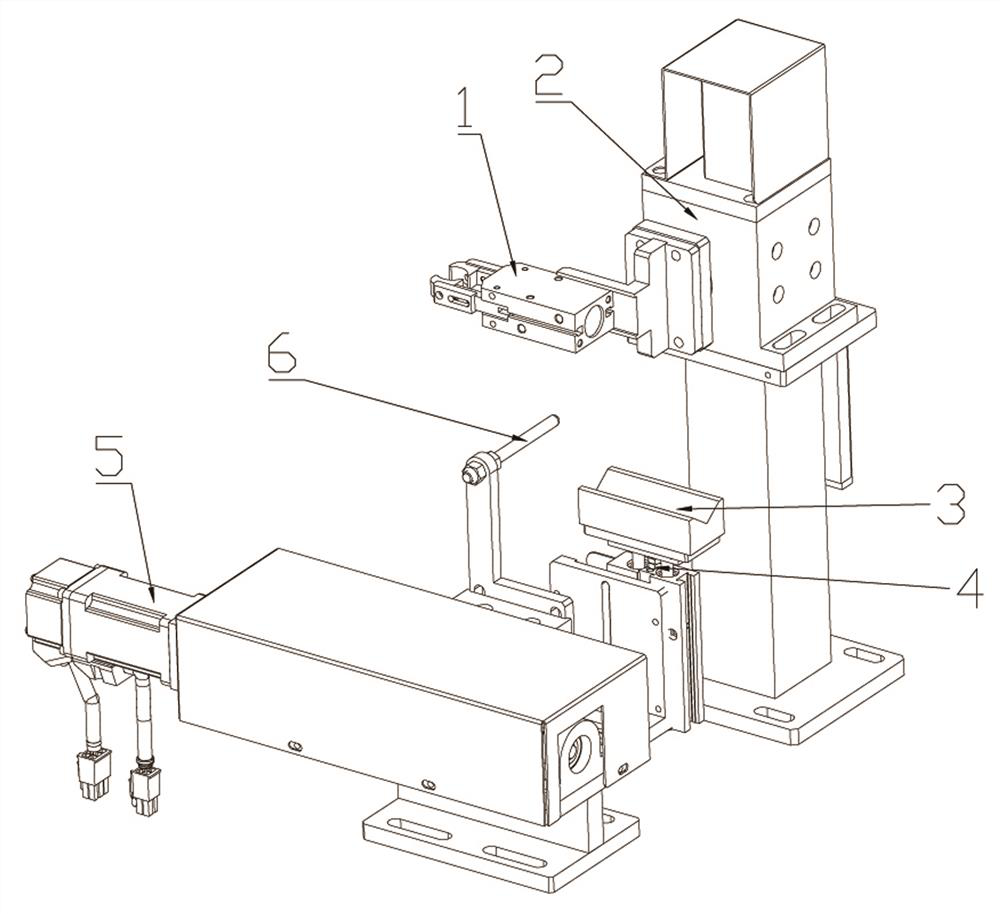

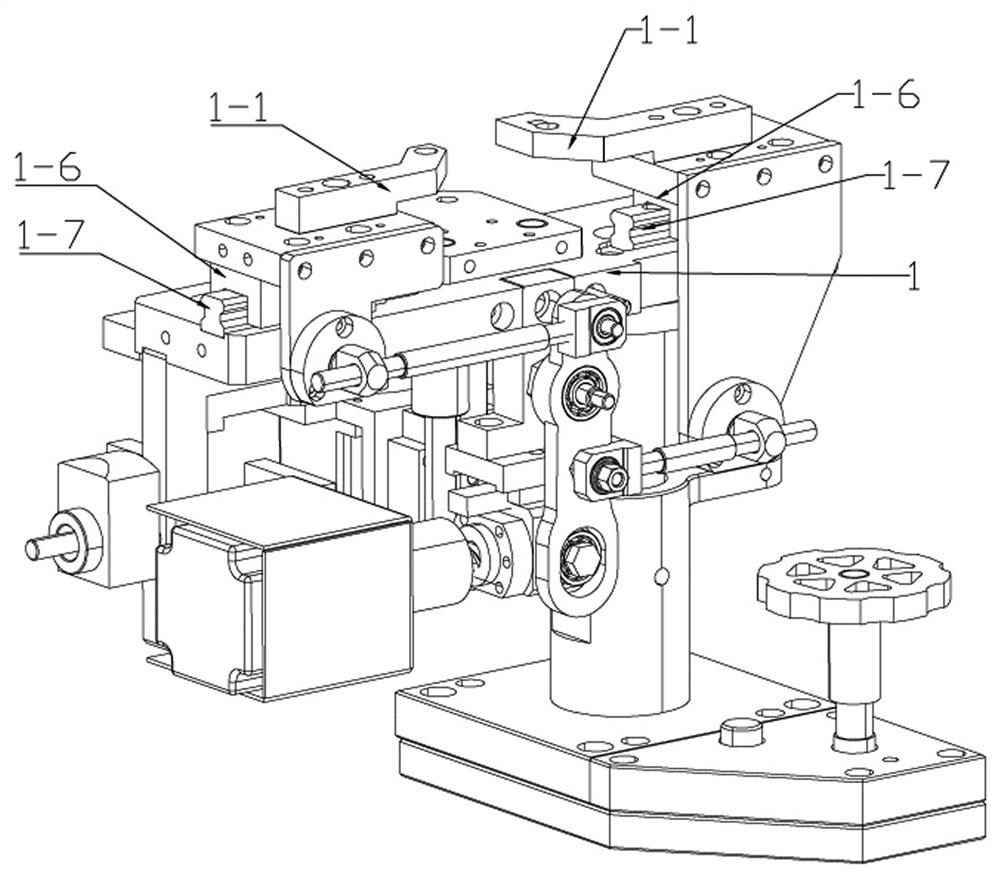

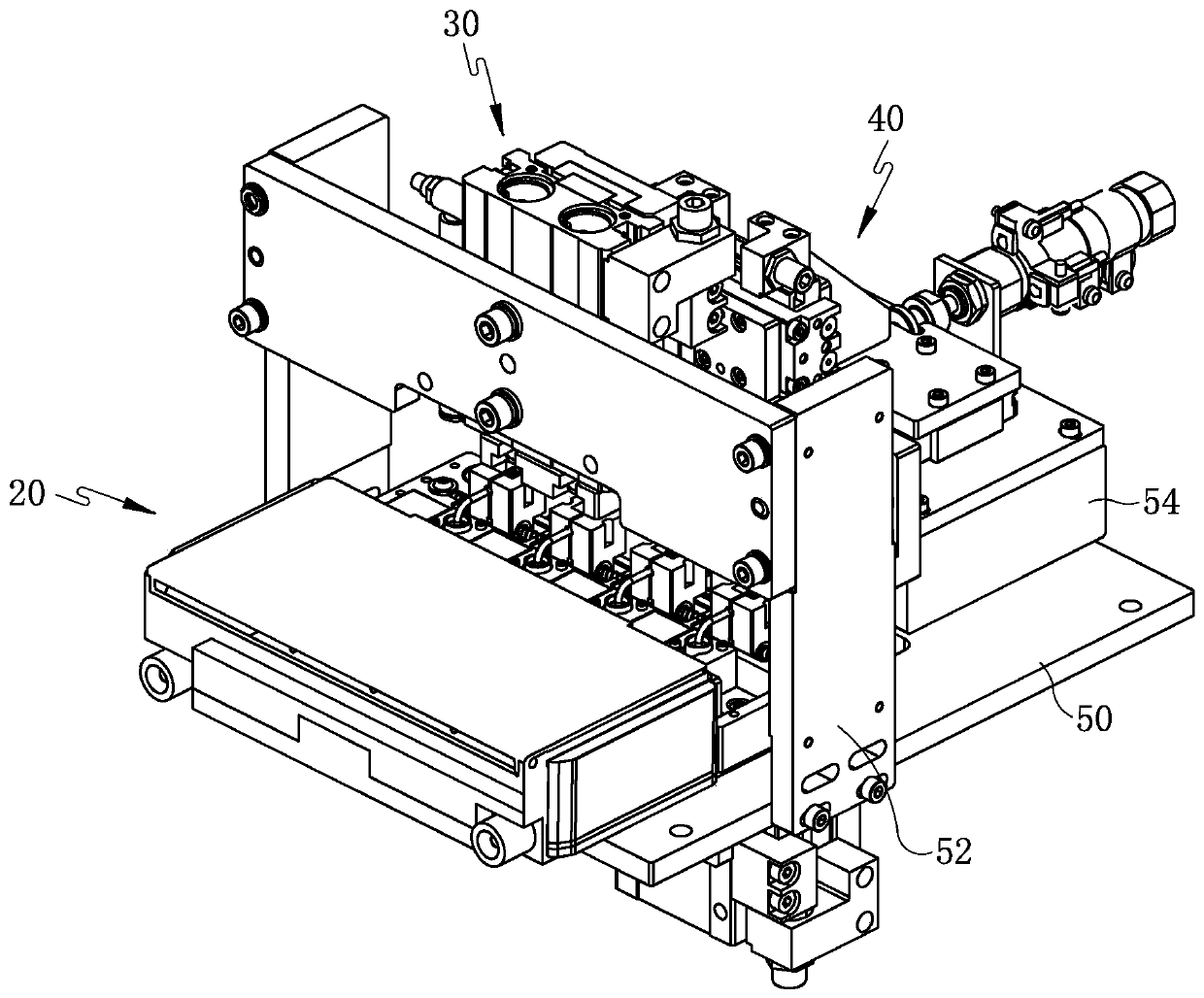

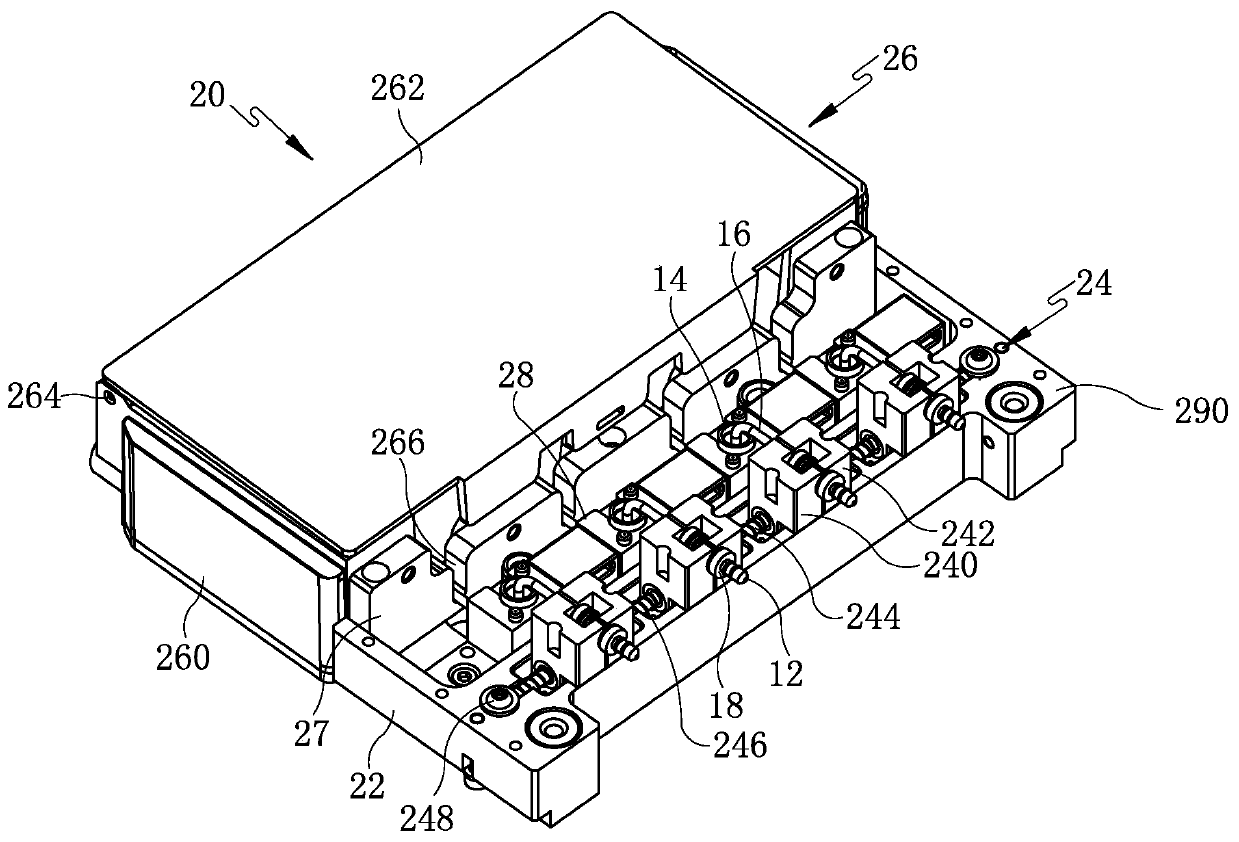

Locating and shaping device

ActiveCN107008773AImprove consistencyAchieve shapingMetal-working feeding devicesPositioning devicesEngineering

The invention discloses a locating and shaping device and relates to the technical field of product shaping equipment. The locating and shaping device comprises an attraction locating device and a shaping device. The attraction locating device comprises an attraction locating assembly capable of longitudinally moving. The attraction locating assembly comprises multiple clamping blocks capable of transversely moving. The clamping blocks can provide transverse clamping force for products. The shaping device comprises an upper shaping device body and a lower shaping device body, wherein the upper shaping device body and the lower shaping device are oppositely arranged on the upper side and the lower side of an installation base plate correspondingly. The portion, corresponding to the shaping device, of the installation base plate is provided with a vertically-through hole. The upper shaping device body and the lower shaping device body each comprise a shaping plate capable of moving up and down. Each shaping plate is provided with shaping grooves adaptable to the structure of components to be shaped. The locating and shaping device can achieve accurate locating of the product, the shaped product components are good in consistency, the shaping efficiency is high, the yield of the products can be improved, automatic product is facilitated, and the production cost of an enterprise is reduced.

Owner:GOERTEK INC

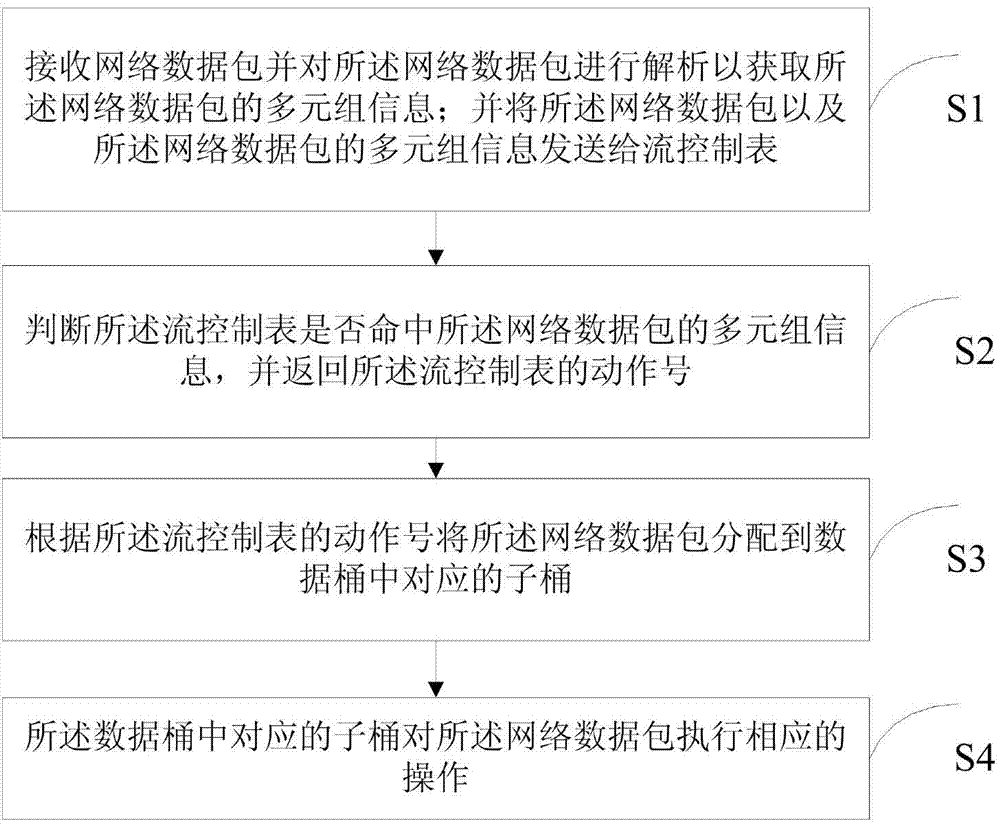

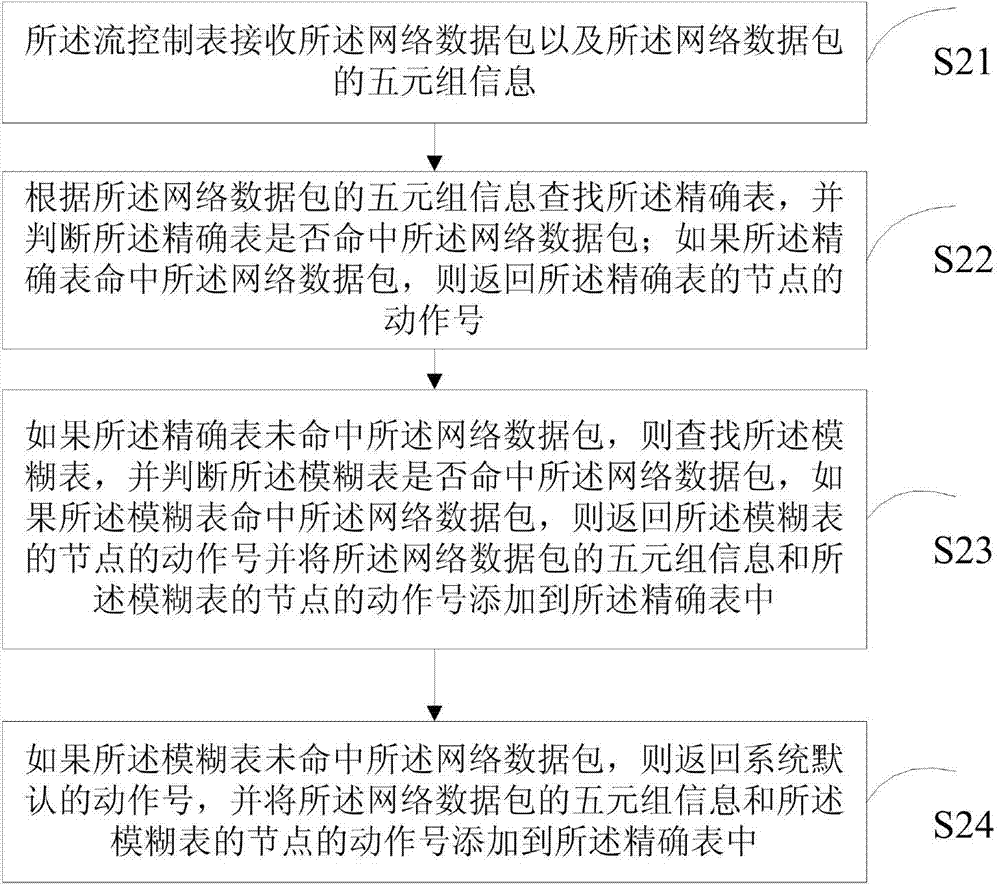

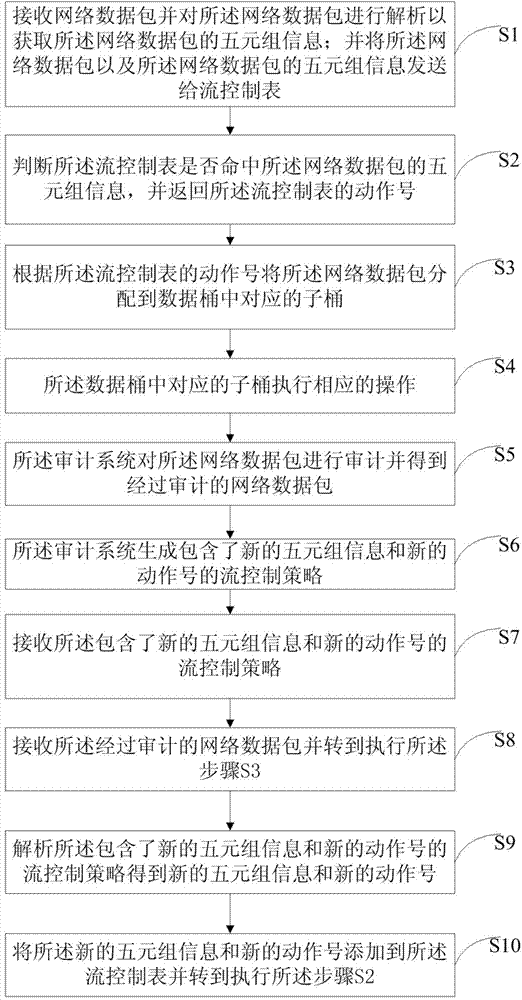

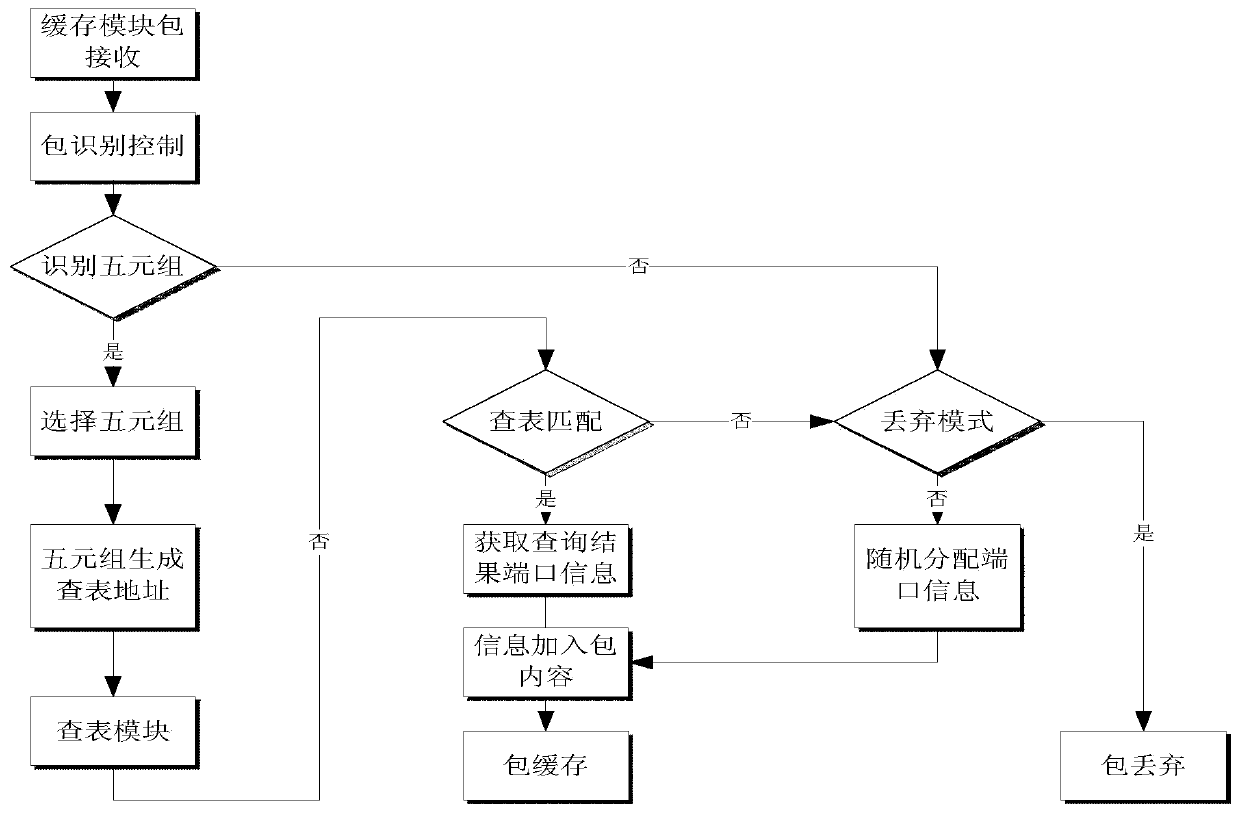

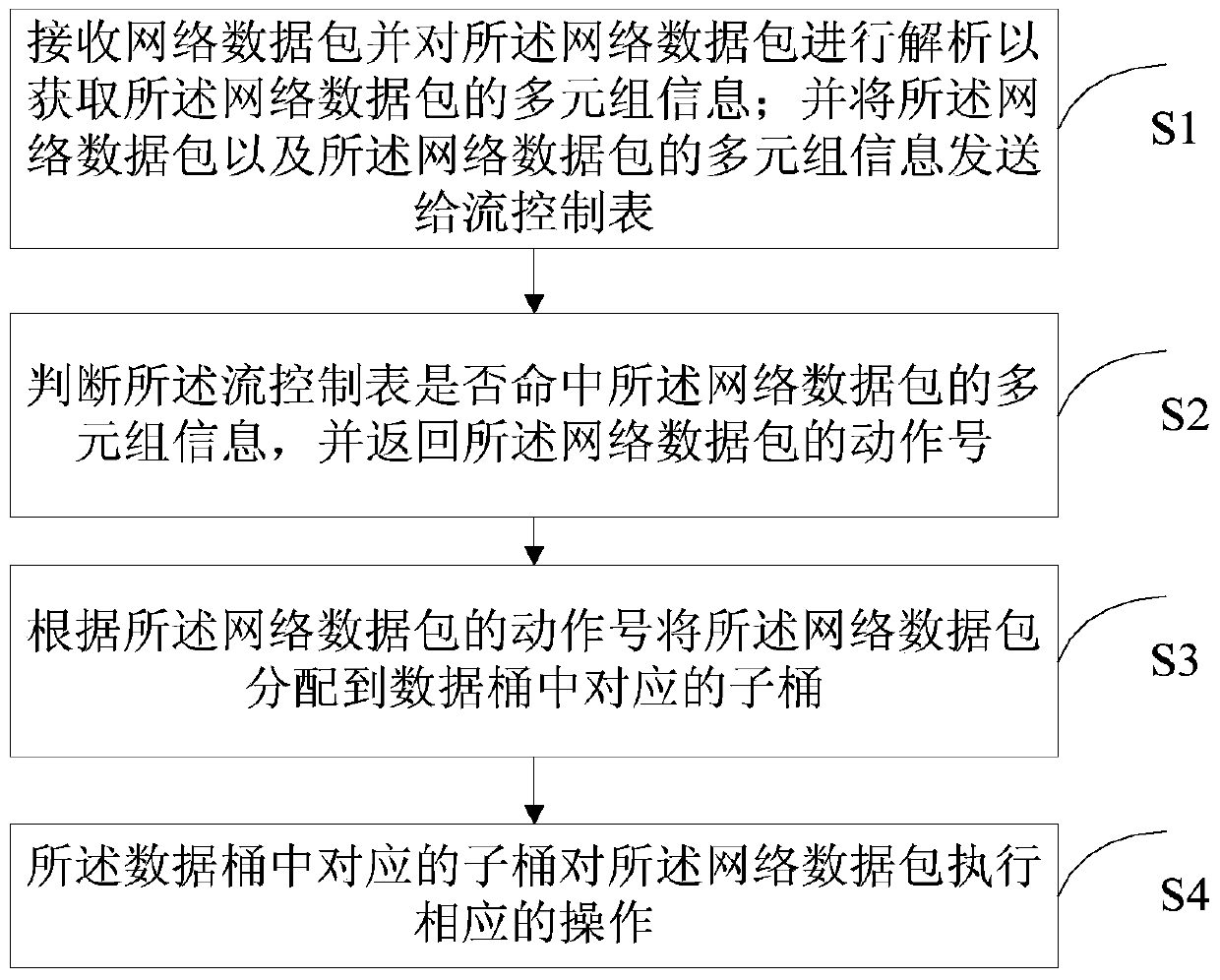

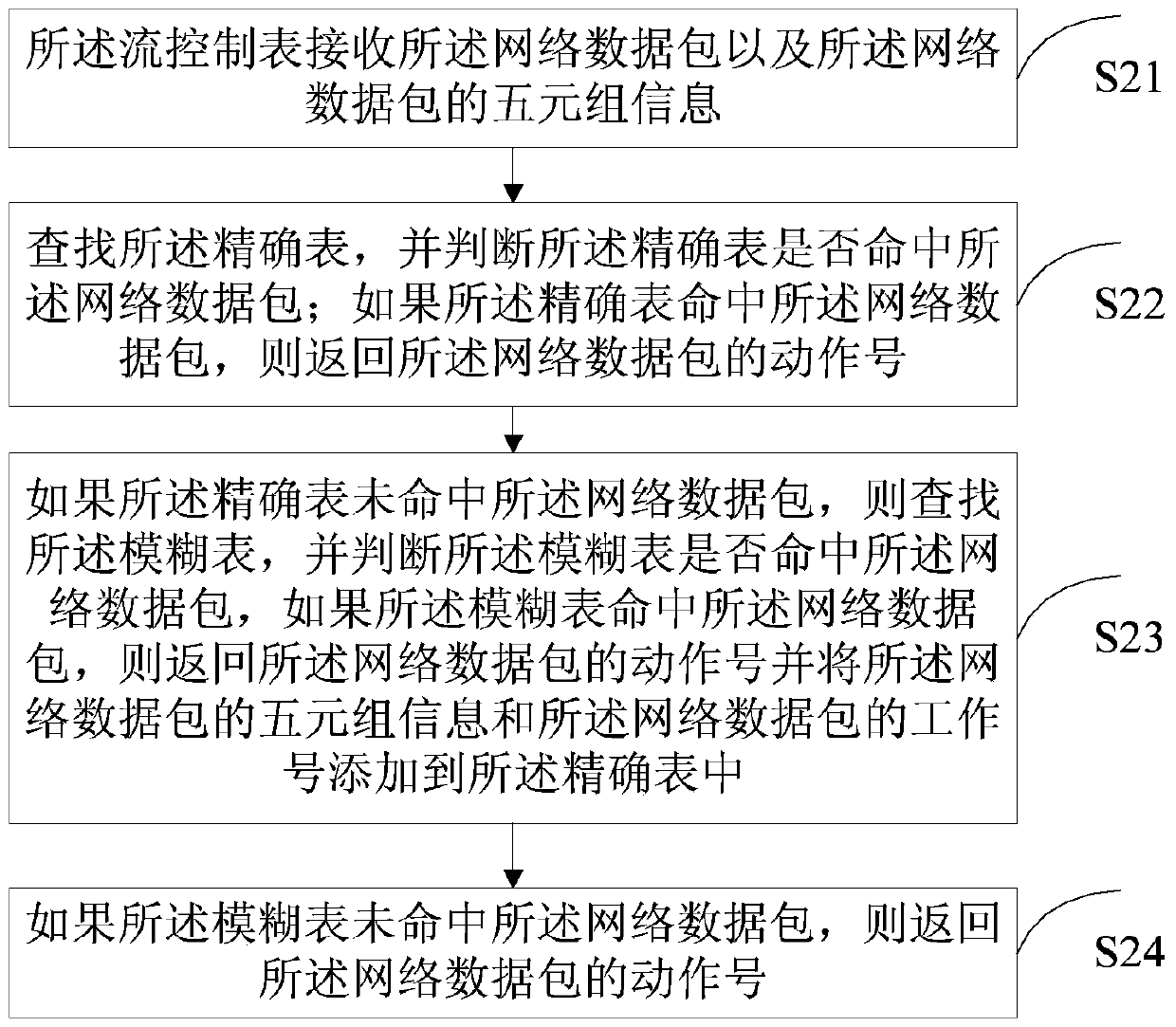

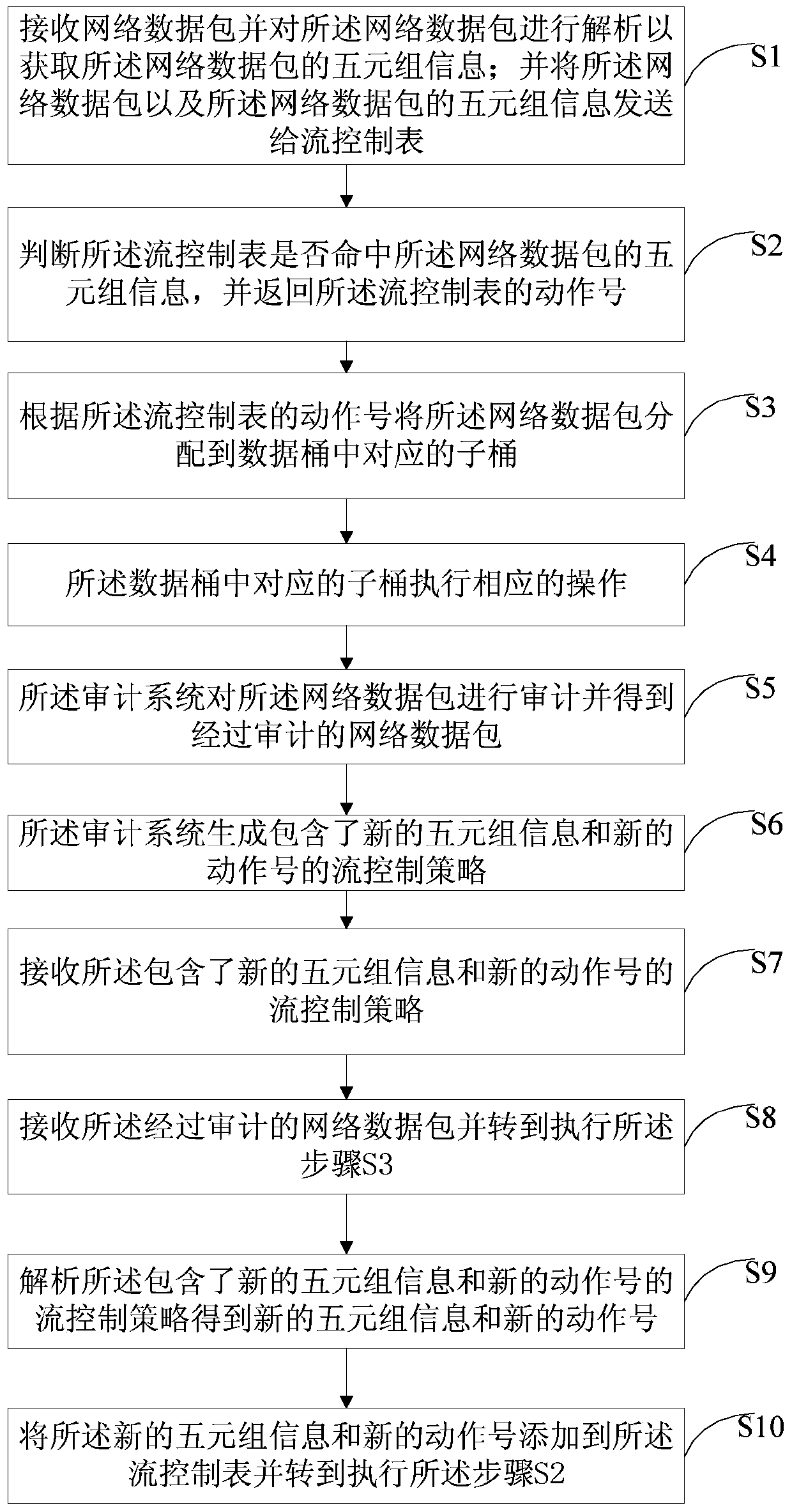

Serial data stream auditing control method and serial data stream auditing control system

ActiveCN104753726AFast forwardingImprove forwarding efficiencyData switching networksReal-time computingData pack

The invention discloses a serial data stream auditing control method. The method comprises a first step of receiving a network data package and analyzing the network data package to obtain multi-element-array information of the network data package, and sending the network data package and the multi-element-array information thereof to a stream control table; a second step of judging whether the stream control table hits the multi-element-array information of the network data package, and returning an action number of the stream control table; a third step of allocating the network data package to a corresponding secondary bucket of a data bucket according to the action number of the stream control table; and a fourth step of performing corresponding operation on the network data package by the corresponding secondary bucket of the data bucket. Through adoption of the method, the network throughput of an auditing system can be improved; the forwarding efficiency and auditing flexibility of a serial auditing system are also guaranteed; and the auditing system can forward the data at a high speed. The invention also discloses a serial data stream auditing control system.

Owner:SURFILTER NETWORK TECH

Method and equipment for customizing batching and color-matching daily chemical product

PendingCN108312566ASimple and efficient operationMeet individual needsPackaging toiletriesPackaging cosmeticsProduct ContainersColor matching

The invention relates to a method and equipment for customizing a batching and color-matching daily chemical product. The method for customizing the batching and color-matching daily chemical productcomprises the following steps: A, arranging a color code input device on a color matching machine display screen or app; B, storing colorless aggregates in a batching output device and storing base pigments in the batching output device; C, starting a computer program in the step A to extrude the matching output device and extruding the set dosage of the colorless aggregates and the base pigmentsinto a mold for mixing; D, melting the mixed colorless aggregates and base pigments into liquid through a heating container and performing ultrasonic vibration stirring; E, after uniform stirring, putting the mold in a cooling container for shaping into a solid; F, putting the solid with the mold obtained in the step E in a product container and generating suction force in the product container toenable a product to be divorced from the mold. The method and the equipment provided by the invention have the beneficial effects that the operation is simple and convenient, and immediacy and diversity are higher.

Owner:每日优养科技(北京)有限公司

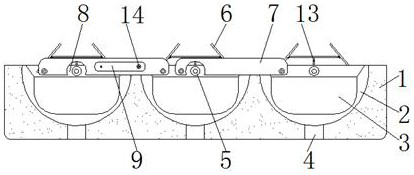

Rainwater collecting and utilizing system for energy-saving greenhouse

ActiveCN113027049AEasy to useEnlarging the notch areaBatteries circuit arrangementsFatty/oily/floating substances removal devicesRainwater harvestingStormwater

The invention relates to the technical field of greenhouse rainwater collection, and particularly relates to a rainwater collecting and utilizing system for an energy-saving greenhouse. The rainwater collecting and utilizing system comprises a box body, wherein a groove is formed in the top surface of the box body in the length direction; rotatable collecting grooves are formed in the groove; the collecting grooves are used for collecting rainwater; the end surfaces of one sides of the adjacent collecting grooves are connected through connecting plates; a movable plate is rotationally mounted on one side, facing the inner wall of the box body, of one connecting plate through a bearing part; a driving shaft is led out of the movable plate; and the end part of the driving shaft penetrates through the box body and extends to the outside of the box body. The rainwater collecting and utilizing system solves the problems that rainwater collected by utilizing greenhouse rainwater collecting equipment is contaminated by impurities in the long-term external arrangement process and the rainwater receiving rate is not high. The rainwater collecting and utilizing system can ensure that rainwater after standing is quickly transferred out and is convenient to utilize, and can further enlarge the area of a rainwater receiving notch and improve the rainwater receiving rate.

Owner:江苏嘉仁建设工程有限公司

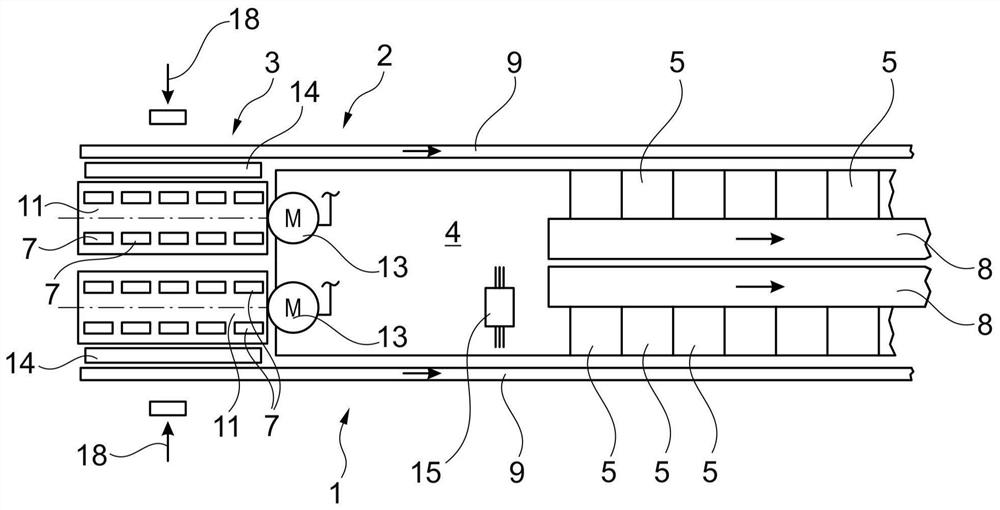

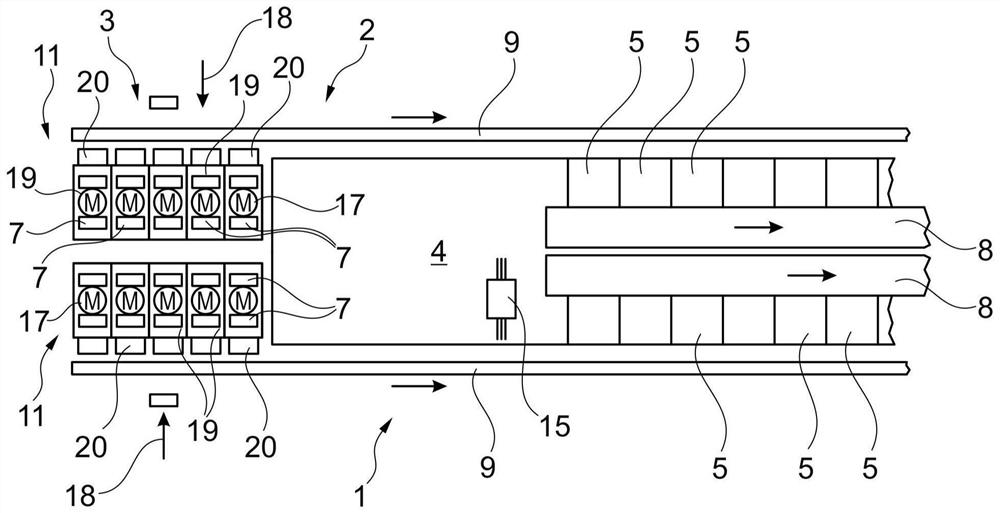

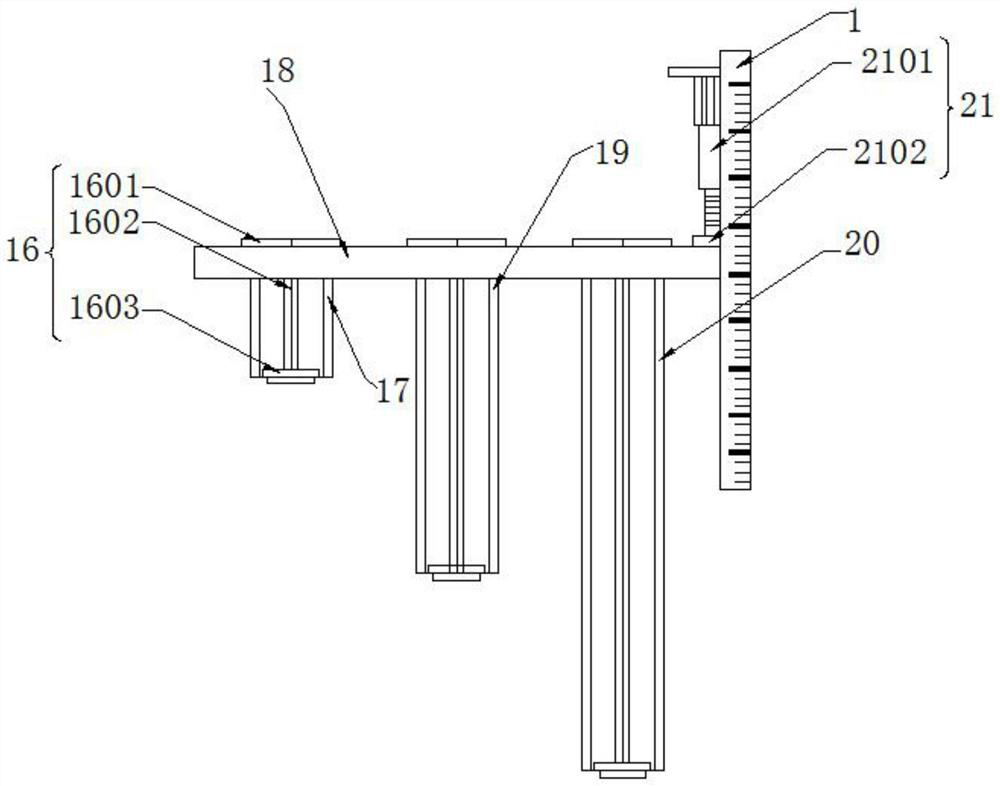

Tube storage and transport device for textile machine producing cross-wound packages

ActiveCN111824860ALess construction effortFast deliveryConveyorsFilament handlingConveyor beltPhysics

The invention relates to a tube storage and transport device (2) for a textile machine producing cross-wound packages (1), which has a plurality of similar workstations (5) arranged side-by-side on both longitudinal machine sides, having a central tube magazine (3) and two empty-tube conveyor belts (9) arranged in the region of the longitudinal machine sides. To improve the known tube storage andtransport devices (2), and in particular to optimize the clock times that can be achieved during the empty-tube delivery, the tube magazine (3) has at least two elevator units (11), that the elevatorunits (11) have stacked and vertically displaceable holders (16) for empty tubes (7), that the holders (16) are designed for the empty tubes to be set down in a manner oriented the longitudinal direction of the machine, and that each of the elevator units (11) is connected to one of the empty-tube conveyor belts (9) and is designed in such a way that empty tubes (7) are removed from the elevator units (11) from the longitudinal machine side and transferred onto the empty-tube conveyor belts (9).

Owner:SAURER SPINNING SOLUTIONS GMBH & CO KG

Multi-jumper radio relay communication system and its download data transmission method

ActiveCN101150498BNo need to change protocol structureReduce overheadData switching by path configurationNetwork data managementCommunications systemRadio relay

The invention discloses a downlink data transmitting method which is applied to a multi-hop wireless relay communication system. The communication system includes: a base station and one or more relay stations. The base station and the relay stations are node devices. The method includes the following steps: respectively arranging a route database in the node devices, the route database storing a corresponding relationship of a connection identifier and a next hop relay station ID; the node devices searching the connection identifier in a downlink Media Access Control Protocol Data Unit (MPDU) from the route database; if the route database has the connection identifier, according to the corresponding relationship, acquiring all the next hop relay station IDs corresponding to the connection identifier, then transmitting the downlink MPDU to all the acquired next hop relay station IDs till to a user terminal. The invention can realize data transmission of the multi-hop wireless communications system without changing the protocol structure of existing UE and core network. Furthermore, the invention also discloses the multi-hop wireless relay communications system as well as the base station and the relay station applied in the system.

Owner:HUAWEI TECH CO LTD

Multi-core network device message ordering method and system by interface

InactiveCN102891809BAvoid disorderPrecise scope of order preservationData switching networksMulticore cpuInterface model

The invention discloses an interface order-preserving method and system of messages of a multi-core network device. The interface order-preserving method comprises the following steps of: S1, after receiving current messages by CPUs of a multi-core CPU, obtaining import interface information of the current messages, carrying out import interface judgment on the current messages and grouping import interfaces of the messages; S2, sequencing the current messages by corresponding threads in corresponding import interface groups, processing the current messages; S3, after the current messages are processed, judging whether the former message of the same import interface is forwarded, if yes, forwarding the processed current messages, otherwise, and after waiting the former message is forwarded, forwarding the processed current messages. In addition, the invention also discloses an interface order-preserving system for realizing the interface order-preserving method. Through judging whether the former message of the same import interface is forwarded, the order preservation of the messages of the same import interface is realized, and the disorder when the messages are sent is prevented.

Owner:OPZOON TECH

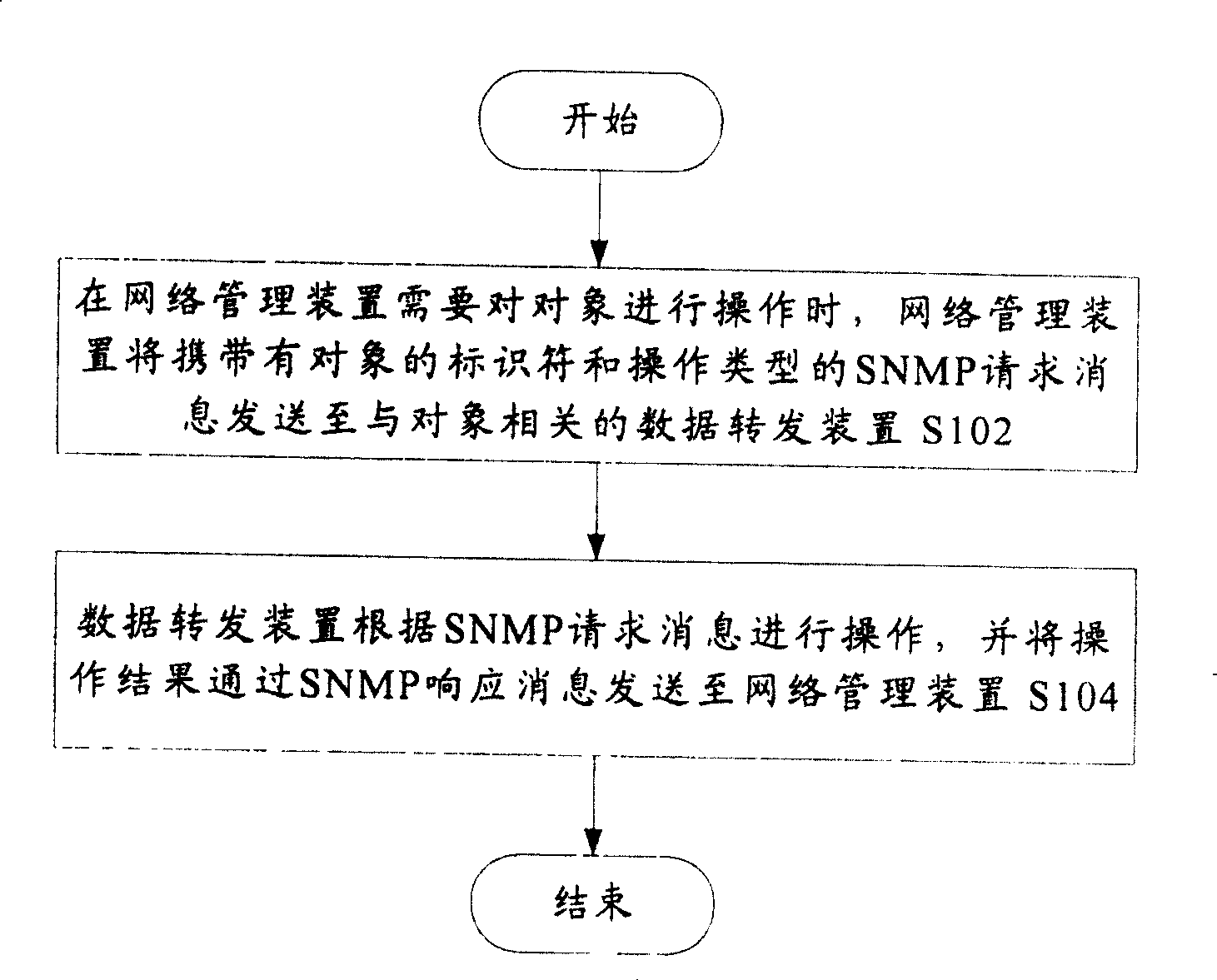

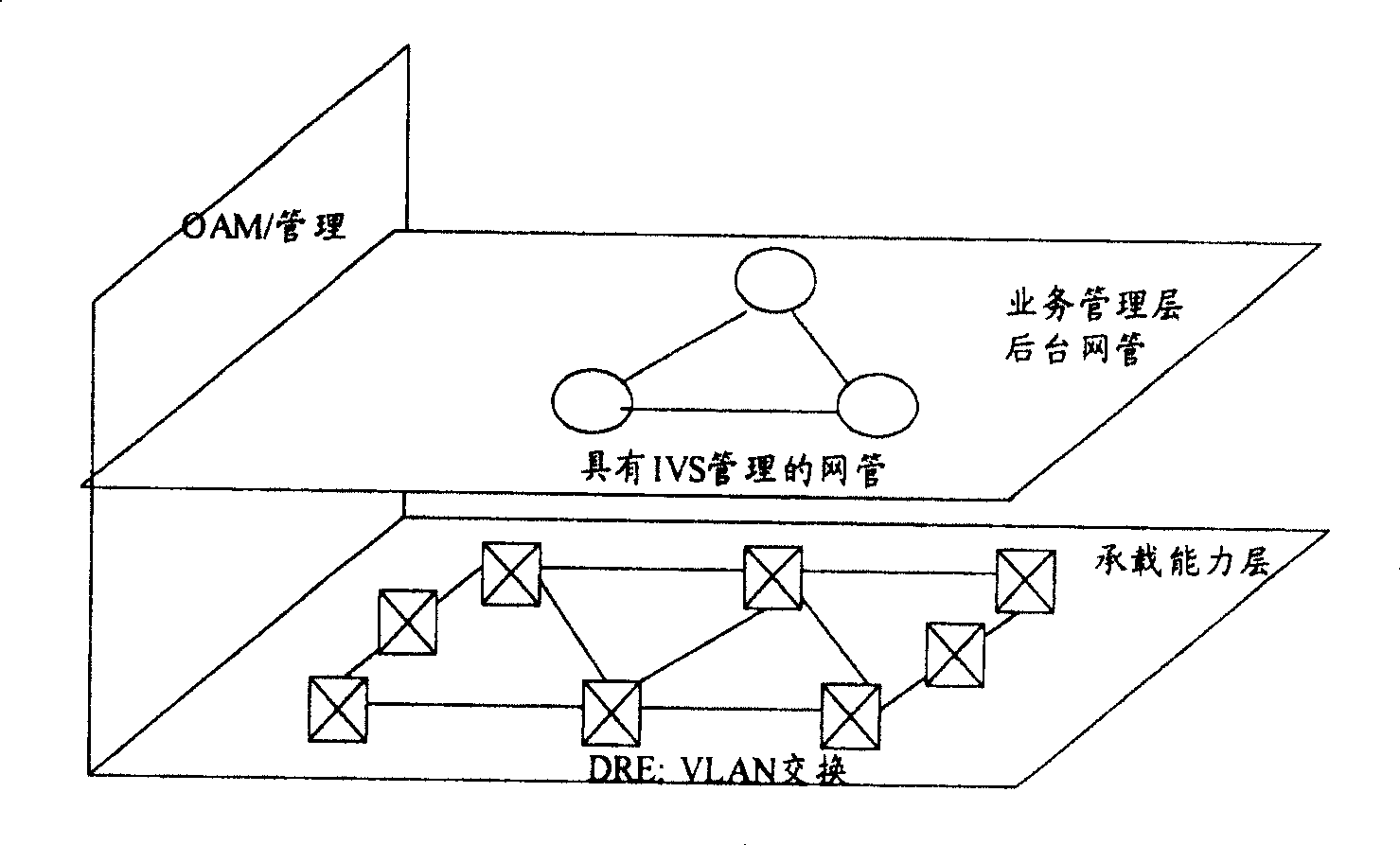

Intelligent virtual exchange method and system

InactiveCN100461703CLow retrofit costImprove bindingNetworks interconnectionNetwork managementDependability

The invention relates to an intelligent false exchange method and system. Wherein, at least one network manager distributes unique mark for the object needs to manage data transmitter; and the inventive method comprises that S102, when network manager operates the object, the manager sends the SNMP request message with the mark and operation type of object to the data transmitter; S104, data transmitter based on said request message operates and sends the operate result via SNMP response message to the network manager. The invention can improve the reliability.

Owner:ZTE CORP

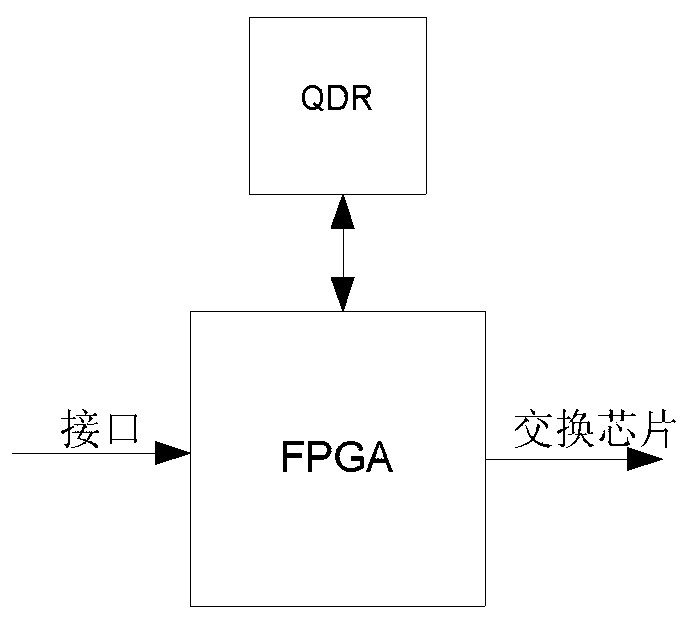

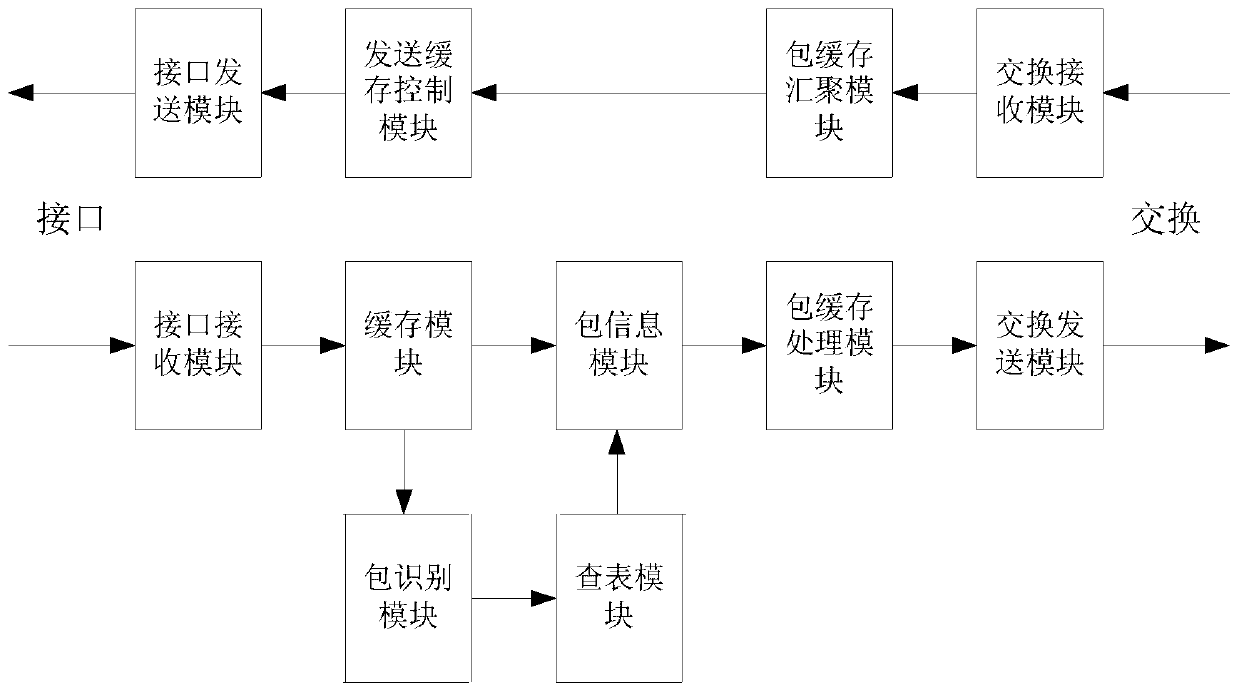

A data packet forwarding processing system and method

ActiveCN106656782BResolve incompatibilitiesSolve the problem of forwarding processingData switching networksTelecommunicationsCommunication device

The invention provides a data packet forwarding processing system which comprises a sending side unit and a receiving side unit. The input end of the sending side unit and the output end of the receiving side unit are connected respectively with a plurality of exchange chips. The output end of the sending side unit and the input end of the receiving side unit are connected respectively with line side interfaces. The data packets inputted by the exchange chips are converged through the sending side unit and are then transmitted to the line side interfaces. The data packets inputted by the line side interfaces are subjected to information identification through the receiving side unit and are then transmitted to the corresponding exchange chips. The invention also provides a data packet forwarding processing method. The invention effectively solves the problem faced by communication equipment that a large capacity interface cannot be compatible with a small capacity interface and at the same time, solves the problem with the data packet forwarding processing of the two. The system and the method of the invention can not only be simply realized at a low use cost, but are also faster and more convenient. The forwarding speed is also high; and the transmission speed is also effectively increased.

Owner:南京中新赛克科技有限责任公司

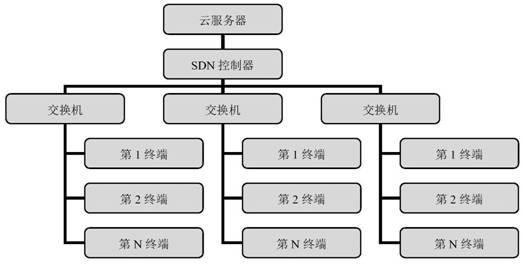

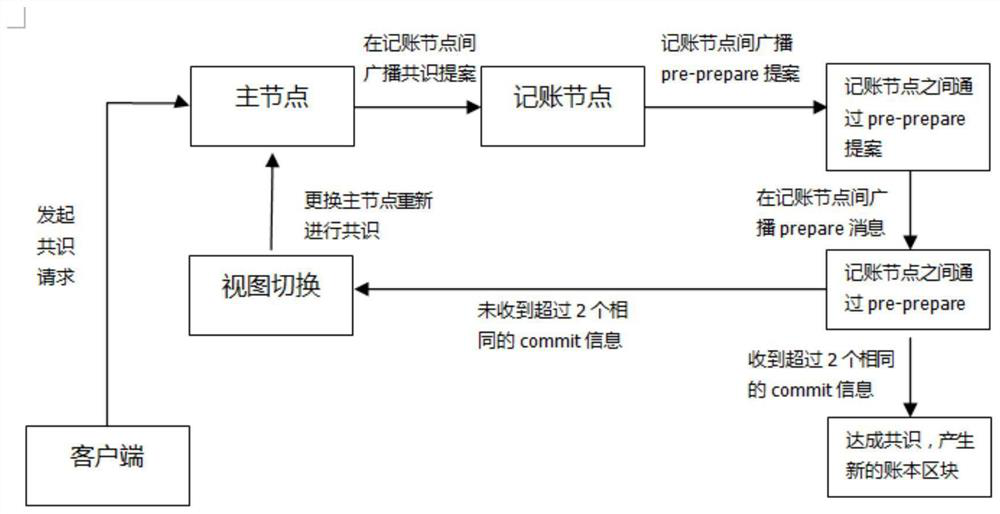

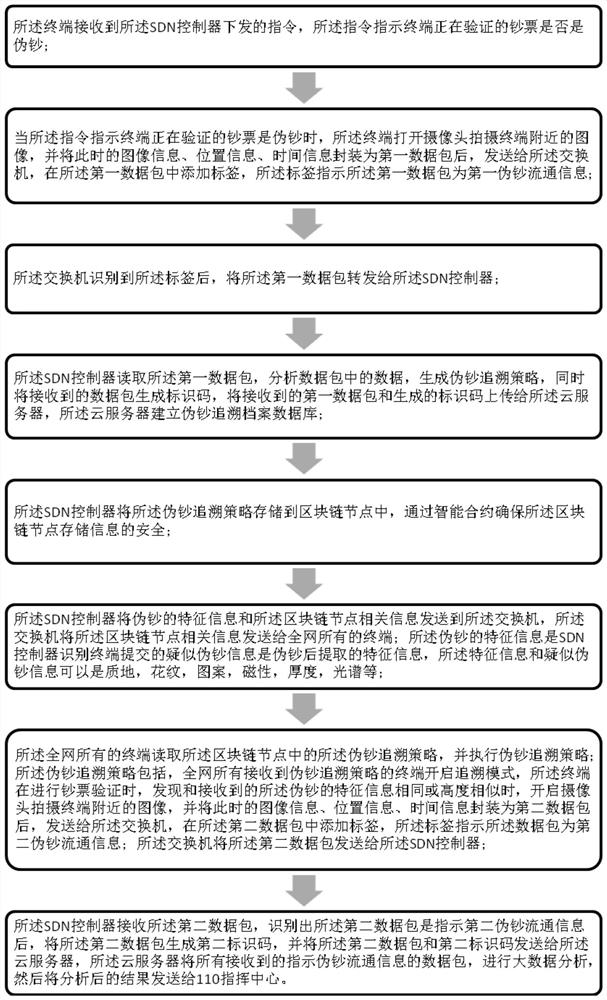

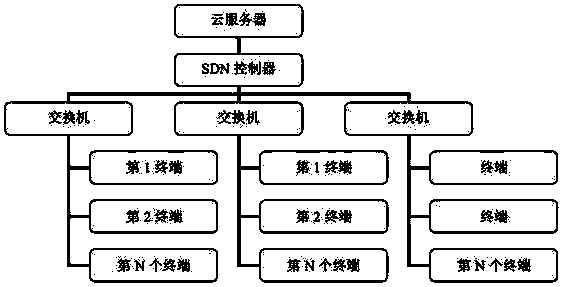

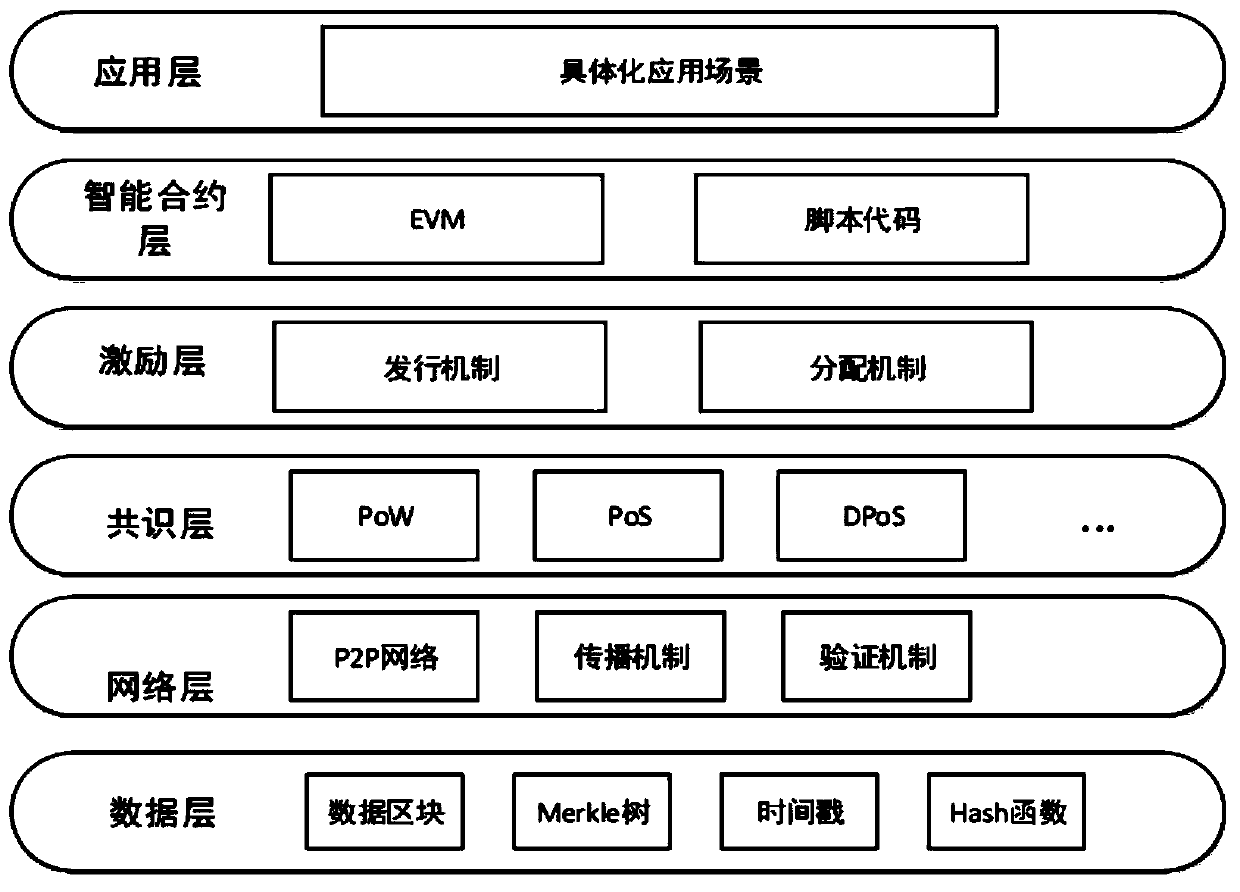

A blockchain-based transaction security identification method

InactiveCN111476656BReduce security risksFast forwardingTelevision system detailsKey distribution for secure communicationData packExchange network

The invention provides a block chain-based transaction security identification method. The terminal takes images related to counterfeit banknotes, forms the first data packet and sends it to the switch; the SDN controller reads the first data packet sent by the switch, analyzes and generates a counterfeit banknote traceability strategy, stores it in the blockchain node, and uploads the first data package To the cloud server; the cloud server establishes a counterfeit banknote traceability file database; the SDN controller sends the counterfeit banknote feature information and blockchain node related information to the switch, and the switch sends the blockchain node related information including the counterfeit banknote traceability strategy to all terminals in the entire network; The terminal implements counterfeit banknote traceability strategy. The invention reduces the failure rate of the terminal camera, improves the stability of the exchange network, and enhances the security of counterfeit banknote tracking strategies.

Owner:深圳市兴华融网络科技股份有限公司

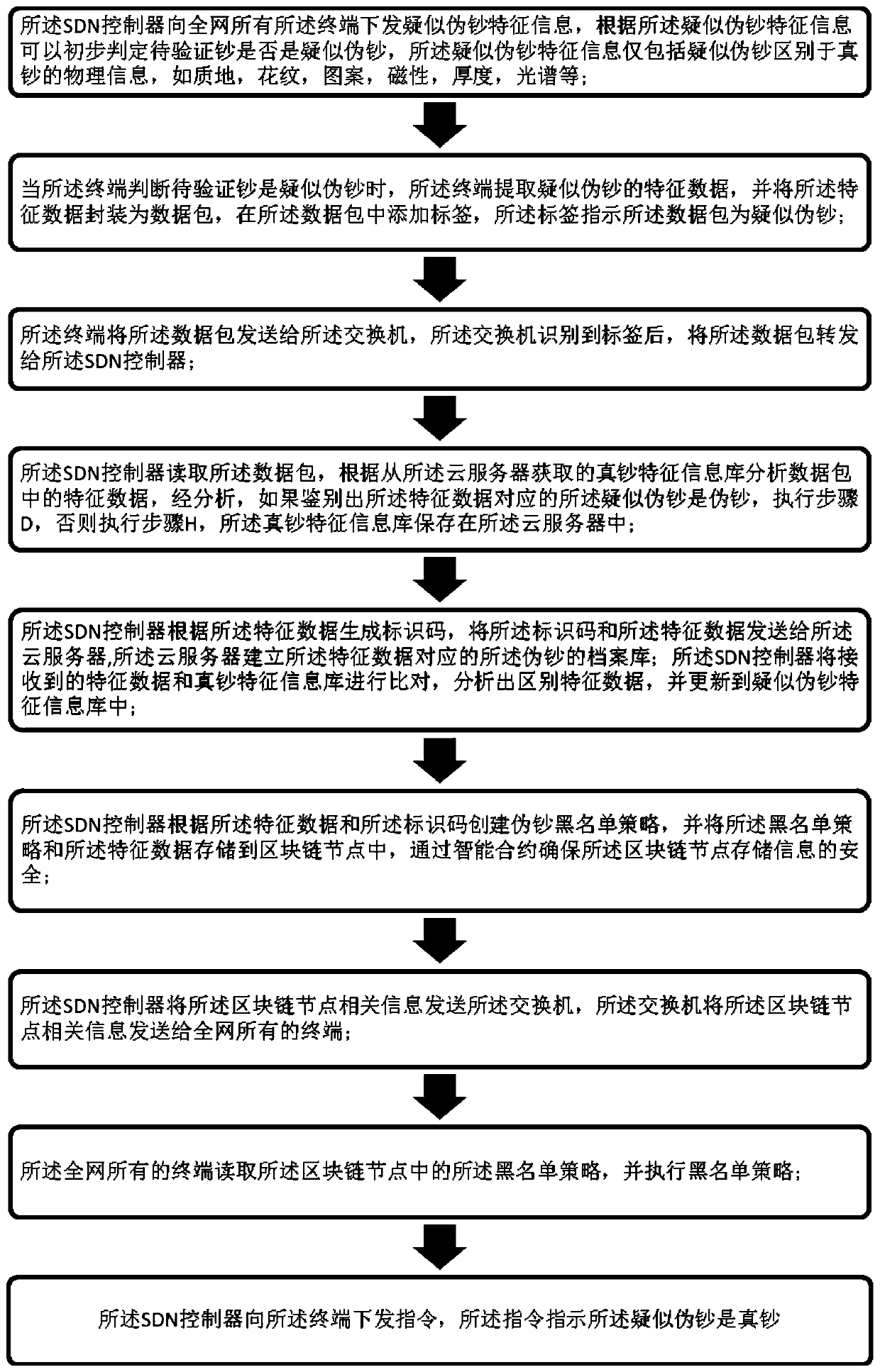

Counterfeit money identification method based on block chain and SDN

ActiveCN111369732AQuick identificationRelieve pressureDatabase updatingKey distribution for secure communicationInformation repositoryExchange network

The invention provides a counterfeit money identification method based on a blockchain and an SDN (Software Defined Network), and the method comprises the steps: a terminal being connected with a switcher, the switcher being connected with an SDN controller, the SDN controller being connected with a cloud server, and forming a counterfeit money identification system for counterfeit money identification. The method comprises: the terminal extracting and processing the feature data of the suspected counterfeit money and sending the feature data to the SDN controller; the SDN controller performing data analysis; when the banknote is judged to be counterfeit banknote, sending the generated identification code and the characteristic data to a cloud server, comparing the received suspected counterfeit money characteristic data with the true money characteristic information, analyzing distinguishing characteristic data, updating a suspected counterfeit money characteristic information base, creating a counterfeit money blacklist strategy, and storing the counterfeit money blacklist strategy and the characteristic data in a block chain node. Compared with a traditional currency detection method which performs feature comparison item by item through genuine currency and to-be-detected currency, the currency detection method is small in resource consumption and high in speed, feature information amount stored in the terminal is reduced, the security of the switching network is improved, and the risk of being stolen is reduced.

Owner:武汉楚天威豹金融服务有限公司

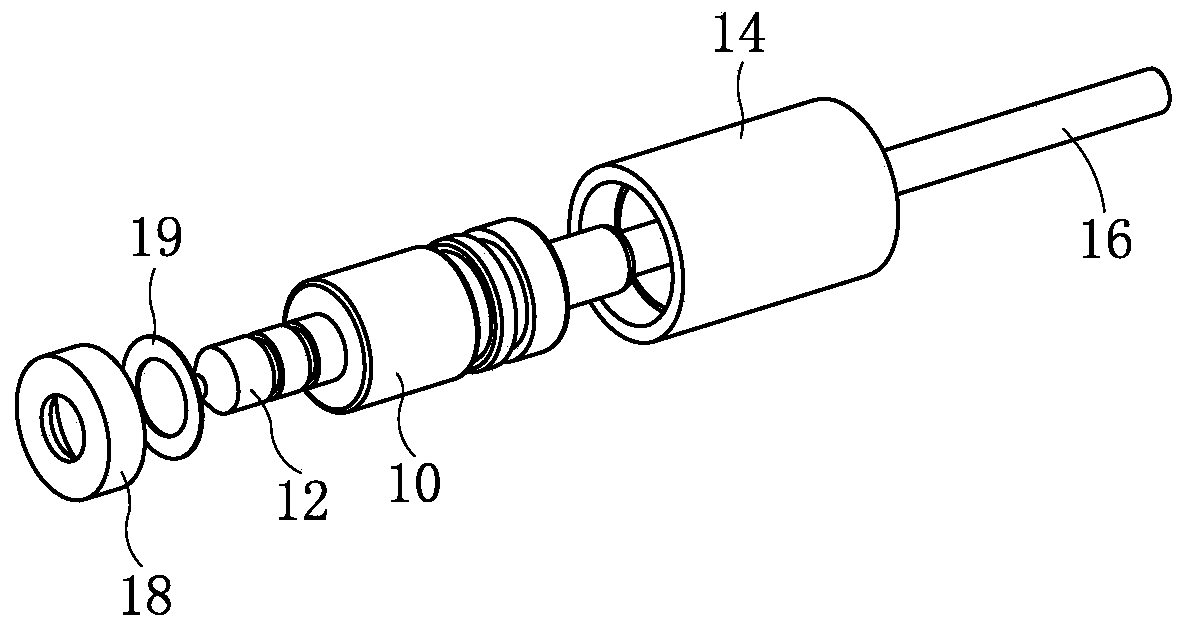

Medical cosmetology transdermal absorption enhancer containing natural plant essence and processing equipment of medical cosmetology transdermal absorption enhancer

InactiveCN114642990AEasy to processAvoid enteringRotating receptacle mixersTransportation and packagingElectric machineryBiochemistry

The invention discloses a natural plant essence medical cosmetology transdermal absorption enhancer and processing equipment thereof, and relates to the technical field of medical cosmetology, in particular to a vertical plate and an anti-collision pad, the vertical plate is internally provided with an auxiliary assembly for height adjustment, and the auxiliary assembly comprises a hydraulic air rod and an adapter block; an adapter block is installed at the bottom of the hydraulic air rod, and a fixing plate is installed on the surface of the bottom of the adapter block. According to the medical cosmetology transdermal absorption enhancer containing the natural plant essence and the processing equipment of the medical cosmetology transdermal absorption enhancer, through the design of a collection barrel in a concentration frame, a prepared preparation can be mixed in the collection barrel, and the concentration frame can be rotated through the design of a motor and a connecting shaft; therefore, the preparation placed in the concentration frame can be mixed, final forming of the accelerant is facilitated, and the design of the structure that the concentration barrel is wrapped by the concentration frame is beneficial for solving the problem of splashing during preparation evolution and mixing and ensuring rapid transfer of other preparations.

Owner:赵彬

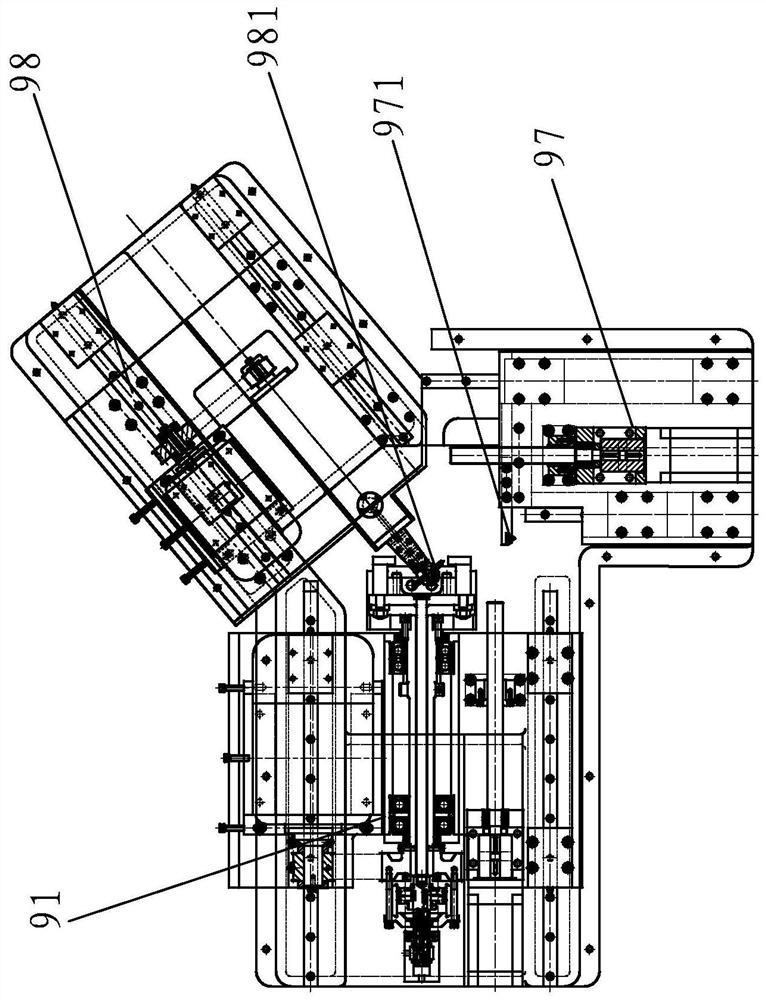

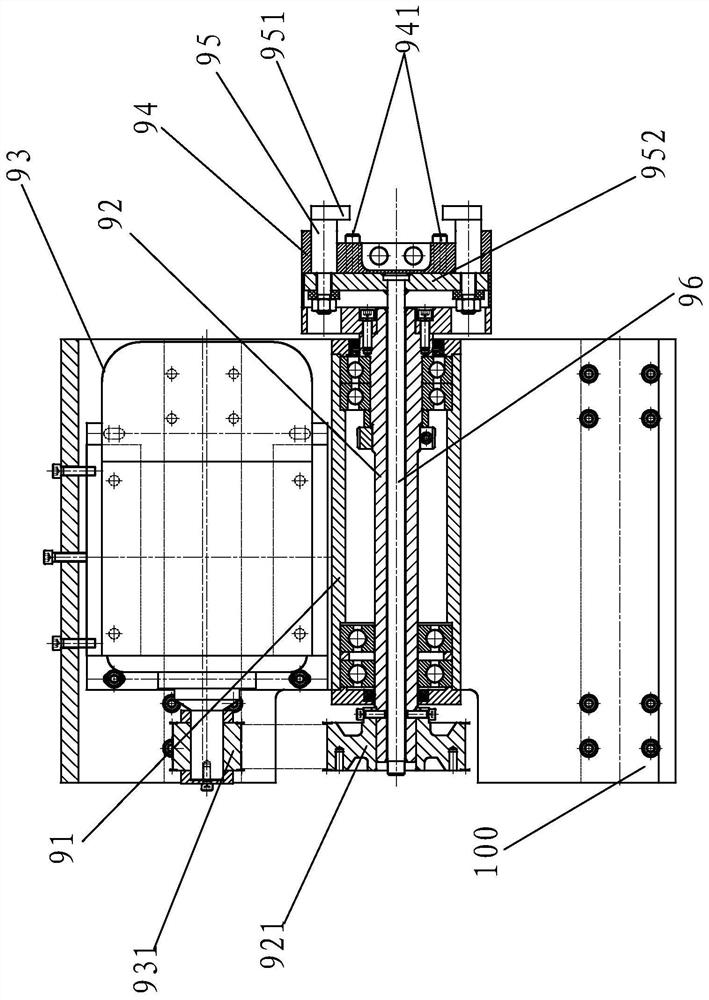

Numerical control bearing pedestal intelligent machining all-in-one machine

ActiveCN112475916AImprove work efficiencyImprove machining accuracyOther manufacturing equipments/toolsNumerical controlEngineering

The invention discloses a numerical control bearing pedestal intelligent machining all-in-one machine. The machine comprises a machining bin, a turning and drilling integrated device and a turning andgrinding integrated device, wherein the turning and drilling integrated device and the turning and grinding integrated device are mounted in the machining bin. The turning and drilling integrated device is provided with a mounting base and a first rotating base mounted in the mounting base, the first rotating base is fixedly provided with a first positioning base, and a transversely-moving rod ismounted in the first rotating base; and a turning tool device is arranged on the rear side of the right end of the mounting base, a drilling device is arranged outside the right side of the mountingbase, and a drilling and tapping device is arranged on the front side of the right end of the mounting base. The turning and grinding integrated device is provided with a turning and grinding base anda second rotating base located in the turning and grinding base, a second positioning base is mounted on the second rotating base, a turning tool base capable of horizontally moving left and right isarranged outside the right side of the turning and grinding base, a grinding wheel base inclining forwards and horizontally moving in the inclination direction is arranged on the rear side of the turning tool base, and a grinding wheel is arranged on the grinding wheel base. Compared with the prior art, turning, drilling, tapping and grinding are integrated, use is flexible, workpieces only needto be transferred once in the whole operation process, the working efficiency is high, and the machining precision is high.

Owner:泉州宇诺机械有限公司

Pre-filling and pre-sealing bottle making machine transferring mechanism and transferring method thereof

PendingCN112456769ASimple processShort pick-up and transfer timesGlass reforming apparatusMachineBottle

The invention discloses a pre-filling and pre-sealing bottle making machine transferring mechanism and a transferring method thereof.The pre-filling and pre-sealing bottle making machine transferringmechanism comprises a mechanical arm transfer assembly installed on a rack and used for transferring bottles, and the bottle taking position of a mechanical arm in the mechanical arm transfer assemblycorresponds to the position of an A-part discharging chuck of a bottle making machine; the bottle unloading position of the mechanical arm transfer assembly corresponds to the position of the B-partloading chuck; the transferring method of the pre-filling and pre-sealing bottle making machine comprises the following steps that a mechanical arm in the mechanical arm transfer assembly moves to a bottle taking position corresponding to an A-part discharging chuck of the bottle-making machine to take bottles, the mechanical arm transfer assembly clamps and conveys the bottles to a bottle discharging position corresponding to a B-part charging chuck, and the mechanical arm transfer assembly resets after discharging the bottles. The transfer time of semi-finished bottle bodies can be shortened, and the failure rate can be reduced. The mechanism is suitable for being arranged between a part A and a part B of the bottle making machine and used for transferring semi-finished bottle bodies ata discharging chuck of the part A to a charging chuck of the part B.

Owner:SHIJIAZHUANG LOYAL MACHINERY MFG

Ethernet network packet fast-forwarding realization method based on microwave facility network management system

InactiveCN101867493BRealize transmissionRealize monitoringData switching by path configurationSerial lineMicrowave

The invention relates to an ethernet network packet fast-forwarding realization method based on a microwave facility network management system; the method is realized based on the microwave facility network management system; the system comprises a management station and a plurality of microwave stations, the microwave station is composed of a microwave facility or a plurality of microwave facilities, the management station is connected with one microwave facility in one microwave station by a network line, a plurality of microwave facilities in one microwave station are connected by the network line, the adjacent microwave stations are connected mutually by a microwave link, self-definition is carried out to data format on the basis of simple network management protocol SNMP. In the invention, fast forwarding from the ethernet network packet structure to 64kbit / s serial line is realized, fast, stable and reliable forwarding requirements of a data packet are met, and the invention is a fast-forwarding realization method of the ethernet network packet in the serial link.

Owner:XIAN UNIV OF POSTS & TELECOMM

Implementation method of ipv6 tunnel on multi-core platform and packet forwarding method

ActiveCN103780469BFast forwardingImprove forwarding performanceNetworks interconnectionIPv6 packetHash chain

Owner:SHANGHAI BAUD DATA COMM

Multimedia stream transmission method and system

ActiveCN101917409BUses less kernel resourcesFast forwardingWireless network protocolsTransmissionComputer networkTransmission system

The invention relates to a multimedia stream transmission method. The method comprises the following steps of: obtaining a port number of a calling terminal multimedia stream transmitting port, the port number of a called terminal multimedia stream transmitting port, a first port number corresponding to the calling terminal multimedia stream transmitting port and a second port number corresponding to the called terminal multimedia stream port transmitting by using signaling sent by a calling terminal, the response made by the called terminal after the called terminal receives a signaling forwarded by a server and a port matching list set in the server; and forwarding the received multimedia stream between the first and second ports. The invention also relates to a multimedia stream transmission system. The multimedia stream transmission method and the multimedia stream transmission system of the invention have the advantages of relatively few occupied kernel resources and relatively high forwarding speed.

Owner:深圳黑洞光科技有限公司

Pre-filling and pre-sealing bottle making machine and bottle making method thereof

PendingCN112456767ASimple processShort pick-up and transfer timesGlass reforming apparatusCleaning using gasesMachine partsRobot hand

The invention discloses a pre-filling and pre-sealing bottle-making machine and a bottle-making method thereof. The pre-filling and pre-sealing bottle-making machine comprises a bottle-making machinepart A, a bottle-making machine part B and a transferring mechanism arranged between the bottle-making machine part A and the bottle-making machine part B; bottle-making machine part A and the bottle-making machine part B are fixed on a bottle making machine frame. The transferring mechanism comprises a mechanical arm transferring assembly installed on a machine frame and used for transferring bottle bodies; the bottle taking position of a mechanical arm in the mechanical arm transferring assembly corresponds to the position of an A-part discharging chuck of the bottle making machine, and thebottle discharging position of the mechanical arm transferring assembly corresponds to the position of a B-part charging chuck of a B-part bottle taking station. The bottle-making method of the pre-filling and pre-sealing bottle-making machine comprises the following steps that the bottle-making machine part A machines a bottle body, the transferring mechanism transfers the bottle body, and the bottle-making machine part B machines the bottle body. The transfer time of semi-finished bottle bodies can be shortened, and the failure rate can be reduced. The invention is suitable for the pre-filling and sealing bottle-making machine to produce the pre-filling and sealing glass bottle body.

Owner:SHIJIAZHUANG LOYAL MACHINERY MFG

Positioning orthopedic equipment

ActiveCN107008773BImprove consistencyAchieve shapingMetal-working feeding devicesPositioning devicesEngineering

The invention discloses a locating and shaping device and relates to the technical field of product shaping equipment. The locating and shaping device comprises an attraction locating device and a shaping device. The attraction locating device comprises an attraction locating assembly capable of longitudinally moving. The attraction locating assembly comprises multiple clamping blocks capable of transversely moving. The clamping blocks can provide transverse clamping force for products. The shaping device comprises an upper shaping device body and a lower shaping device body, wherein the upper shaping device body and the lower shaping device are oppositely arranged on the upper side and the lower side of an installation base plate correspondingly. The portion, corresponding to the shaping device, of the installation base plate is provided with a vertically-through hole. The upper shaping device body and the lower shaping device body each comprise a shaping plate capable of moving up and down. Each shaping plate is provided with shaping grooves adaptable to the structure of components to be shaped. The locating and shaping device can achieve accurate locating of the product, the shaped product components are good in consistency, the shaping efficiency is high, the yield of the products can be improved, automatic product is facilitated, and the production cost of an enterprise is reduced.

Owner:GOERTEK INC

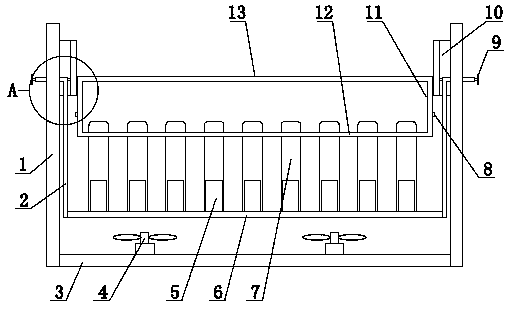

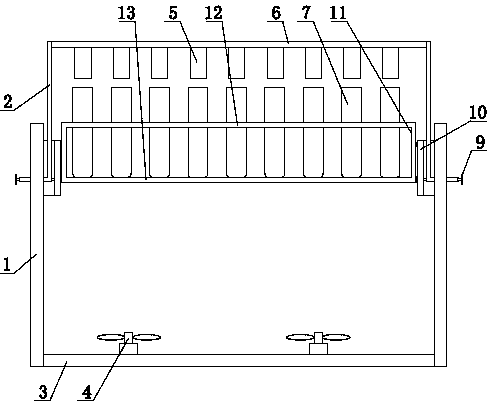

Test tube drying device and method for student test

InactiveCN109237881AFast dryingImprove efficiencyDrying solid materialsDrying machines with local agitationPulp and paper industryTest tube

The invention discloses a test tube drying device and method for a student test. The device comprises a bracket base, a drying frame and a collection frame, wherein the drying frame and the collectionframe are arranged on the bracket base, the drying frame is provided with multiple first test tube supporting structures enabling test tubes to be fastened inversely, and the collection frame is provided with multiple second test tube supporting structures enabling the test tubes to be inserted into. The test tube drying device and method for the student test have the advantages that the drying method uses the above the test tube drying device for the student test, the drying device is provided with the drying frame and the collection frame so that the test tubes can be dried under the inverted state, the drying speed is quick, the test tubes can be quickly transferred to the collection frame in batch after being dried, the collection frame can be bent down from the bracket base, the timecan be concentrated to dry the test tubes, every batch of the dried test tubes can be collected by one collection frame, so that the drying speed of the test tubes is quick, and the efficiency is high.

Owner:济南毕昇信息科技有限公司

Audit control method and system for serial data flow

ActiveCN104753726BImprove network throughputHigh-speed data forwardingData switching networksInformation controlData stream

Owner:SURFILTER NETWORK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com