Pre-filling and pre-sealing bottle making machine transferring mechanism and transferring method thereof

A bottle making machine, pre-filling and sealing technology, applied in the direction of manufacturing tools, glass manufacturing equipment, glass reshaping, etc., can solve the problems of high precision machining, high matching degree, difficult production and other problems, and achieve the goal of manufacturing The effect of high bottle quality precision, high product quality and fast transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

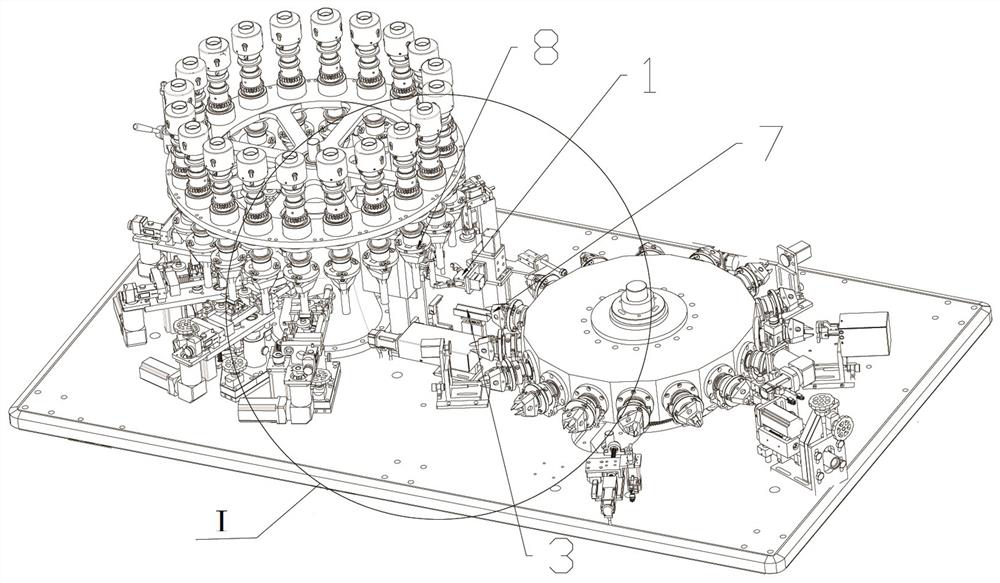

[0039] Example 1 A transfer mechanism and transfer method of a pre-filling bottle making machine

[0040] This embodiment is an improvement to the transfer mechanism originally located between Part A and Part B of the bottle making machine, that is, the manipulator in the transfer assembly of the manipulator is used to directly pick up the bottle from the 8 unloading chucks of Part A of the bottle making machine, and the manipulator The transfer assembly completes the transfer of the semi-finished bottle to the charging chuck 7 of part B.

[0041] The transfer assembly of the manipulator is installed on the frame. The bottle picking position of the manipulator in the transfer assembly corresponds to the position of the unloading chuck 8 of part A of the bottle making machine, and the position of unloading the bottle of the transfer assembly of the manipulator corresponds to the position of the loading chuck 7 of part B. correspond. That is, when the bottle body is transferred...

Embodiment 2

[0044] Example 2 A transfer mechanism and transfer method of a pre-filling bottle making machine

[0045] The difference between this embodiment and the transfer mechanism of the pre-filling and sealing bottle making machine in Embodiment 1 is that the manipulator transfer assembly in this embodiment is at least two manipulators, and the two manipulators cooperate with each other to transfer the bottle body from the discharge chuck 8 of part A to charging chuck 7 of part B. That is, the first manipulator is installed on the frame close to the discharge chuck 8 of part A, the position of taking the bottle of the first manipulator corresponds to the position of the discharge chuck 8 of part A, and the position of unloading the bottle of the first manipulator corresponds to the position of the discharge chuck 8 of part A. The bottle taking position of the second manipulator is corresponding; the second manipulator is installed on the frame close to the B part charging chuck 7, an...

Embodiment 3

[0052] Example 3 A transfer mechanism and transfer method of a pre-filling bottle making machine

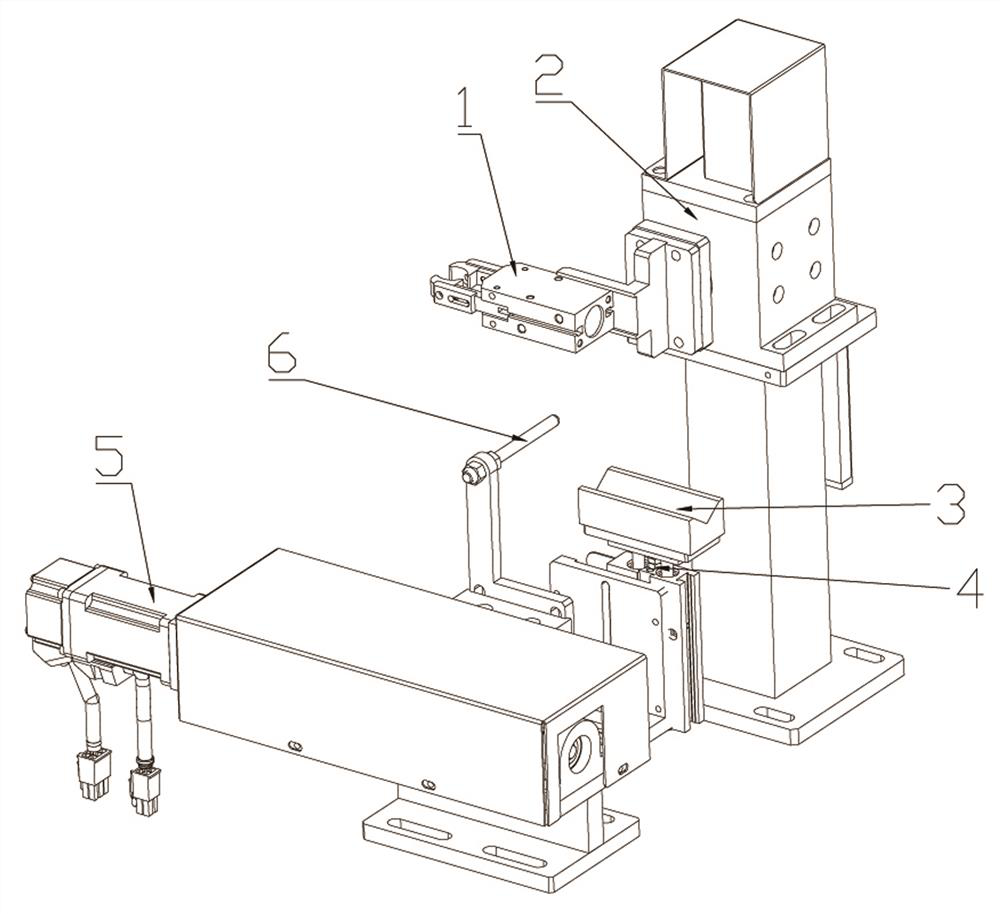

[0053] The difference between this embodiment and the transfer mechanism of the pre-filling bottle-making machine in Embodiment 1 to Embodiment 2 is that the transfer assembly of the manipulator includes a manipulator, a bottle holder and a bottle pusher.

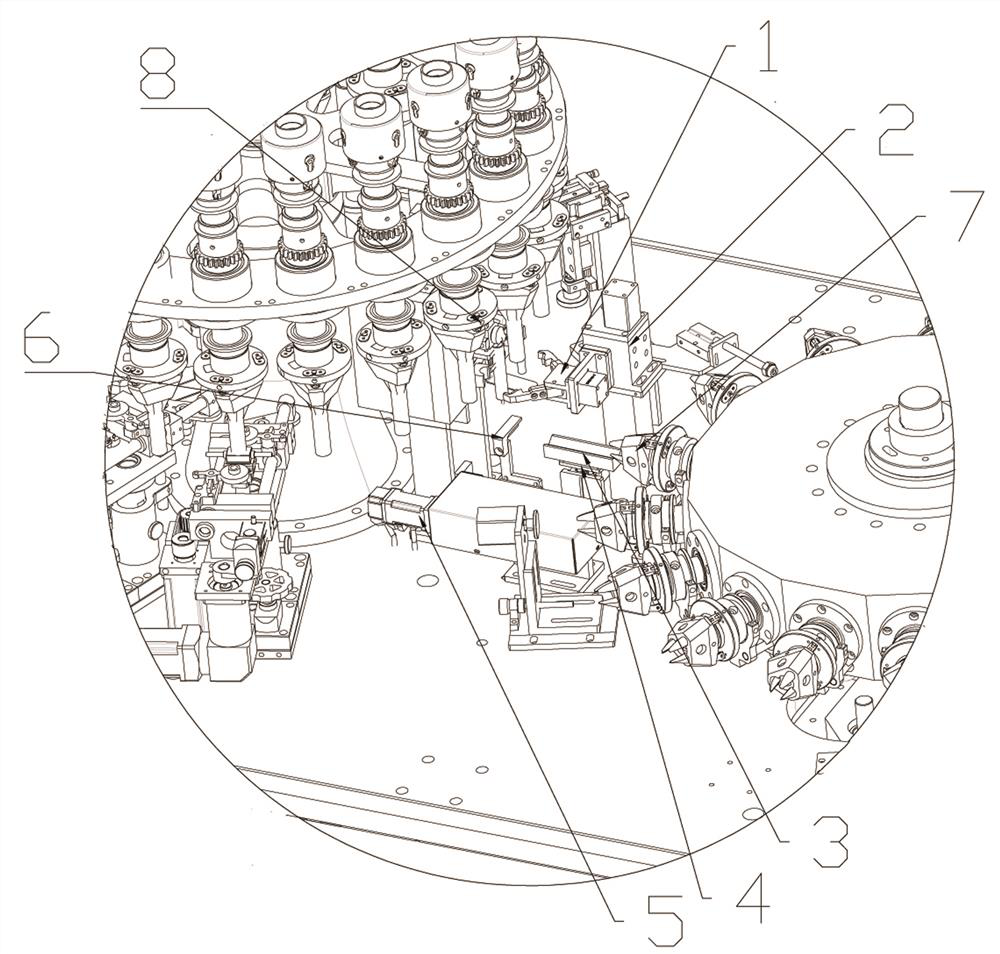

[0054] Such as Figure 1 to Figure 3 As shown, the bottle picking position of the manipulator corresponds to the position of the unloading chuck 8 of part A of the bottle making machine, the bottle unloading position of the manipulator corresponds to the bottle receiving position of the bottle holder, and the bottle feeding position of the bottle holder corresponds to the bottle pusher The position of pushing the bottle and the position of the charging chuck 7 of part B correspond. The composition of each part is described as follows:

[0055] The manipulator is used to remove the semi-finished bottle body at the discharge c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com