Method and equipment for customizing batching and color-matching daily chemical product

A product and equipment technology, applied in the field of daily chemical products that can customize ingredients and color matching according to consumers' own preferences, can solve the problems of inability to meet personalization, low precision, and inability to match products, etc., to achieve distinctive characteristics of the times and practicality Sexuality, a wide range of individual needs, and a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] A method for customizing daily chemical products with ingredients and color matching, comprising the following steps:

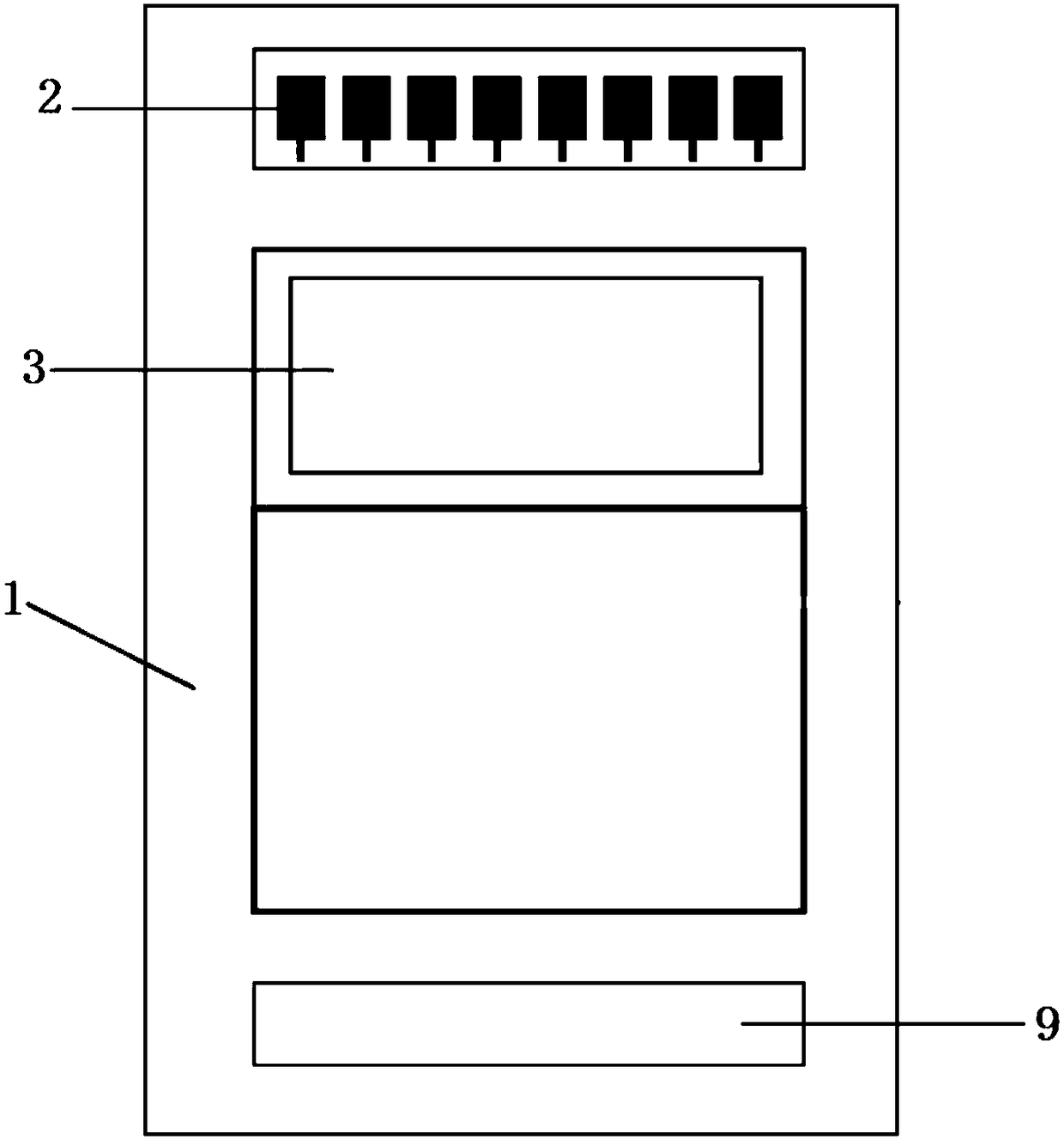

[0045] A color-matching machine display screen 3 or app is provided with a color-coded input device;

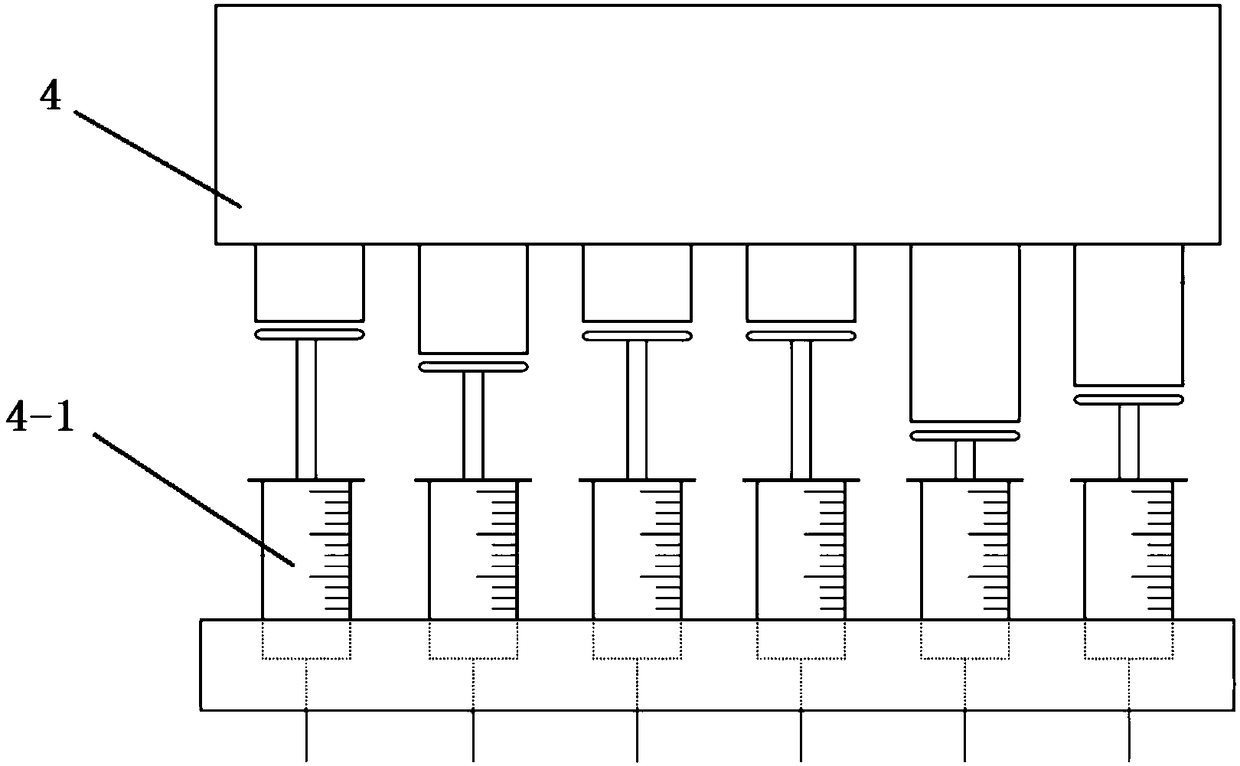

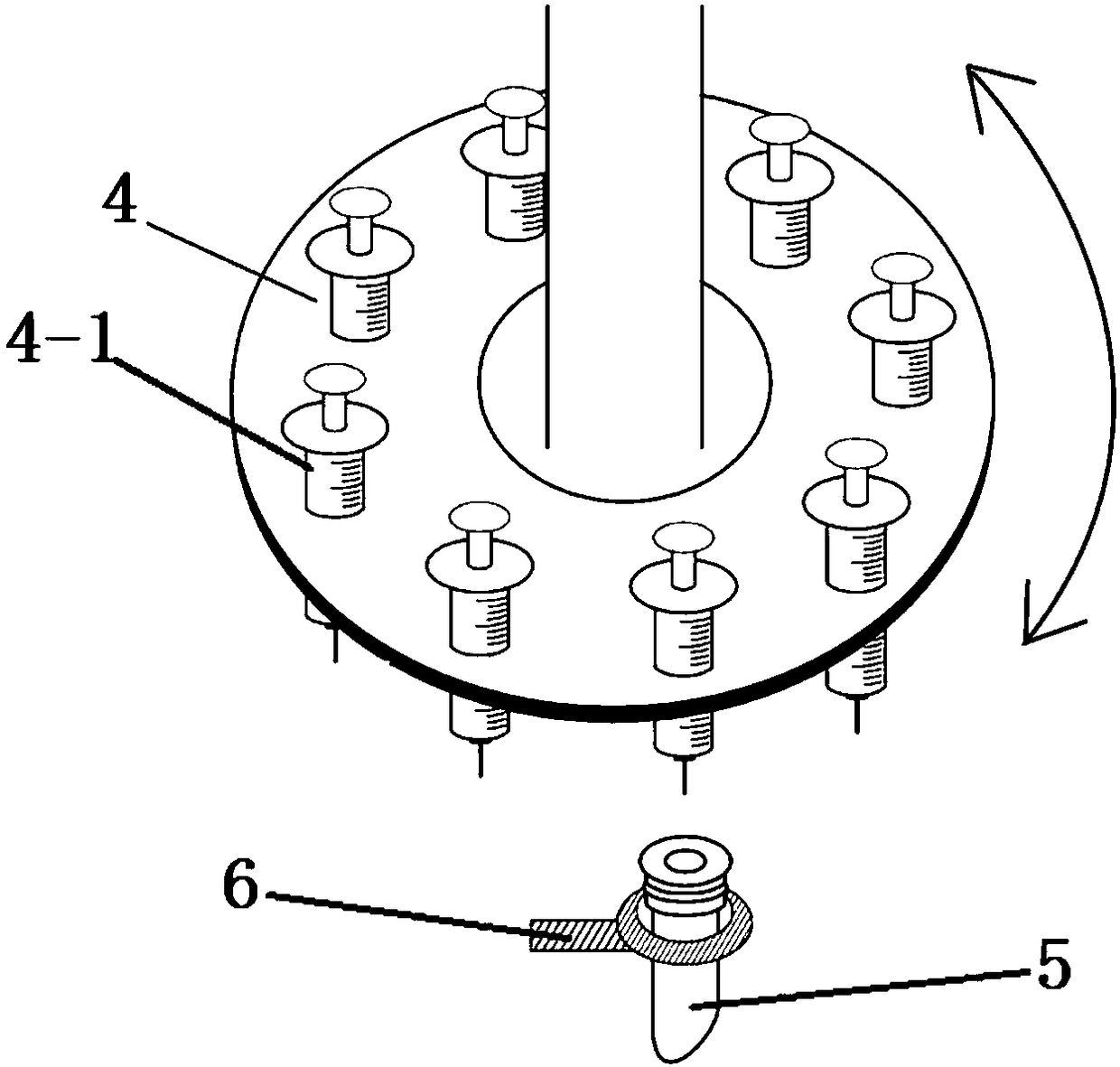

[0046] B colorless aggregate is stored in the batching output device 4 in a solid or semi-solid or liquid state, and the basic color material is stored in the batching output device 4 in a liquid color paste mode;

[0047] C starts the computer program extrusion batching output device 4 set in A step, and the set colorless aggregate and basic colorant dosage are squeezed into the mold 5 and mixed;

[0048] D mixed colorless aggregate and basic color material are melted into liquid by heating container 7, and stirred by ultrasonic vibration;

[0049] After stirring evenly, the mold 5 is put into the cooling container 8 and shaped into a sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com