Pre-filling and pre-sealing bottle making machine and bottle making method thereof

A bottle making machine, pre-filling and sealing technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve the processing requirements of high precision parts, high matching requirements, and manufacturing difficulties and other problems, to achieve the effect of high quality bottle making accuracy, high product quality, and fast transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

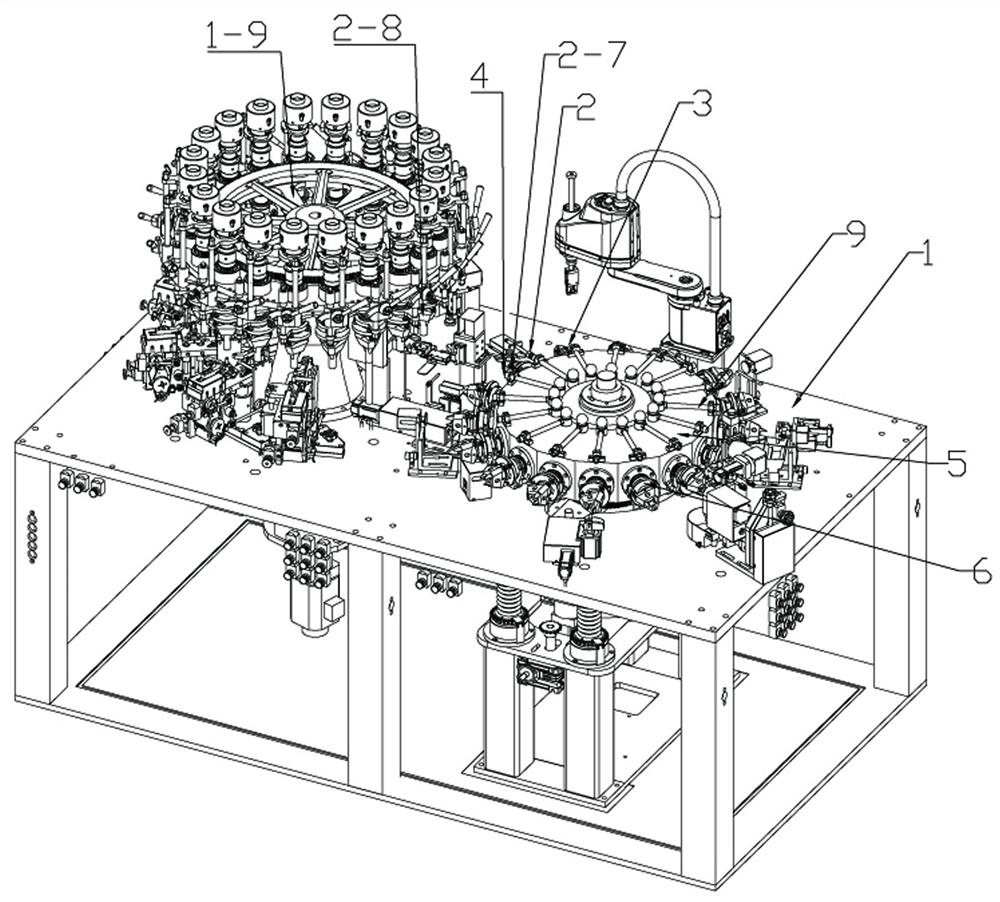

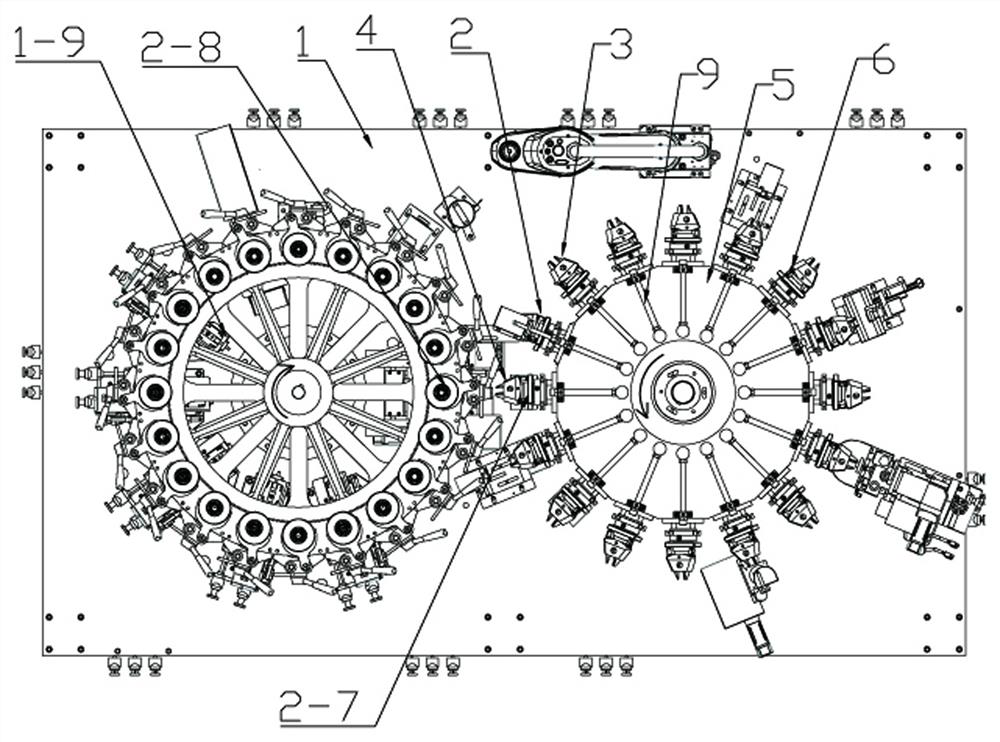

[0057] Embodiment 1 A kind of pre-filling and sealing bottle making machine

[0058] Such as Figure 1 to Figure 8 As shown, the present embodiment includes bottle making machine A parts 1-9 and B parts which are all fixedly mounted on the bottle making machine frame 1 and a transfer mechanism placed between the bottle making machine A parts 1-9 and B parts.

[0059] 1. Part A of bottle making machine 1-9

[0060] Part A 1-9 of the bottle making machine is used to process glass tubes to form semi-finished pre-filled bottles. Part A 1-9 of the bottle making machine adopts the structure of part A 1-9 of the bottle making machine in the prior art, that is, part A 1-9 of the bottle making machine includes a chuck disc of part A driven by a motor, and the ring is uniformly assembled in the circumferential direction. Multiple A-section chucks on the A-section chuck plate and multiple A-section bottle processing mechanisms. Because the bottleneck extrusion mechanism in the bottle-...

Embodiment 2

[0085] Embodiment 2 A kind of bottle making method of pre-filling and sealing bottle making machine

[0086] This embodiment utilizes the pre-filling and sealing bottle-making machine in embodiment 1 to realize, under the control of the pre-filling and sealing bottle-making machine controller, comprises the following steps:

[0087] S1. Processing of bottle body in part 1-9 of bottle making machine:

[0088] The motor drives the chuck disc of part A to rotate. After the chuck of part A of the bottle making machine passes through the corresponding processing mechanism of part A to fix and cut the glass tube, the motor drives the chuck disc of part A to rotate to the position corresponding to the extrusion mechanism of the bottle mouth. The bottle mouth extruding station carries out the process of extruding the bottle mouth, and the steps of using the bottle mouth extrusion mechanism to squeeze the bottle mouth are as follows:

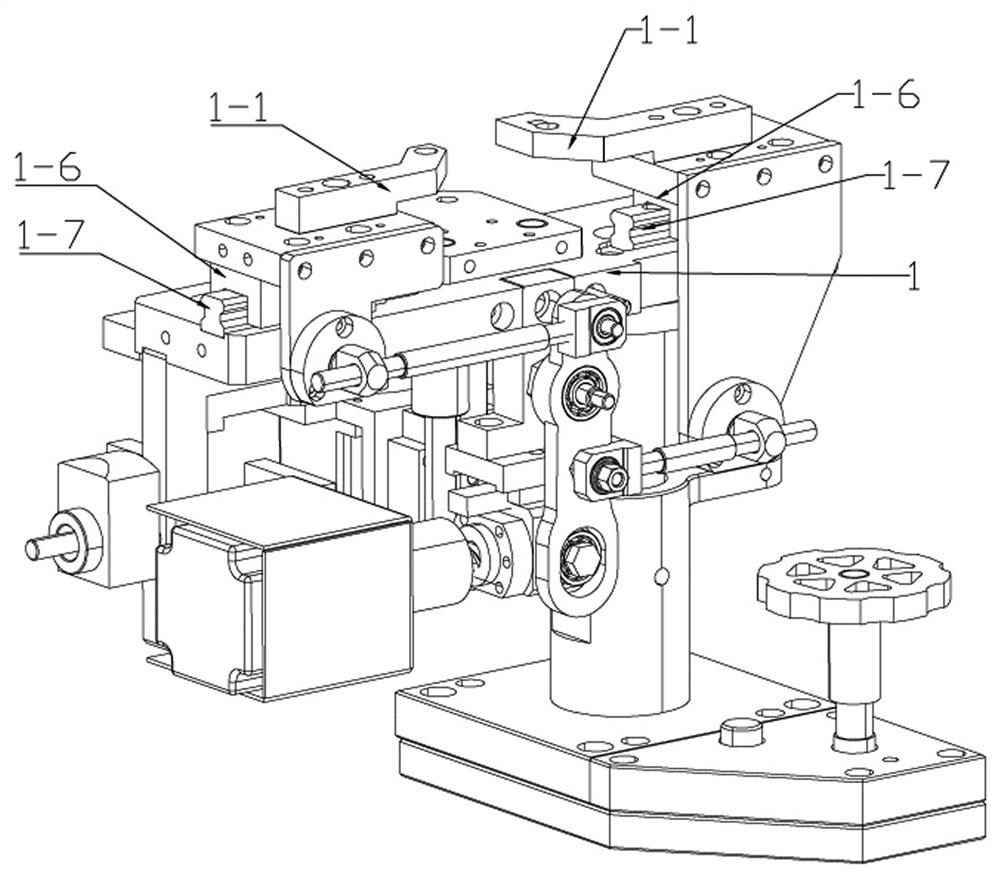

[0089] S11. The mold opening and closing drive me...

Embodiment 3

[0112] Embodiment 3 A kind of pre-filling and sealing bottle making machine and its bottle making method

[0113] This embodiment is an improvement to the flexible extrusion structure of the bottle mouth after the bottle mouth mold is closed in Part A 1-9 of the bottle making machine. The mold opening and closing drive mechanism drives the flexible extrusion assembly to generate the drive to drive the left and right half molds After the left and right half molds are closed, the ball slide 1-6 and support plate 1-10 in the sliding assembly continue to slide along the slider 7 under the action of the driving force, so that the compression spring 1-5 shrinks and deforms on the left and right half molds The elastic force is formed, so that the driving force and the elastic force squeeze the left and right half molds to form the clamping force of the flexible extrusion bottle mouth, and provide flexible extrusion force for the left and right half mold extrusion bottle mouths, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com