Numerical control bearing pedestal intelligent machining all-in-one machine

A technology of intelligent processing and bearing housing, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of low work efficiency and difficulty in guaranteeing processing accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

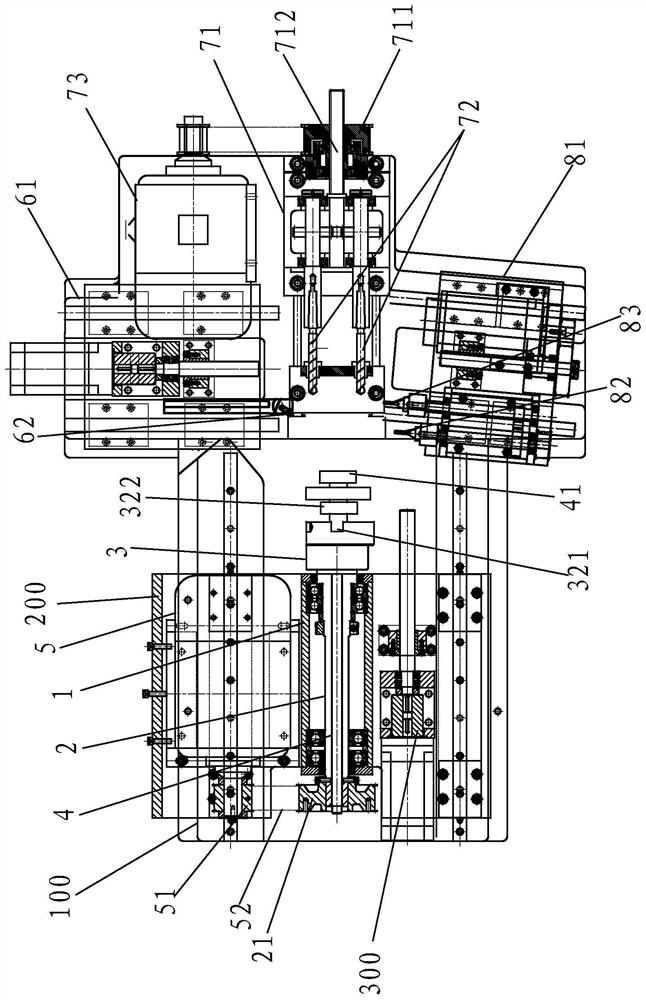

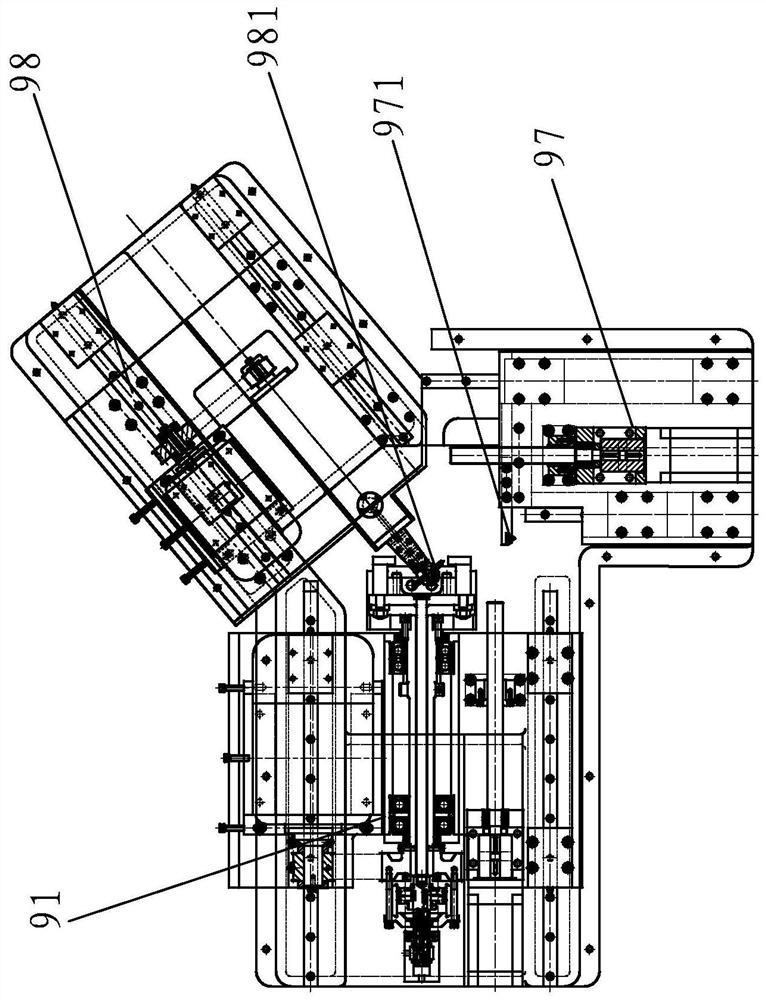

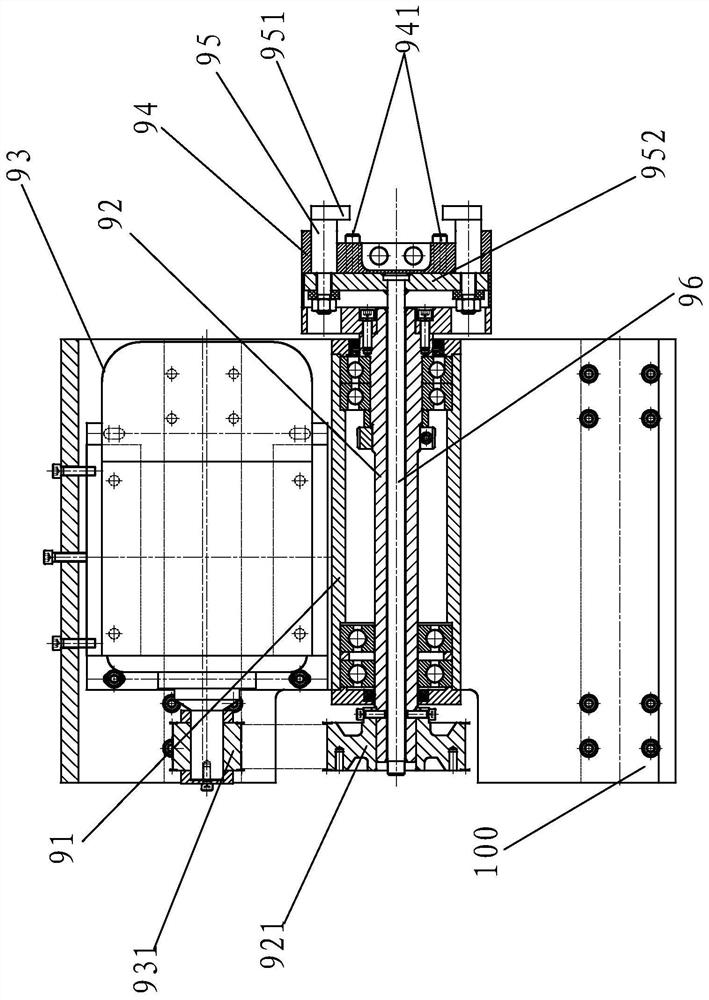

[0024] A kind of numerically controlled bearing housing intelligent processing all-in-one machine of the present invention, such as Figure 1-4 As shown, it includes a processing chamber (not shown in the figure) and a turning-drilling integrated device and a turning-milling integrated device installed in the processing chamber,

[0025] The processing chamber is a hollow seat body, which is a rectangular chamber body. There is a window on the top surface of the processing chamber, and a sliding door for closing the window is installed on the processing chamber. The cooperation between the sliding door and the window is the prior art. I won't repeat it here. Utilizing the sliding door can conveniently close the processing chamber during processing, so as to avoid splashing waste chips generated during processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com