Tube storage and transport device for textile machine producing cross-wound packages

A technology for cross-winding bobbins and conveying equipment. It is used in textile and paper making, conveyors, conveyor objects, etc. It can solve problems such as frequent maintenance and complex structural design, achieve clock time optimization, ensure uninterrupted operation, and reduce errors. The effect of the source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

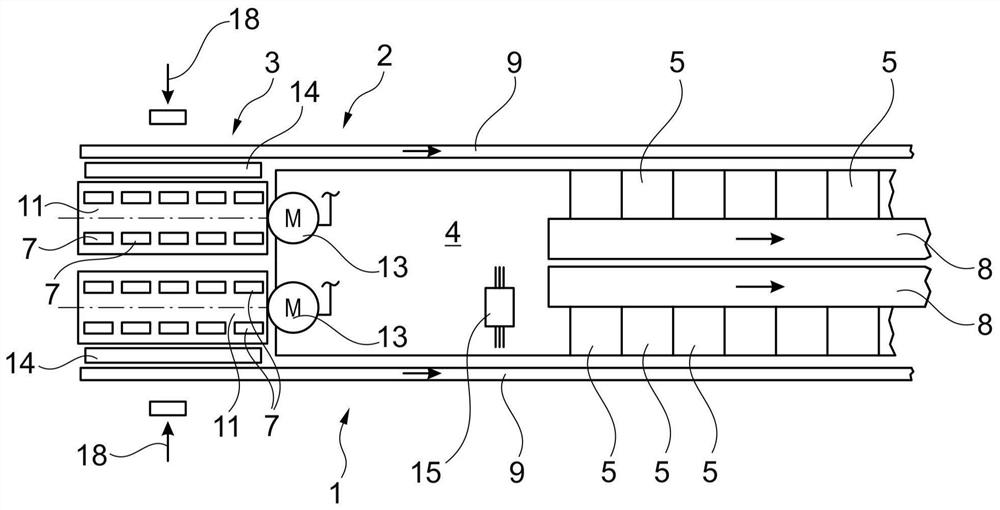

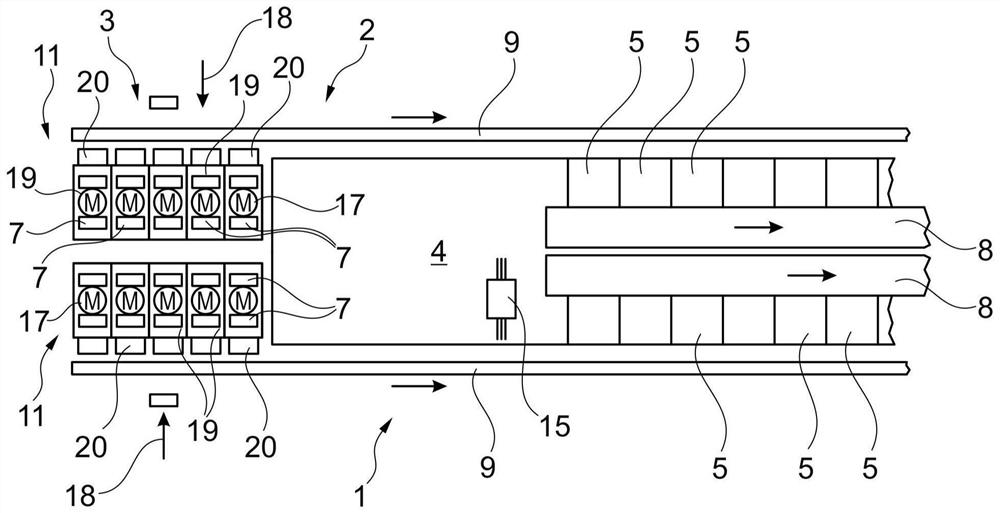

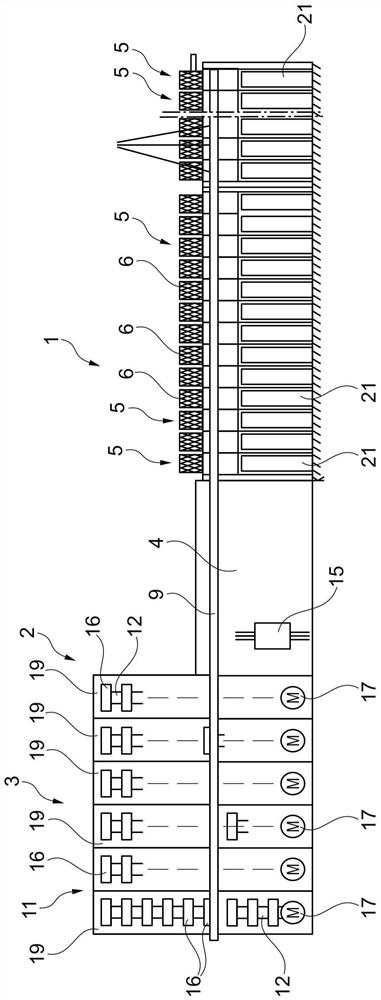

[0066] figure 1 Shown is a first embodiment of a bobbin magazine 3 of a bobbin storage and conveying device generally designated with the reference number 2, which is arranged in the machine end region of a textile machine producing cross-wound bobbins. The textile machine for producing cross-wound bobbins is designed as an open-end rotor spinning machine 1, as is known, with a plurality of workstations 5 between its end frames 4, which are arranged at the end of the open-end rotor spinning machine 1. Two longitudinal machine sides, such as figure 1 shown. As is also known and therefore not shown in more detail, the workstations 5 each have a spinning device and a downstream winding device, which are supplied by a number of service units (not shown) during the spinning / winding operation, The service unit is for example displaceably mounted on the track structure. When working on one of the workstations, a service unit (usually a "change and cleaning cart") steps in. Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com