Intelligent quick lofting method suitable for drilling and blasting

A fast and intelligent technology, applied in blasting and other directions, can solve problems such as unsatisfactory blasting effect, hidden safety hazards, lengthy procedures, etc., and achieve the effect of reliable stakeout and positioning results, intelligent stakeout process, and automation of stakeout process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

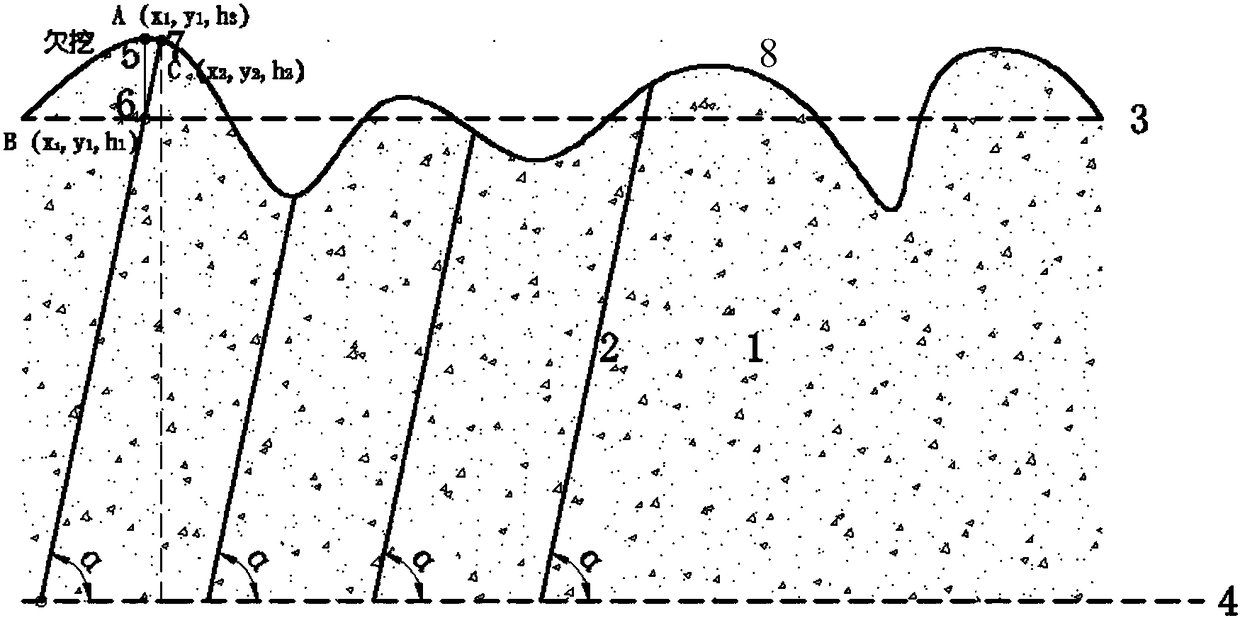

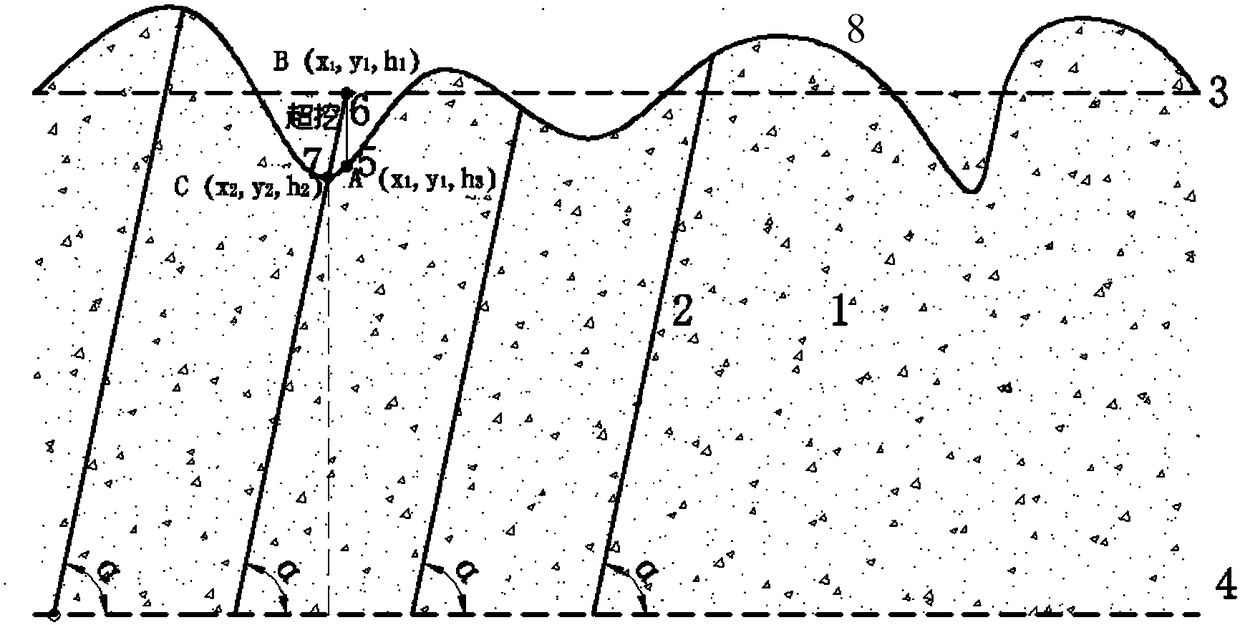

[0025] In the following, the present invention will be further introduced in conjunction with specific implementation methods. In the embodiment, the undercut of the contour surface is taken as an example. Blasting is carried out on a certain slope, the excavation height of the slope is 10m, the inclination angle of blastholes is 60°, and the row spacing between blastholes is 3*3m. An uneven working face was formed after a bench blasting, and the design elevation of the current bench excavation is EL.1000m.

[0026] 1. The coordinates of initial design stakeout point B (attached figure 1 Indicated by 6) through the preparation of the corresponding data format, transmission and storage to the total station.

[0027] 2. Embed the mathematical program of automatic conversion into the total station.

[0028] According to the coordinates of the initial design stakeout point B and the inclination angle of the blast hole, the actual coordinates corresponding to the drilling at any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com