Multifunctional shaft part detection device

A technology for detection devices and parts, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of unable to measure the radius value of the circle, unable to check the full runout of the cylinder, and limited measurement range, so as to facilitate assembly, Convenient axial adjustment and wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

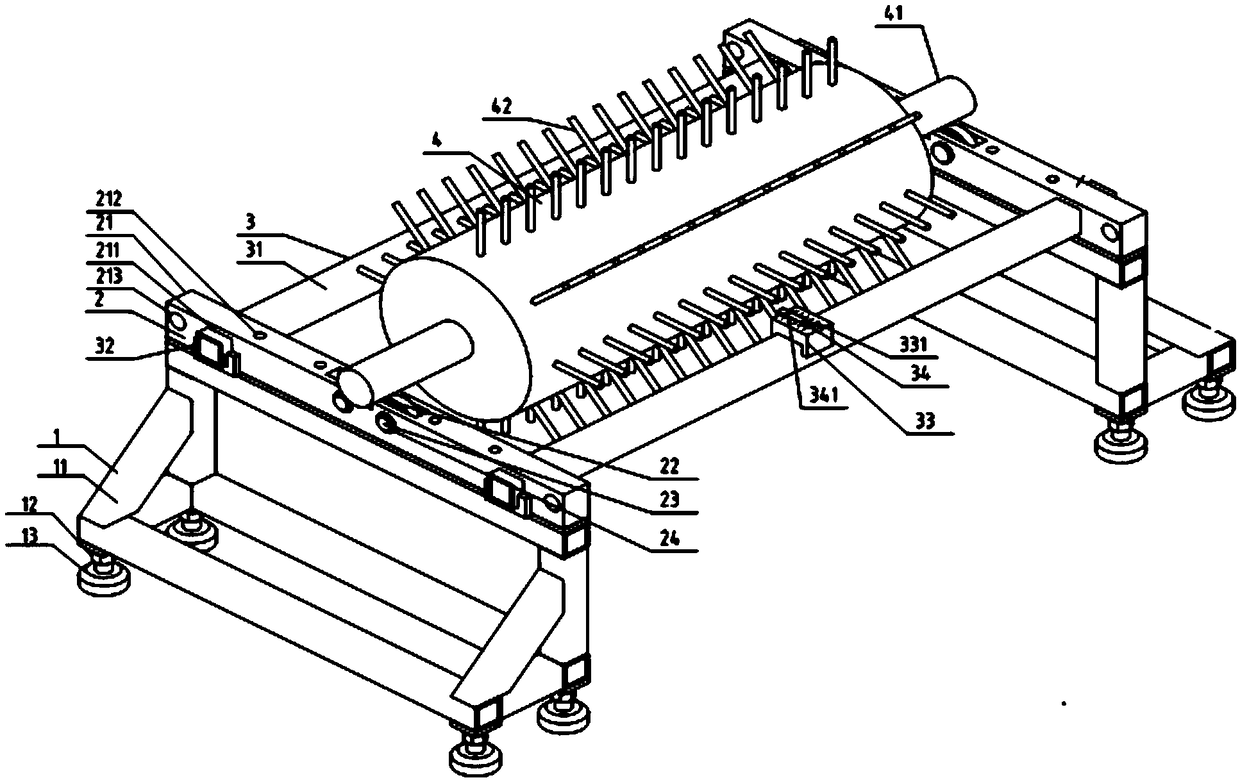

[0025] Example 1, see figure 1 and figure 2 , the present invention provides a technical solution: a multifunctional detection device for shaft parts, including a bracket assembly 1, a positioning support mechanism 2 and a measuring mechanism 3, the top end of the bracket assembly 1 is welded and fixed with a positioning support mechanism 2, the The top end of the positioning support mechanism 2 is movably connected with a measuring mechanism 3, and the measuring mechanism 3 is used to detect the detection shaft 4, and a journal 41 is respectively fixed in the middle of the two sides of the detection shaft 4, and the detection shaft 4 4 Through the rotational connection between the journals 41 at both ends and the positioning support mechanism 2, a plurality of roller rod teeth 42 are fixed on the outside of the detection shaft 4;

[0026] The bracket assembly 1 includes two bracket welds 11, the bottom ends of the bracket welds 11 are fixed with adjustment legs 13, and the ...

Embodiment 2

[0032] Example 2, see attached image 3 , the difference from Embodiment 1 is that the guide column 31 is specifically a circular structure, and there are three of them, and the two ends of the guide column 31 are respectively sleeved between the circular guide holes 213 of the two positioning motherboards 21 Between, the three guide columns 31 and the positioning motherboard 21 are respectively perpendicular to each other. The circular guide post has a simple structure and is easy to manufacture, especially suitable for making longer guide rails.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com