Detection tool for detecting hot-rolling forklift beam type steel size

A technology for detecting tools and beams is applied in the field of detection tools for detecting the dimensions of beams of hot-rolled forklift trucks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described now in conjunction with accompanying drawing.

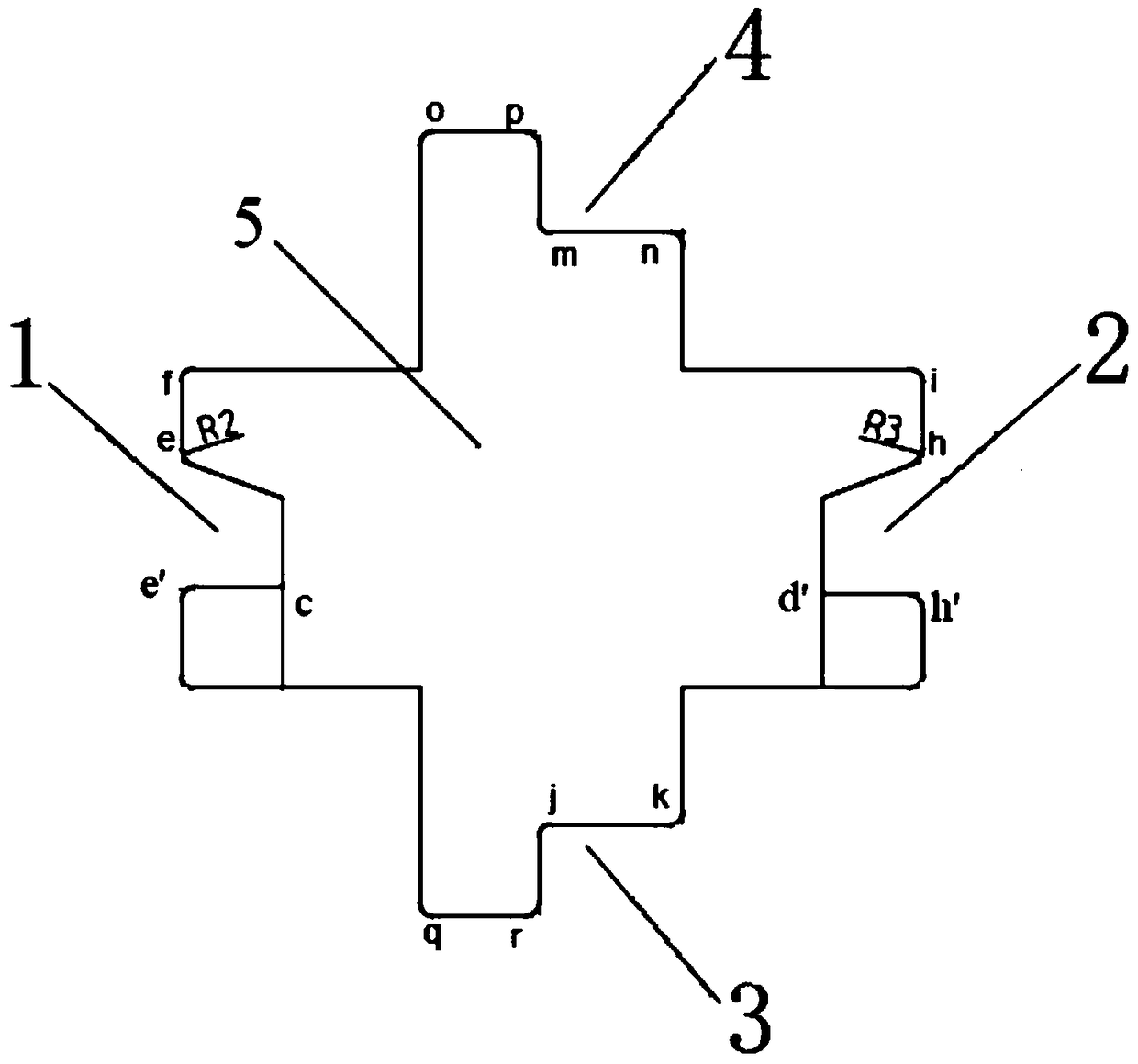

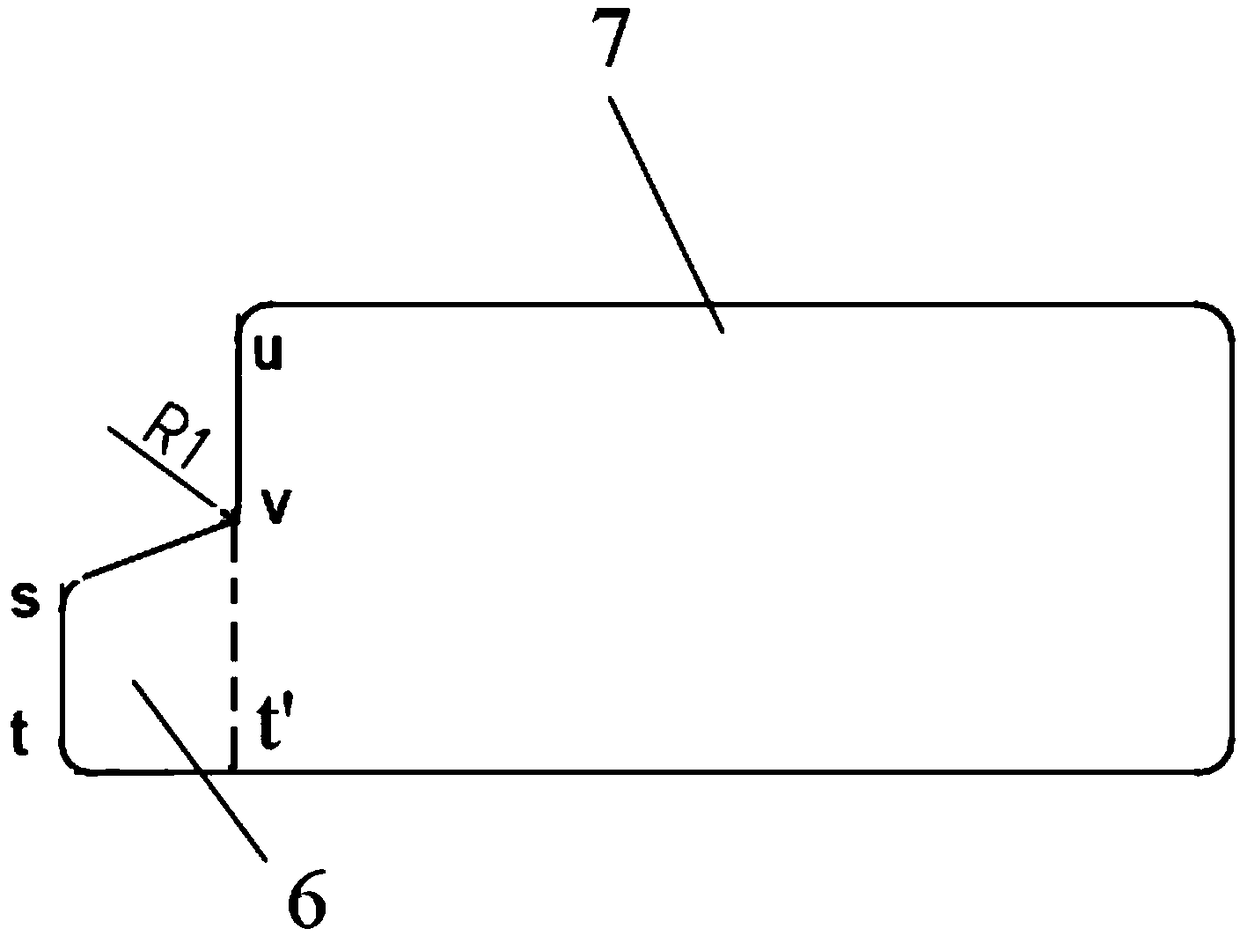

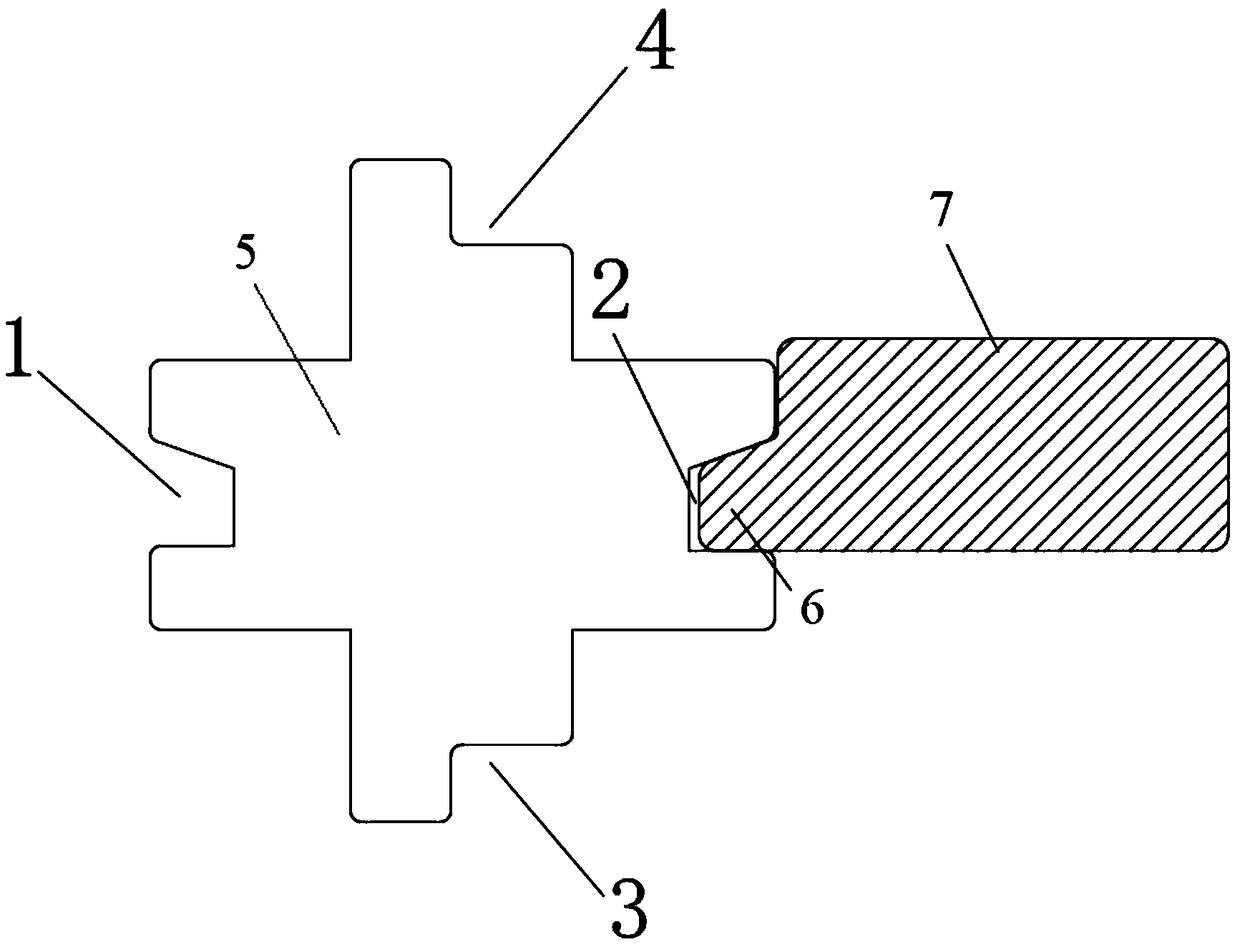

[0025] like figure 1 As shown, the present invention proposes a detection tool for detecting the size of the hot-rolled forklift beam profile steel, and quickly measures whether the boss width and height of the hot-rolled forklift beam profile steel are within the tolerance range, thereby improving production efficiency; it includes: measuring Body 5; the measuring body 5 has a cross-shaped structure, and the four ends of the measuring body are respectively provided with a first card slot 1, a second card slot 2, a third card slot 3 and a fourth card slot 4 for measuring The width of the bottom of the boss 6 and the height of the boss 6 of the hot-rolled forklift crossbeam steel; wherein, the first slot 1 and the second slot 2 have a symmetrical structure, and the third slot 3 and the fourth slot 4 have a symmetrical structure.

[0026] As one of the improvements of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com