A kind of maize husk peeling mechanical testing equipment

A technology for testing equipment and corn husks, applied in the direction of force/torque/power measuring instruments, measuring devices, instruments, etc., can solve the problems of lack of theoretical basis for the development of corn combine harvesters, and few basic theoretical studies of machinery and tools, etc., to achieve improvement Peeling performance, reliability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

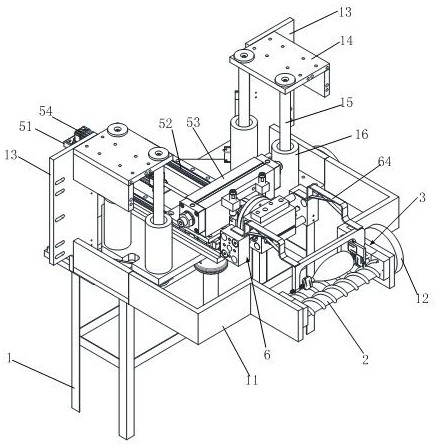

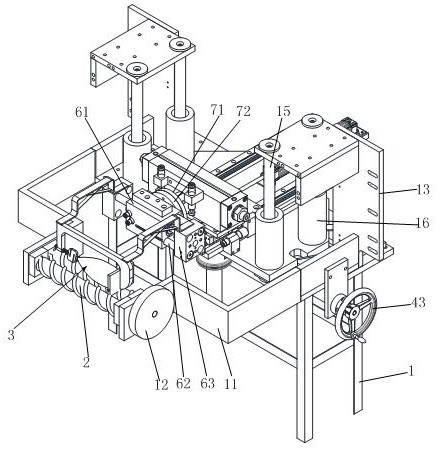

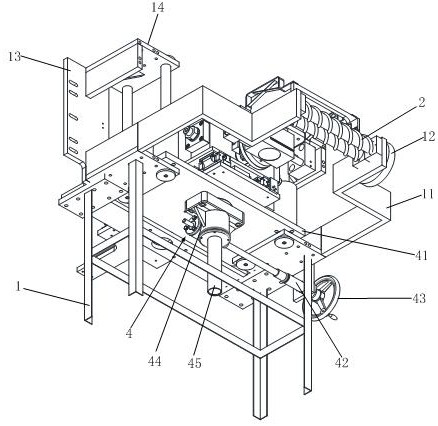

[0027] Example: such as Figure 1-Figure 3 As shown, a corn husk peeling mechanical testing equipment includes a frame 1, a peeling roller 2 is installed on the front side of the frame 1, and the peeling roller 2 is driven to rotate by a motor. A clamping device 3 for clamping corn 8 is installed above the peeling roller 2, and a lifting mechanism 4 for adjusting the position of the clamping device 3, a front and rear adjustment mechanism 5, a left and right adjustment mechanism 6 and a rotation adjustment mechanism are also installed on the frame 1. 7. After the corn 8 is installed on the clamping device and adjusted to a suitable position according to the experimental parameter settings, the peeling roller 2 rotates to peel off the corn husks, and at the same time, the stress of the corn 8 during the peeling process of the husks is tested.

[0028] A peeling roller support 11 is installed on the frame 1, and the two ends of the peeling roller 2 are installed on the peeling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com