TFT substrate

A substrate and substrate layer technology, applied in the direction of instruments, electrical components, circuits, etc., can solve the problems of PI liquid inflow, traces, uneven brightness of the display, etc., and achieve the effect of avoiding the problem of PImura

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

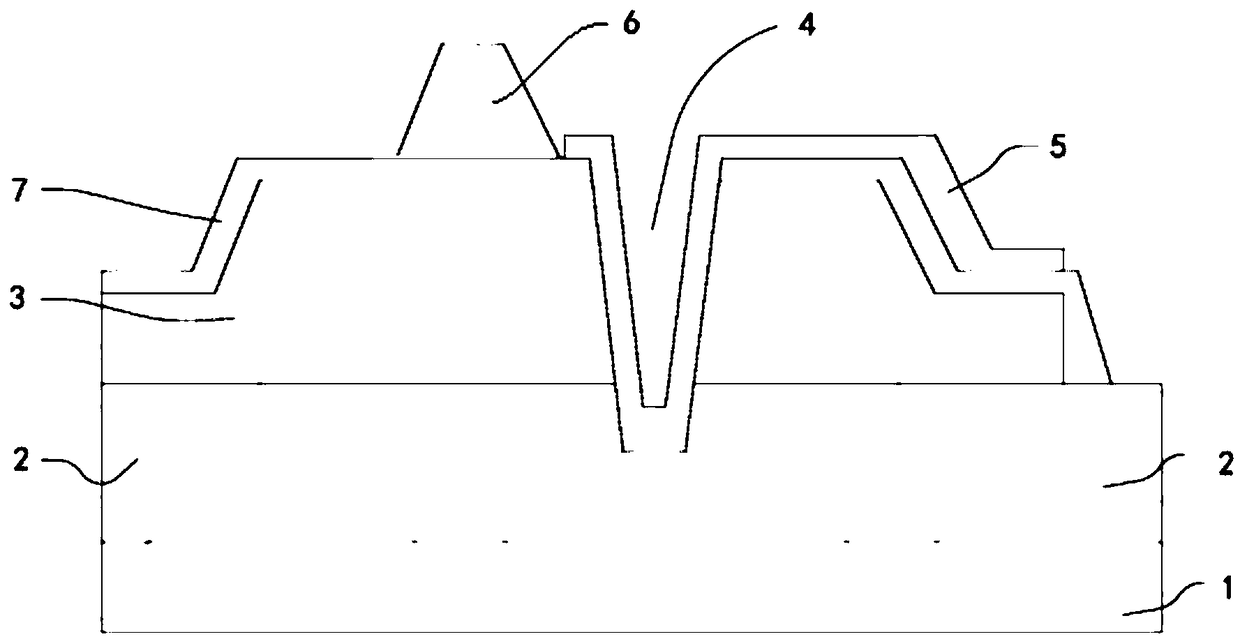

[0027] like figure 1 As shown, an embodiment of the present invention provides a TFT substrate, including a substrate layer 1, a thin film transistor 2, a color resistance layer 3, a via hole 4 and a pixel electrode 5, wherein the via hole 4 passes through the color resistance layer 3 so that the pixel The electrode 5 is connected to the thin film transistor 2 .

[0028] Wherein the color resistance layer 3 is also provided with a protrusion 6, which is arranged on one side of the via hole 4, and when the color resistance layer 3 is coated with PI liquid (polyimide liquid), the protrusion 6 can block the The surface tension of the PI liquid enables it to flow smoothly into and fill the via hole 4 .

[0029] In this embodiment, the protrusion 6 is made of a color-resist material and is formed by exposure. The color-resisting material involved includes one of the color-resisting materials such as R / G / B / Ps / BM, which can be specified according to needs and is not limited.

[00...

Embodiment 2

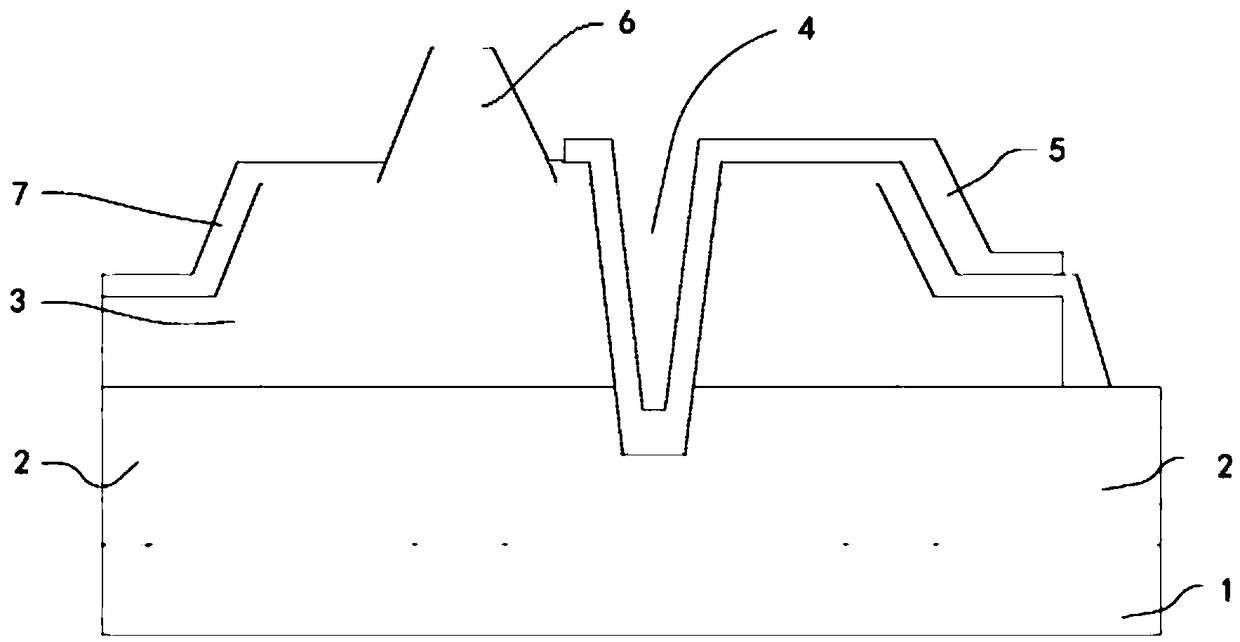

[0037] like figure 2 As shown, another embodiment of the present invention provides all the technical solutions including the TFT substrate of Embodiment 1, the difference is that the protrusion 6 and the color resist layer 3 are integrally formed. That is, a part of the color resist layer 3 protrudes upward to form a protrusion 6 . The protrusion 6 and the color-resist layer 3 are integrally formed, which can increase the stability between the protrusion 6 and the substrate and prevent it from falling off.

[0038] The beneficial effect of the present invention is: a kind of TFT substrate that the present invention relates to, it is by setting the protrusion 6 structure beside its via hole 4, to drain PI liquid to flow into the via hole 4, avoid PI liquid because of its own surface tension problem. The resulting accumulation around the via hole 4 effectively avoids the PI mura problem.

[0039] Further, the PI liquid will fill the via holes 4 after flowing into them, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com