An unequally divided commutator

A commutator and commutator piece technology, applied in the direction of current collectors, rotating current collectors, electrical components, etc., can solve problems such as noise, achieve the effects of reducing sparks, eliminating periodic noise, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

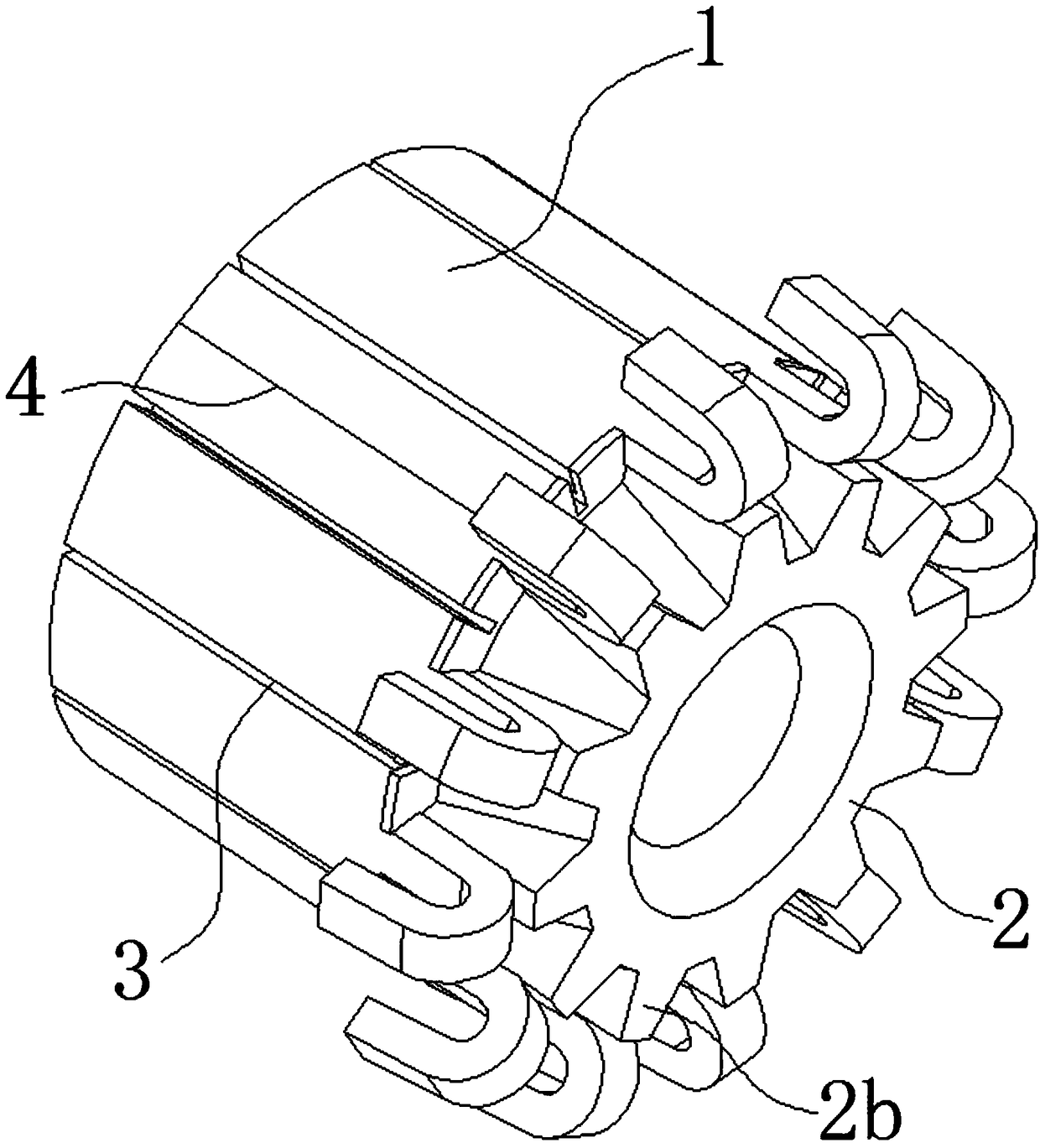

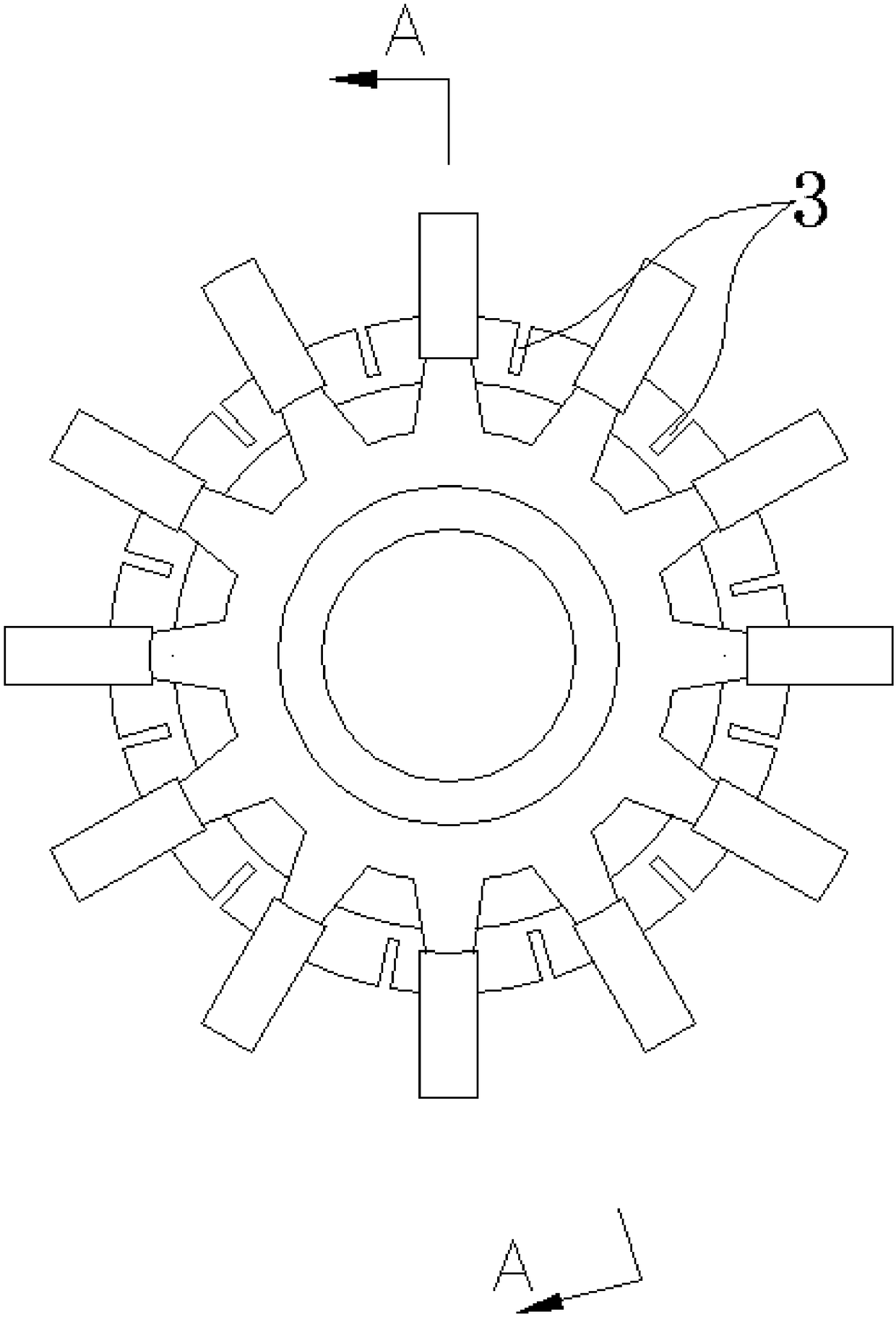

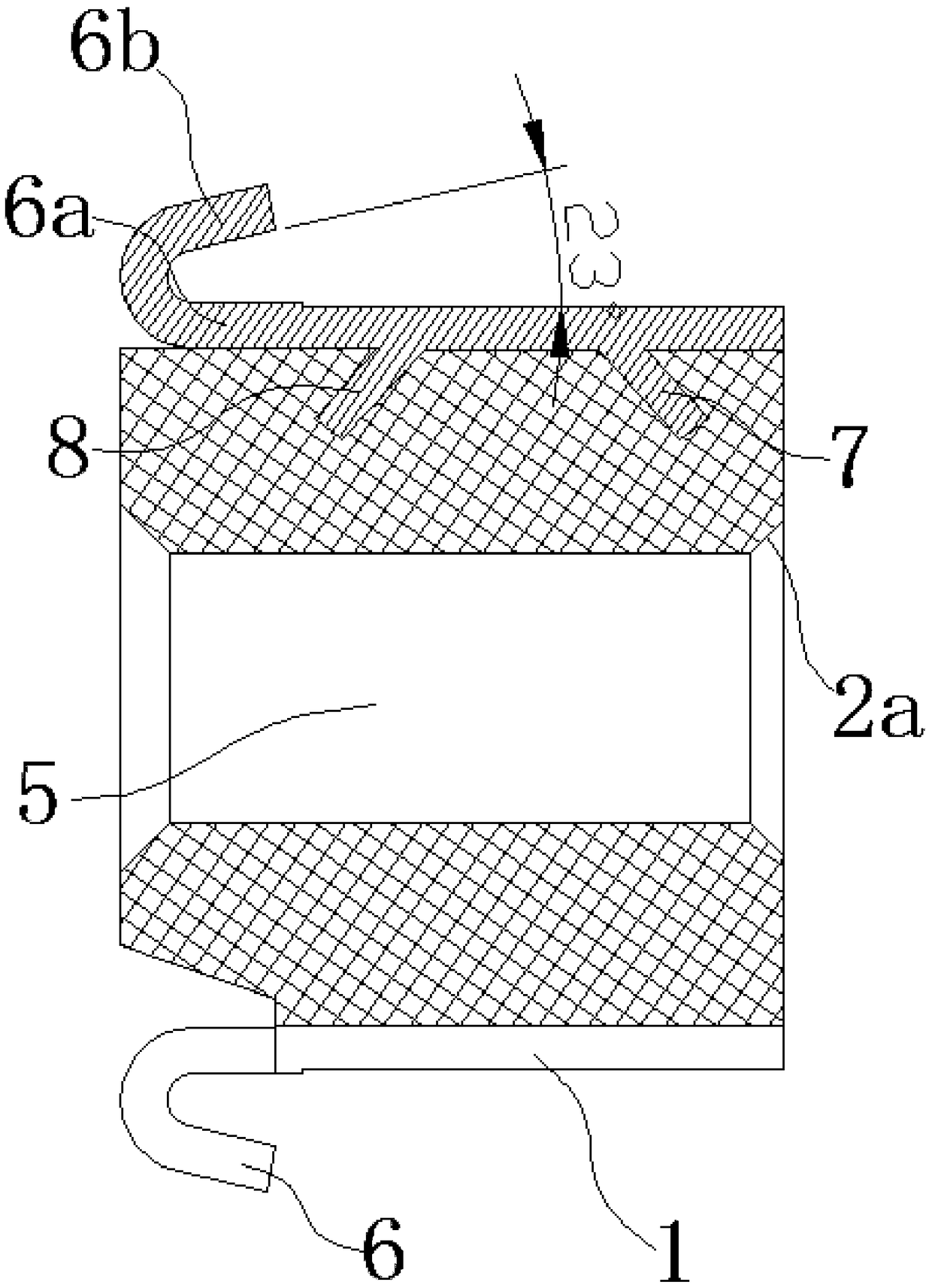

[0032] In order to achieve the purpose of the present invention, an unequal commutator includes: a sleeve 2; a commutation segment 1, a plurality of commutation segments 1 are annularly arranged on the circumferential surface of the sleeve 2, and adjacent commutation segments There are clearance grooves 3 between the segments 1, the clearance grooves 3 are parallel to the axis of the sleeve 2, the widths of the clearance grooves 3 are equal, and the widths of several commutator segments 1 are not equal to the same value.

[0033] The beneficial effect of adopting the above technical solution is that the design of the commutator divides the width and corresponding included angle of each commutator segment into several different values. This unequal-width design reduces sparks and noise during the operation of the commutator and improves the service life of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com