A 500kv intelligent substation pressure plate automatic calibration method

A smart substation and automatic calibration technology, applied in the direction of electrical components, circuit devices, information technology support systems, etc., can solve problems such as differences and inability to judge changes, and achieve the effects of solving alarm problems, reducing error rates, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0033] The present invention will be described in further detail below through the embodiments in conjunction with the accompanying drawings.

[0034] This embodiment provides a method for automatically checking the pressure plate of a 500kV intelligent substation, so as to automatically check the state of the pressure plate and ensure the correctness of the pressure plate switching.

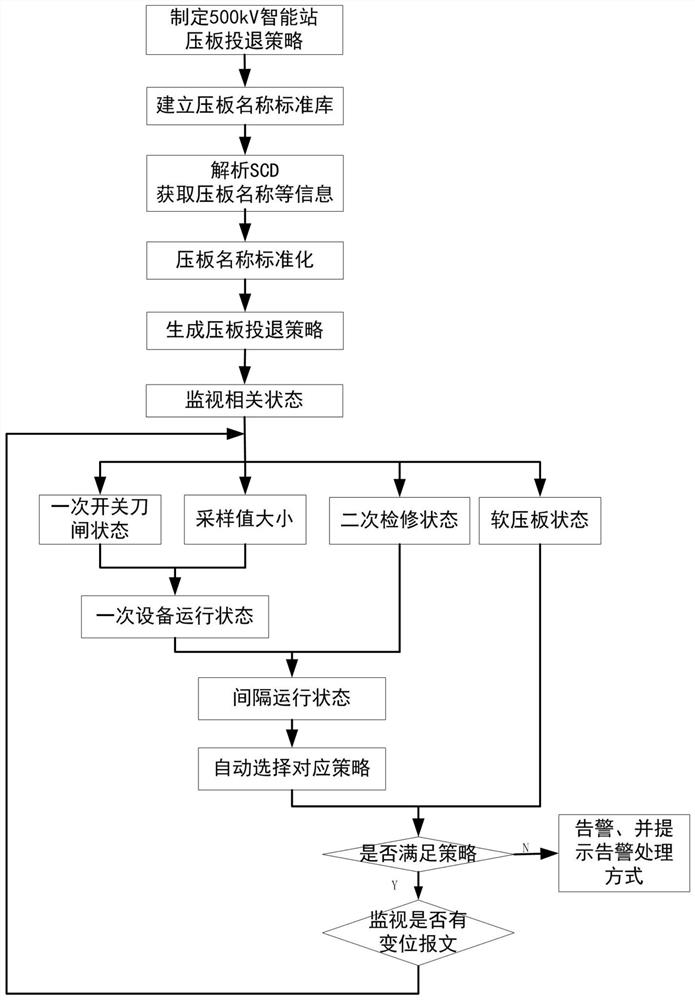

[0035] Such as figure 1 Shown is the work flow chart of the embodiment method of the present invention, specifically comprises the following steps:

[0036] Step 1: Compile the investment and withdrawal strategy of 500kV smart substation pressure plate; the strategy includes 500kV line, 500kV bus difference, main transformer, 220kV l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com