Hot-rolling seamless tube sizing roller cooling water ring

A technology of sizing rolls and cooling water, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of leakage, poor cleanliness, production rhythm damage, etc., to ensure the water-cooling effect, reduce production costs, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

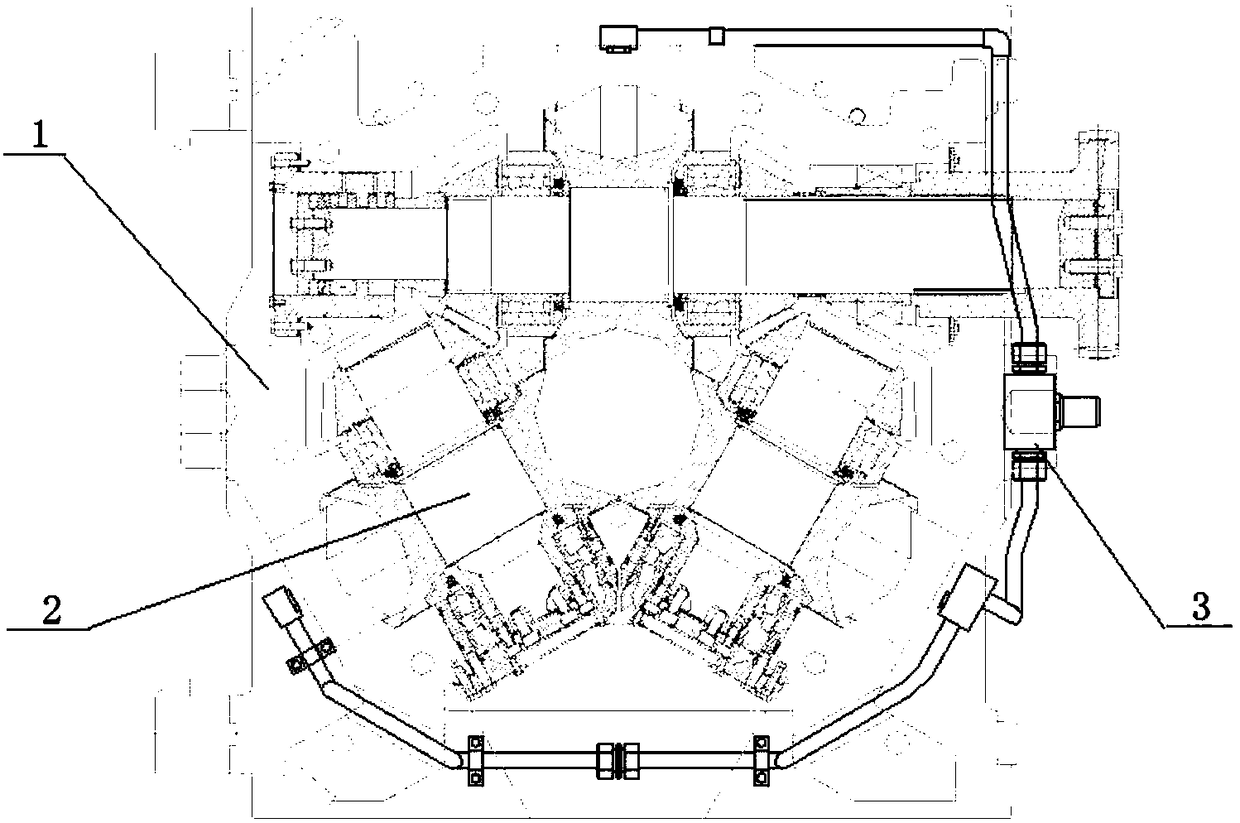

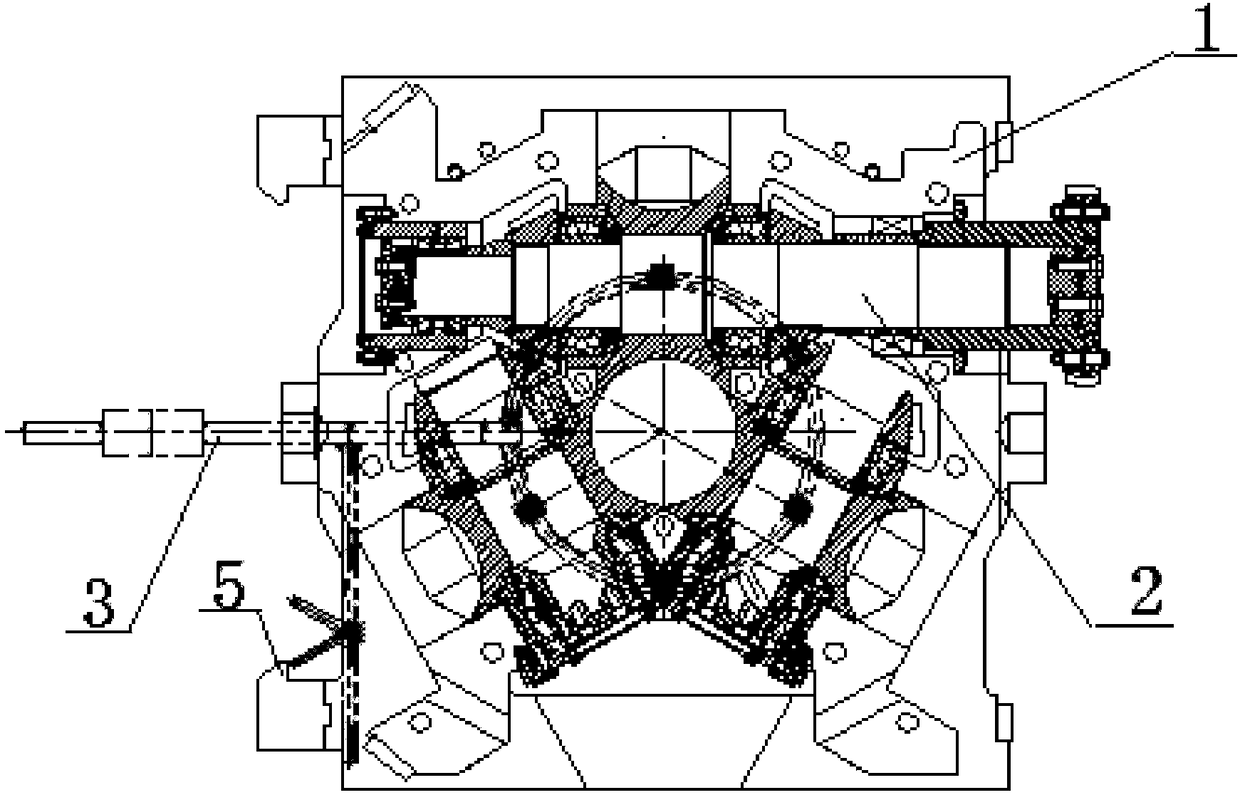

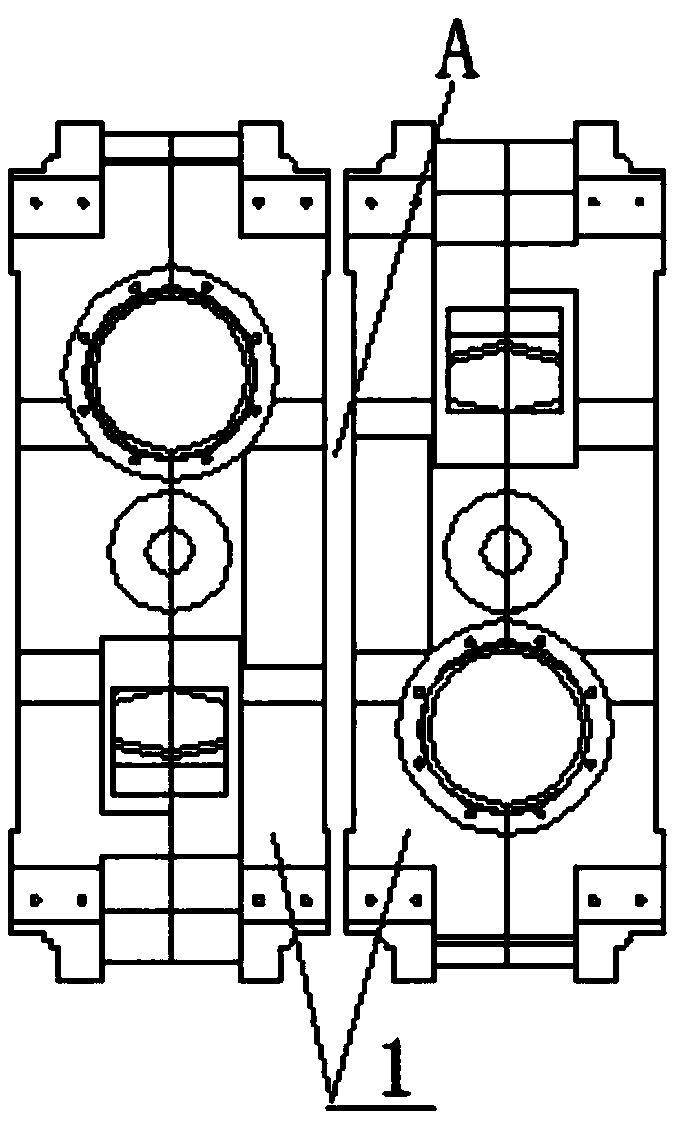

[0020] Such as Figure 2-Figure 4 As shown, a cooling water ring for a hot-rolled seamless pipe sizing roll in the present invention includes a cooling water ring 4, and the cooling water ring 4 is movably arranged in the gap between adjacent roll stands 1 ( Such as image 3 shown); as Figure 4 As shown, the cooling water ring 4 is composed of a water ring 41, a water inlet pipe 43, a support rod 1 45 and a support rod 2 47. One end of the water ring 41 is connected with a horizontally arranged water inlet pipe 43, and the water inlet pipe 43 is connected to an external connection through a quick connector 44. Water pipe connection; a plurality of nozzles 42 are uniformly arranged along the circumference of the water circle 41 and corresponding to the positions of the rolls 2 on both sides, and the number of nozzles 42 is a multiple of 3; the w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap