Modular detachable jacket

A modular, jacketed technology, applied in valve details, pipes/pipe joints/fittings, engine components, etc., can solve the problems of high cost, long manufacturing cycle of jacketed pipes, difficult installation and maintenance, etc. The effect of low maintenance cost, shortened project duration and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

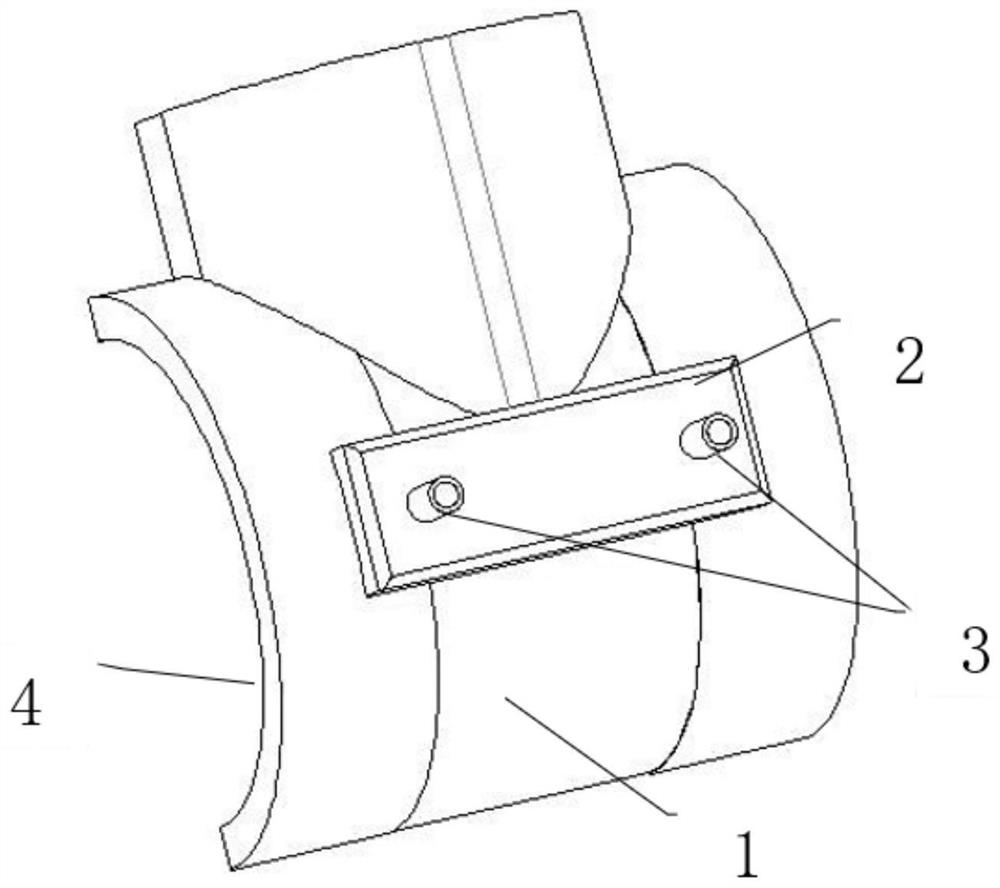

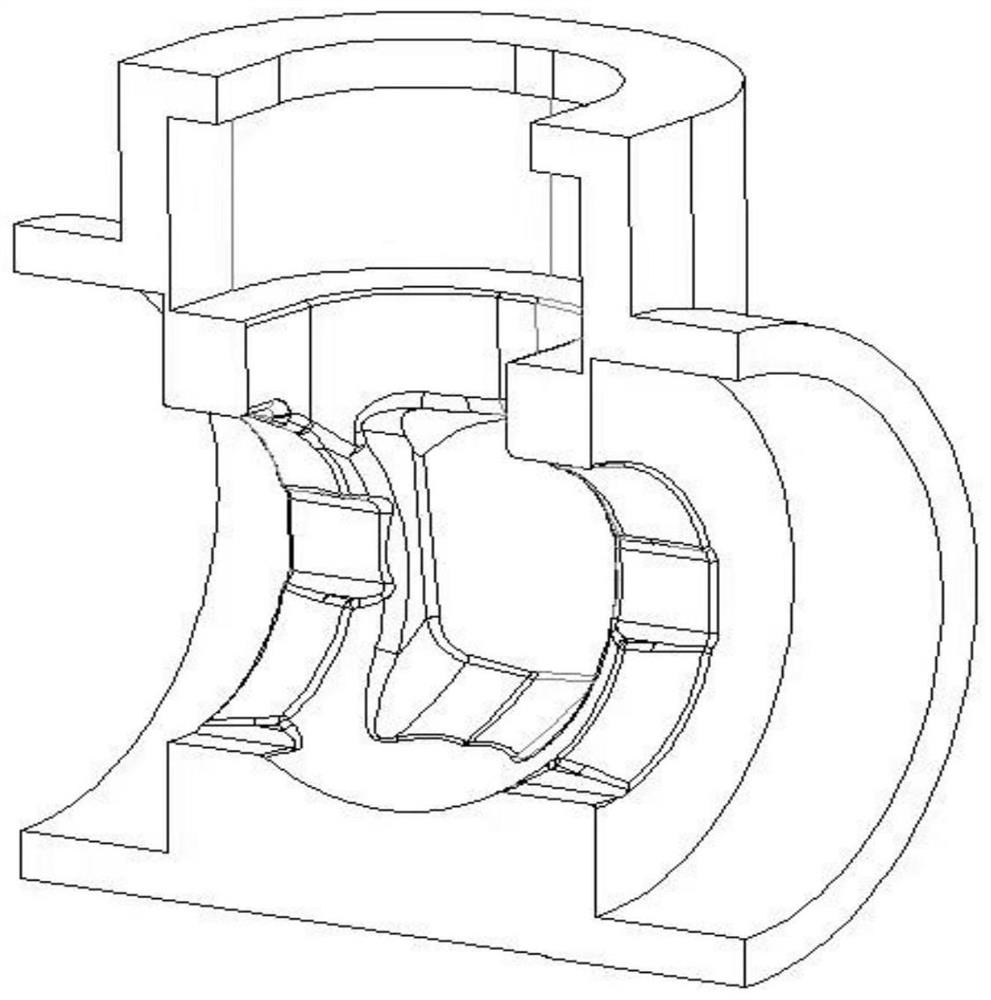

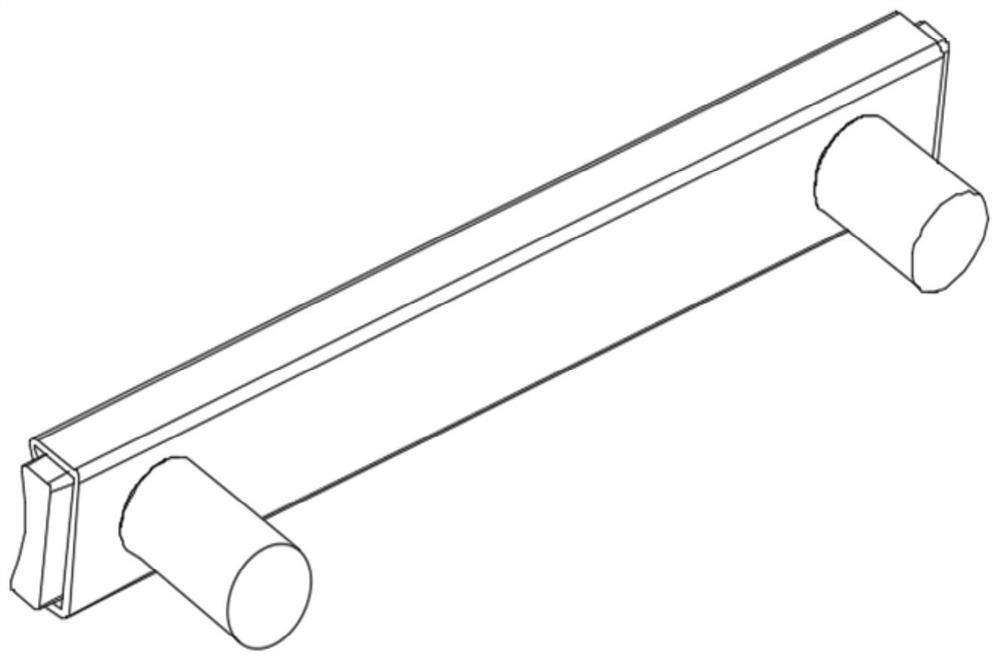

[0028] A modular detachable jacket provided in this example, the schematic diagram is as follows figure 1 , the schematic diagram of the heating element is shown in image 3 . In this embodiment, the heat tracing part is a valve with a flange; the heat conducting part 1 is casted by aluminum alloy, and its inner surface completely matches the outer shape of the valve. The parts are completely wrapped; the heat tracing part 2 is a special-shaped stainless steel square tube, which is embedded in the heat conducting part 1, and the 3 is the inlet and outlet of the heat tracing medium steam of the heat tracing pipe; the joint between the heat conducting part 1 and the heat tracing part is filled with soft heat conducting material 4. The thermal conductivity of the soft thermal conductive material 4 is greater than 10W / (m·K).

[0029] In this embodiment, the thermal conductivity of the heat-conducting element 1 is as high as 237W / (m·K). The steam of the heat-tracing medium passes...

Embodiment 2

[0031] A modular detachable jacket provided in this example is basically the same as in Example 1, the difference is that the heating element 2 adopts Figure 4 The circular steel pipe in the figure is embedded in the heat conducting element 1, which can achieve heat tracing performance equivalent to that of the first embodiment.

[0032] To sum up, the present invention has large heat transfer area, high thermal conductivity, uniform heat tracing without dead zone, comparable thermal start-up performance to traditional jackets, and can replace jackets for heat tracing of viscous and easily crystallized media, especially suitable for Irregular parts such as valves, pumps, instruments, flanges, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com