Descaling unit arrangement method and jet descaling method for jet descaling

A layout method and jet technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of the surface is not cleaned, the stability of the treatment is not high, and the board surface technology is not proposed, so as to improve the operation stability. Effect with reliability, low tension level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

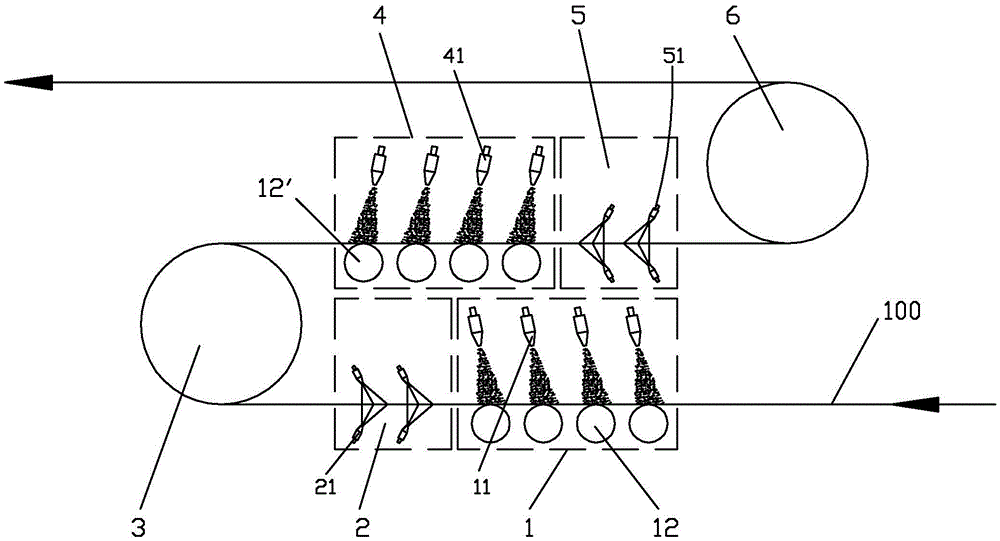

[0027] see figure 1 , a descaling unit arrangement method for jet descaling of the present invention, including sequentially setting at least one first mixing jet descaling unit 1 for cleaning the upper surface of the metal strip 100, washing the upper surface of the metal strip 100 The first low-pressure washing unit 2, the first turning roller 3 for realizing the metal strip 100 turning over once, at least one second mixed jet descaling unit 4 for cleaning the lower surface of the metal strip 100, and the flushing of the metal strip 100 The second low-pressure flushing unit 5 on the surface, and the second turning roller 6 for realizing the double turning of the metal strip 100 .

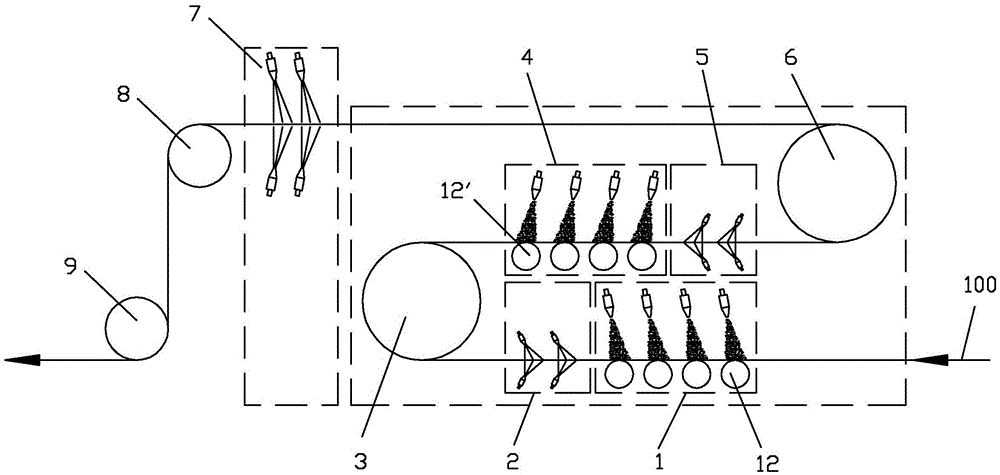

[0028] see figure 2 , which shows the second embodiment of the present invention. In this embodiment, the second turning roller 6 of the present invention is further provided with an air purging unit 7, third and fourth turning rollers 8, 9 in sequence.

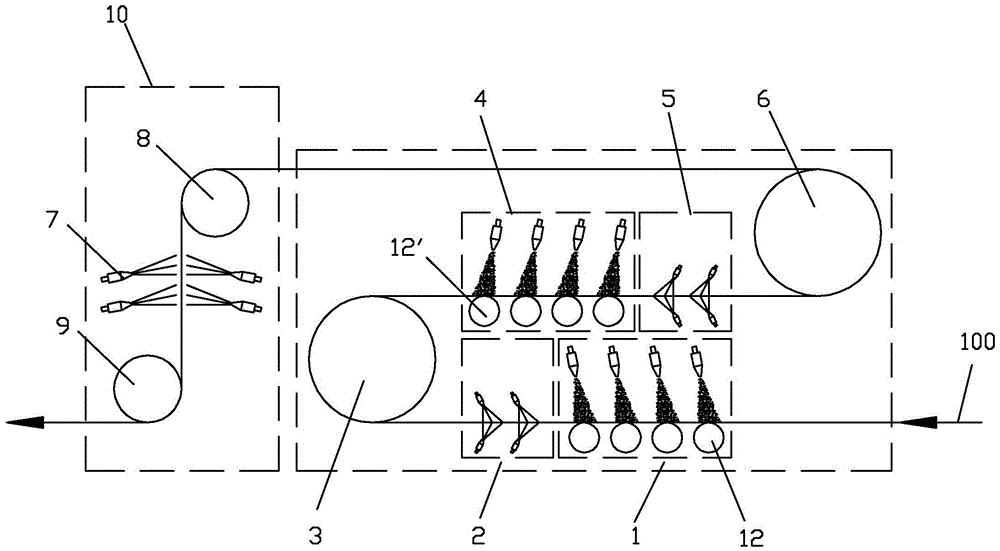

[0029] see image 3 , which is shown a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com