High-pressure water descaling device and method for forge piece

A high-pressure water descaling and pressurizing device technology, which is applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of not too long transfer time, long time, and poor fixation of conveyor belts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

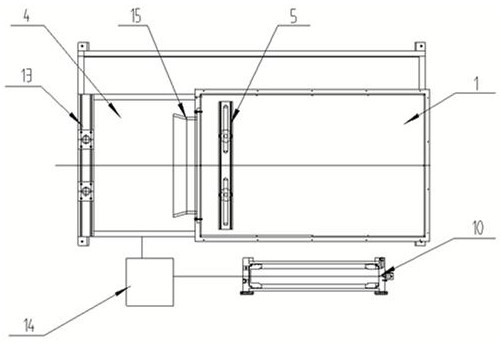

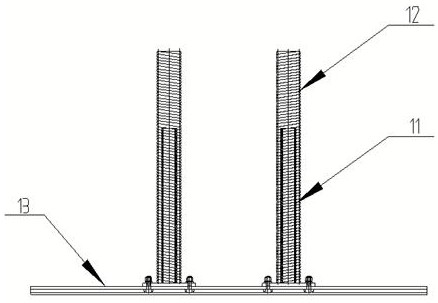

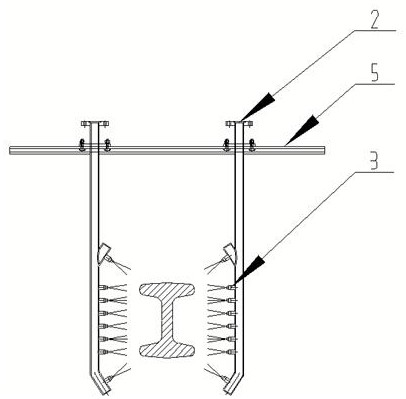

[0025] The present invention will be further described below with reference to the accompanying drawings.

[0026] Details: See Figure 1 to 4 A forgings, high-pressure water density, including spray assemblies and flexible detection assemblies, the spray assembly including the front side and bottom spray box 1, the spray case for high pressure in the forgings entered into it. The lyrence is disposed on the front side of the spray box, including the front side of the spray box, including the front side of the spray box, and the two rigid members are hit, and the upper exterior of the spring is a certain length. To form a free portion, the free portion of the two springs is an area passed by the forging, and the forging is passed from the free portion of the two spring 12 and then enters the spray box 1.

[0027] A returning groove 4 is provided at the bottom opening of the spray case, and the back water groove 4 is connected to the inlet end of the pressurizing device, and the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com