Tool for machining valve stem holes of two-pieces ball valves

A valve stem hole, two-piece technology, used in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of inconvenient operation and low processing efficiency of boring machines, and achieve simple structure, reduce processing inconvenience, and reduce manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

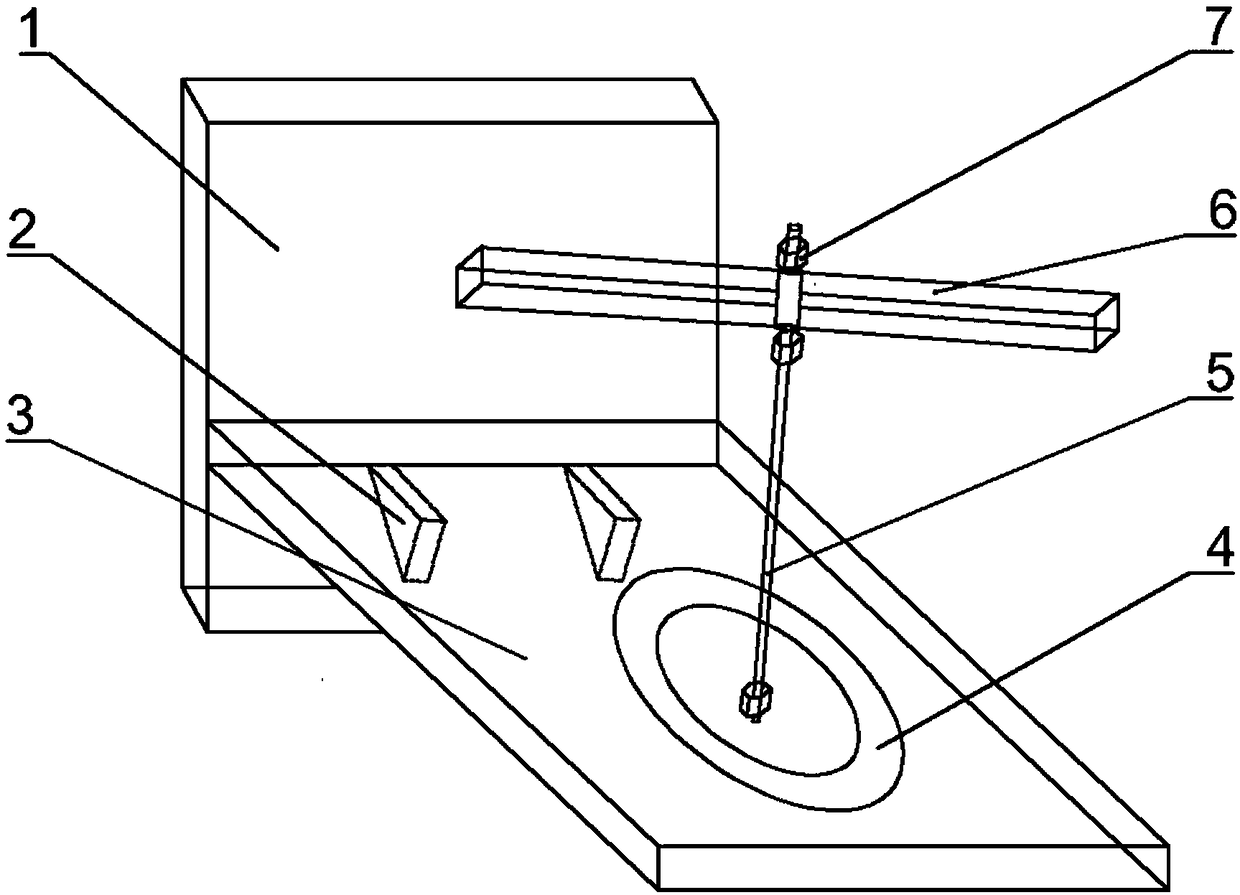

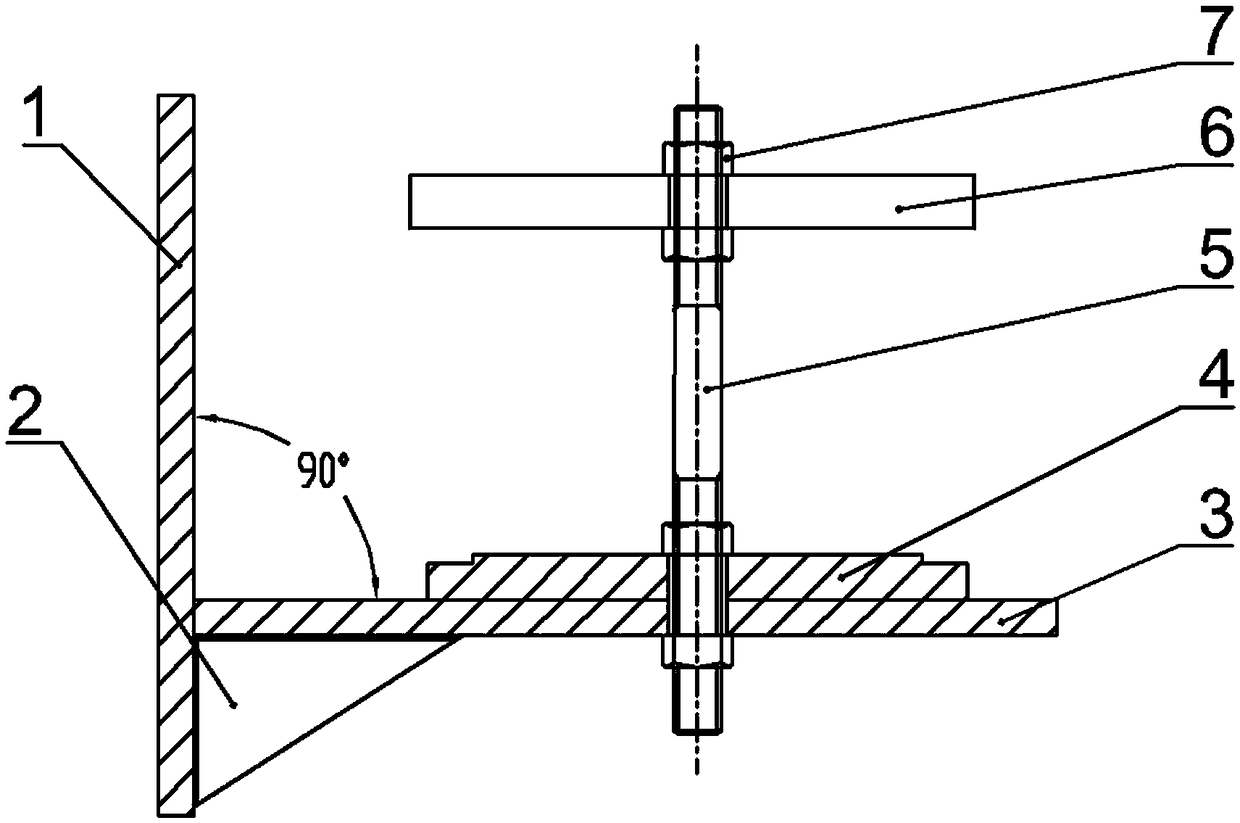

[0014] see Figure 1-2 , a tool for processing two-piece ball valve stem holes, including a clamping plate 1, a bottom plate 3, a seam plate 4, a stud bolt 5, a compression plate 6 and a pre-tightening nut 7, the clamping plate 1 and the bottom plate 3 is fixedly connected at a 90° right angle. The seam plate 4 is fixed on the bottom plate through the stud bolt 5 and the early warning nut 7. There is a threaded hole in the middle of the bottom plate 3. One end of the stud bolt 5 is connected to the threaded hole. The seam plate 4 There is a through hole in the center, the through hole is set on the outside of the stud bolt 5 and fixed with the early warning nut 7, the compression plate 6 is fixed on the upper end of the stud bolt 5 through the pre-tightening nut 7, and the compression is adjusted according to the size of the clamping valve body. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com