Big width laser marking solar cell

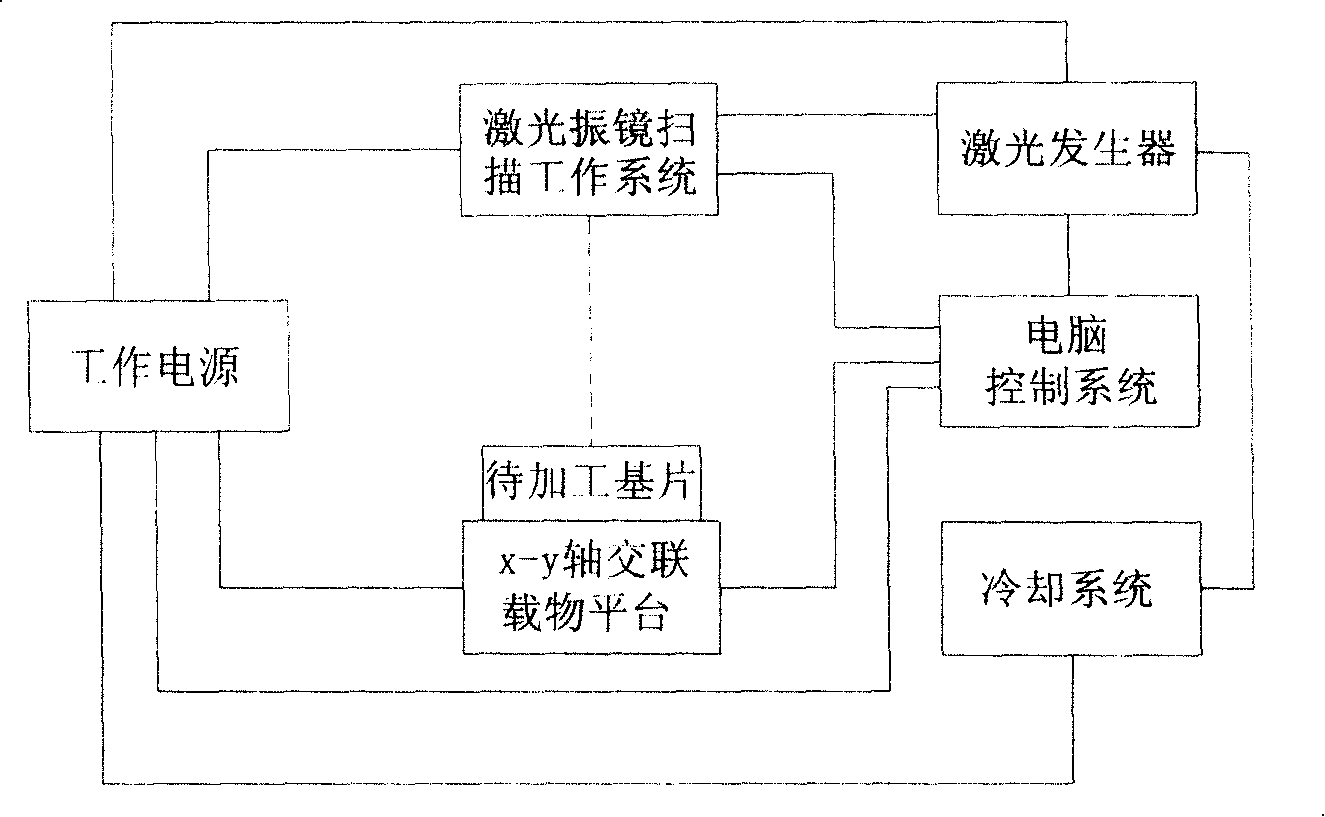

A solar cell and laser marking technology, which is applied to circuits, electrical components, sustainable manufacturing/processing, etc., can solve problems such as marking large-format thin-film batteries, and achieve improved photoelectric conversion efficiency, fast marking speed, The effect of increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

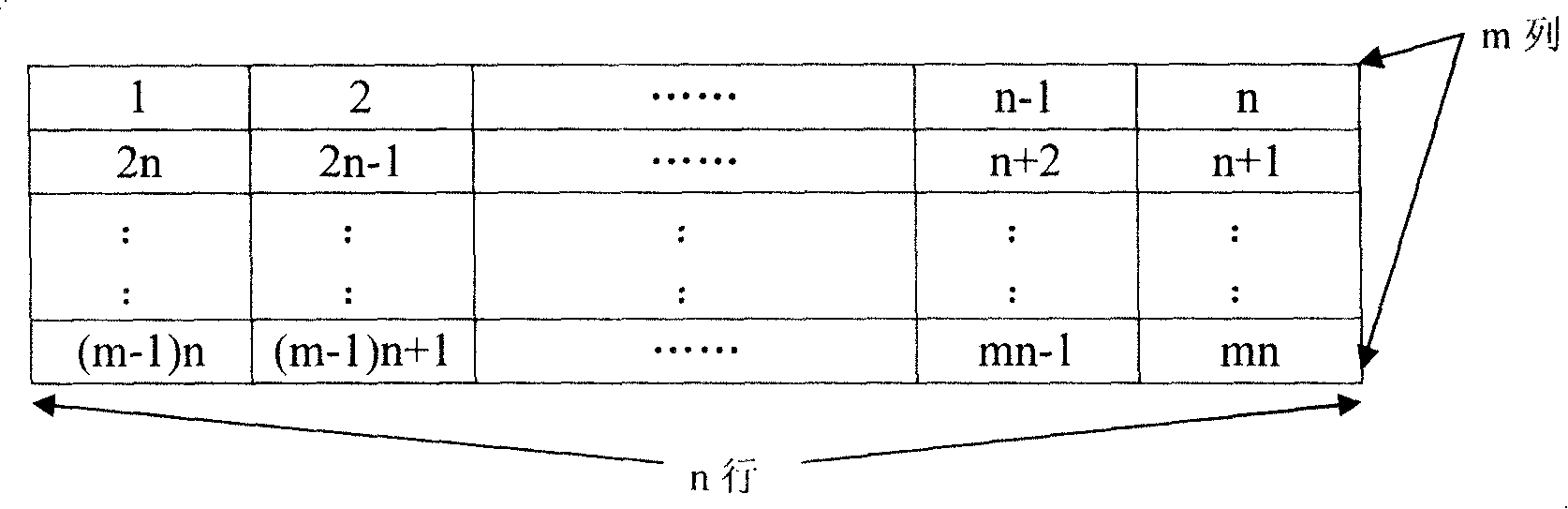

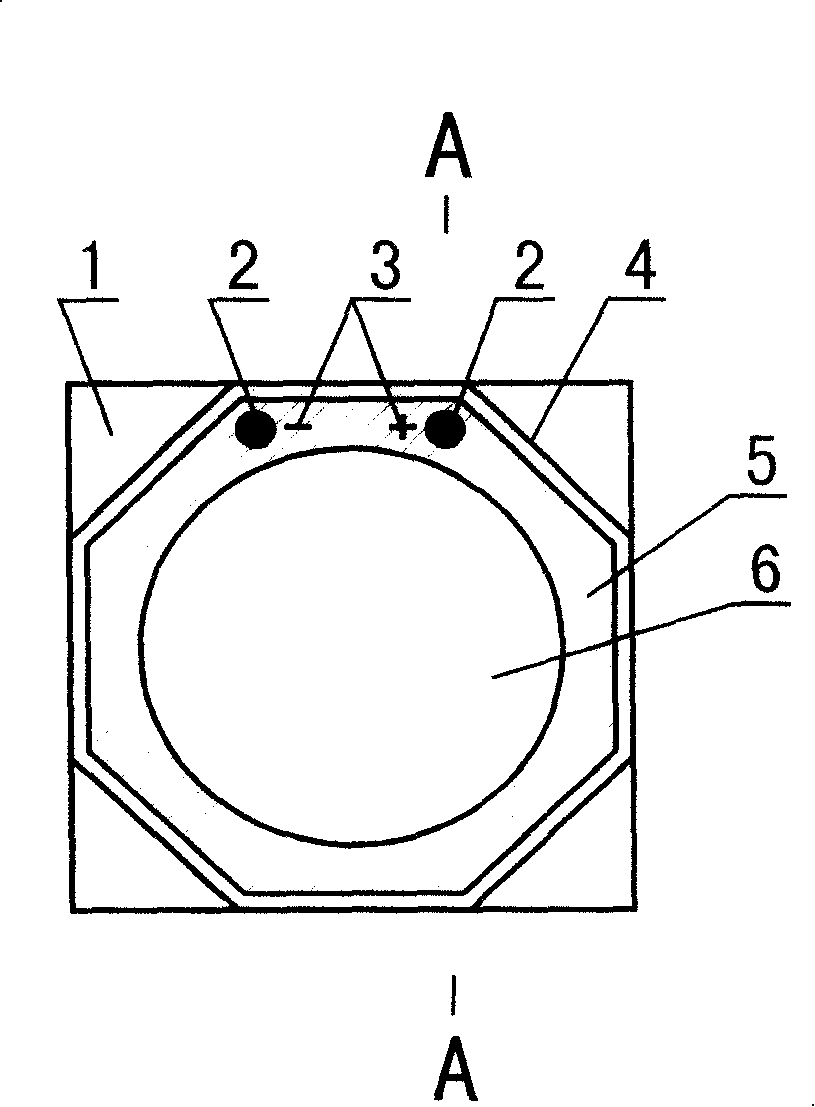

[0036] Example 2, embodiment figure, see figure 1 and Figure 7 Same as above, m=4, n=2, produce amorphous silicon thin-film solar panels with unit cell spacing of 10mm and external dimensions of 1000mm×2000mm×3.0mm.

[0037] Front electrode graphic production: place the composite transparent conductive film glass film with a size of 1000mm×2000mm×3.0mm facing up, place it on the X-Y axis loading work platform, start the large-format infrared laser marking system, and import the front electrode of the battery. engrave graphics, and set the marking range of the laser galvanometer scanning system to 500mm×500mm, divide the 1000mm×2000mm×3.0mm substrate to be marked into 8 marking areas of 500mm×500mm, and adopt multi-format marking In the way of engraving, 100 insulating isolation lines parallel to the long side with a spacing of 10mm are marked on the continuous conductive film of the substrate, see Figure 7 The part shown in 1'. In this way, the continuous conductive film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com