Sliding pair driven omni-directional large-rotating angle high-precision posture adjustment robot

A technology of moving pairs and large turning angles, applied in the directions of manipulators, manufacturing tools, hand-held tools, etc., can solve problems such as difficulty in popularization and application, and achieve the effect of symmetrical structure, reduced gap, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

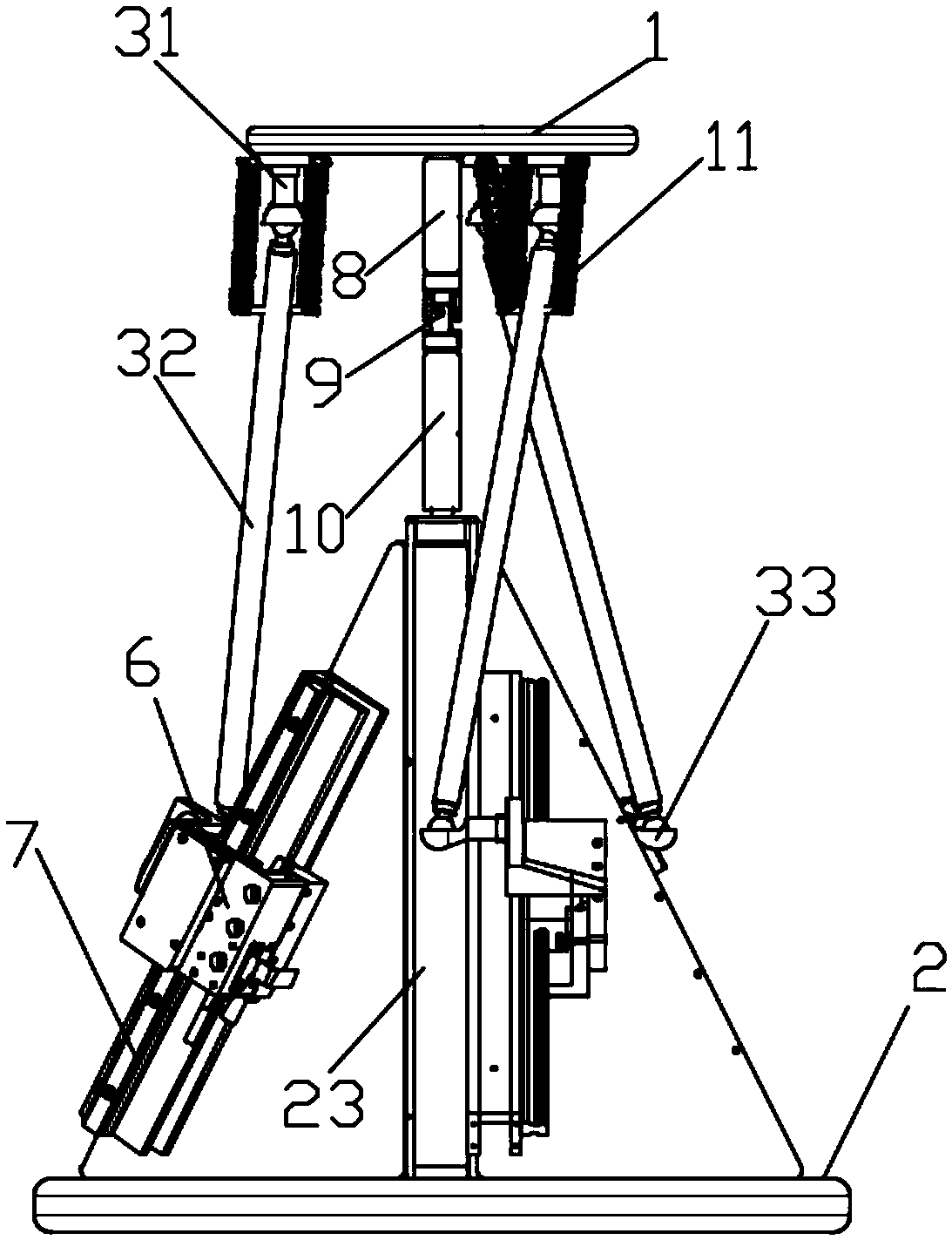

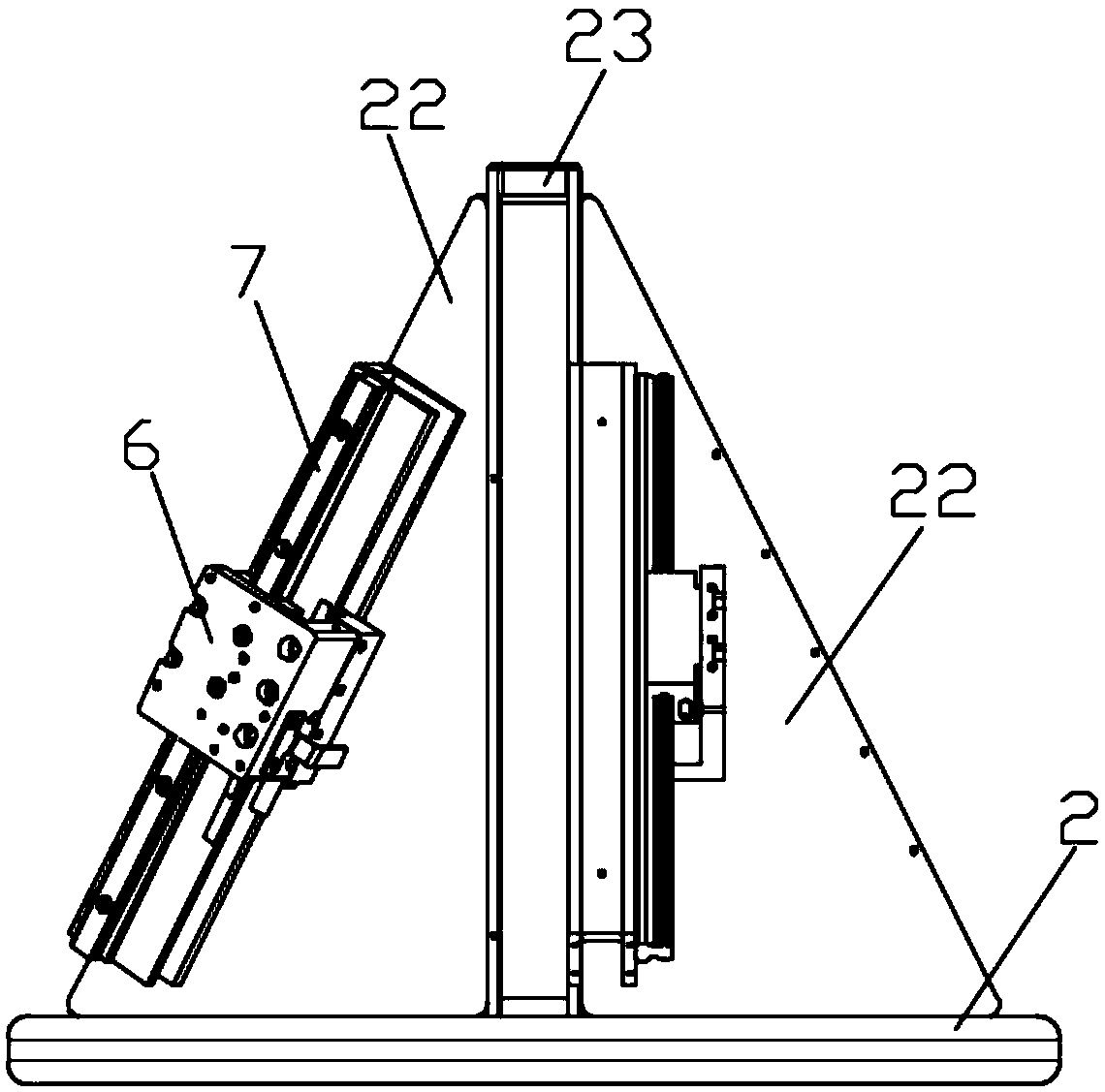

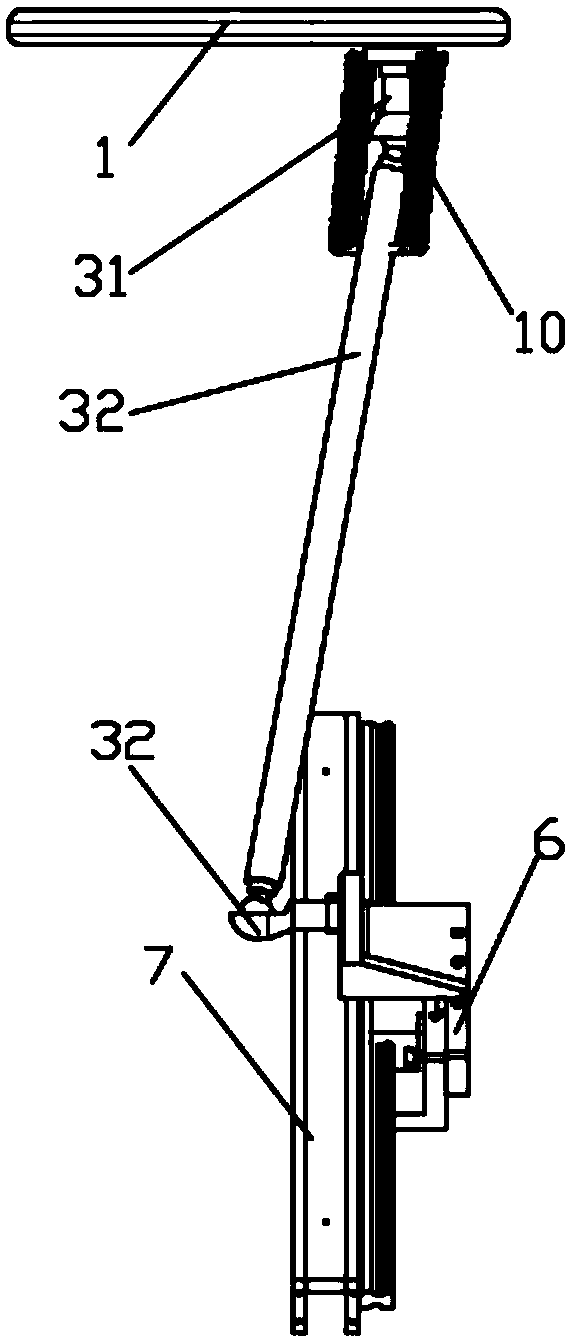

[0023] Such as Figure 1-Figure 3 As shown, an omnidirectional large-angle high-precision attitude adjustment robot driven by a moving pair of the present invention includes a movable platform 1, a base 2, a connecting assembly, a moving pair, a center rotating branch chain and a controller.

[0024] See details Figure 1-Figure 3 , the movable platform 1 in this embodiment can be installed or provided with functional tool components, preferably a jig for fixing 3C product materials. The shape of the movable platform 1 is circular or triangular, and it can also be other irregular types. The platform 1 is an inscribed triangle, and a group of connecting components are respectively arranged on the centers of the three sides. The connecting components make the movable platform 1 rotate in multiple directions to drive the movement of the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com