An emergency stop assistant device and an emergency stop method

A technology of emergency braking and auxiliary devices, applied in the direction of braking transmission devices, manual starting devices, brakes, etc., can solve the problems of difficult response of hands and feet, limited braking torque, low safety, etc., to achieve increased safety and low cost , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

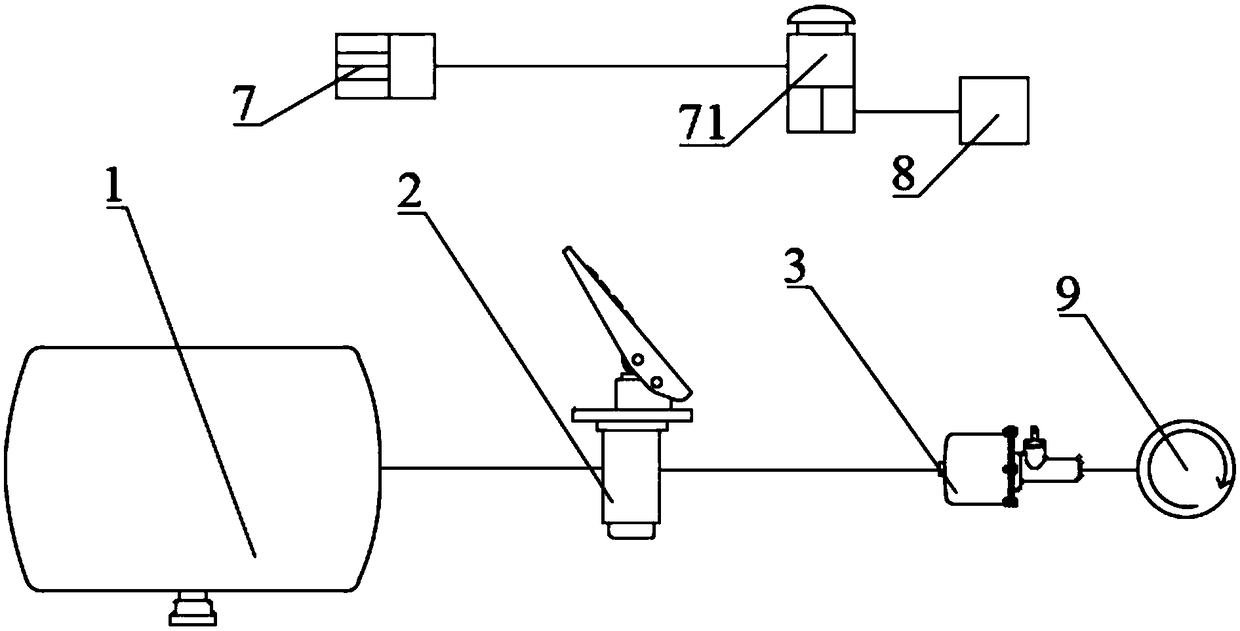

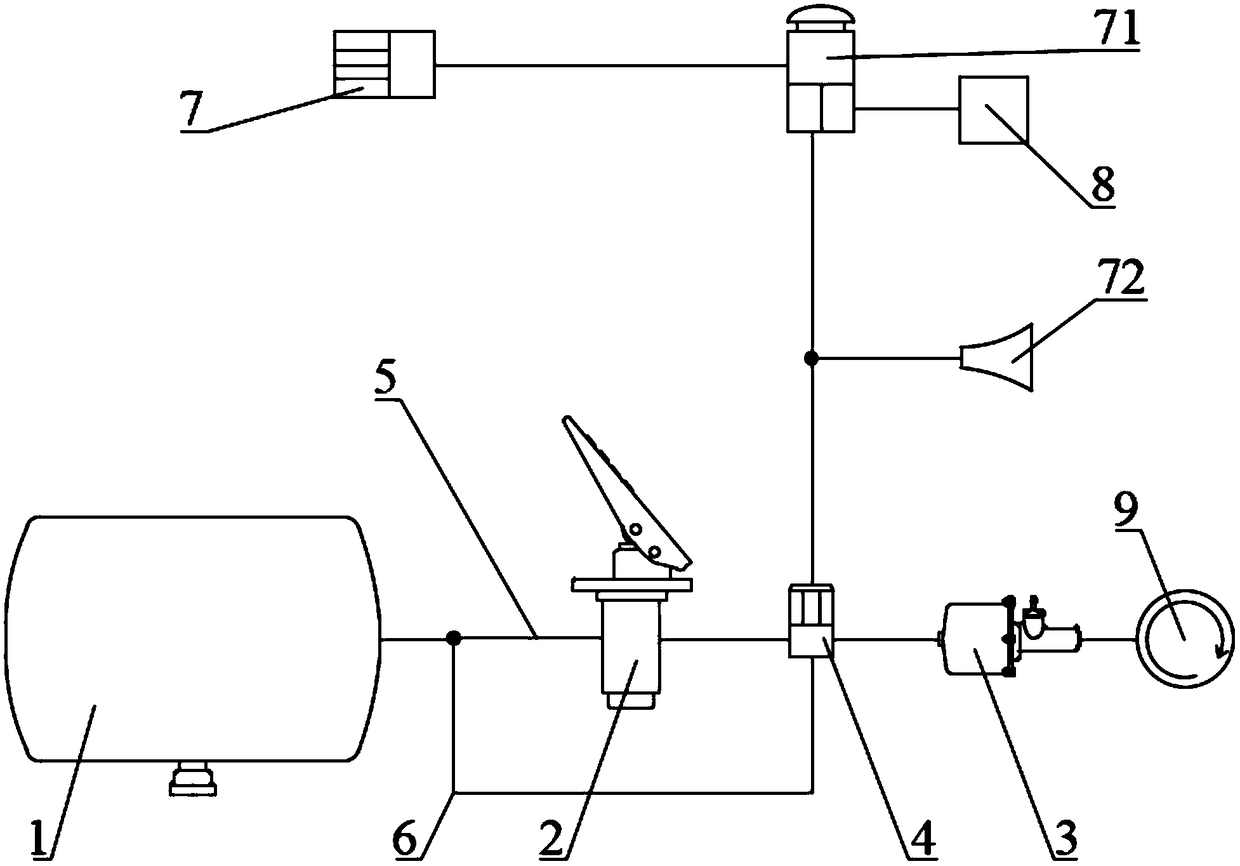

[0043] Please refer to the attached figure 2 As shown, an emergency brake auxiliary device includes an emergency brake button 71, a generator 7, an air storage tank 1, an air brake valve 2 and an air booster pump 3, and the air storage tank 1 and the air brake valve 2 connection, a pneumatic solenoid valve 4 is arranged between the air brake valve 2 and the air booster pump 3, the emergency brake button 71, the generator 7 and the pneumatic solenoid valve 4 and the brake valve 8 are electrically connection; the pneumatic solenoid valve 4 is a three-way structure, the pneumatic solenoid valve 4 is provided with a first outlet, a second outlet and a third outlet, the first outlet is connected to the air booster pump 3, the The second outlet is connected to the air brake valve 2, and the third outlet is connected to the second brake pipe 6; the pneumatic solenoid valve 4 is a two-position three-way solenoid valve; it also includes a first brake pipe 5 and The second brake pipe ...

Embodiment 2

[0045] An emergency braking method based on the emergency braking auxiliary device of Embodiment 1, is characterized in that it includes the following steps:

[0046] S1: Press the emergency brake button 71, the generator 7 supplies power to the pneumatic solenoid valve 4 through the emergency brake button 71, and at the same time, de-energizes the brake valve 8;

[0047] S2: The pneumatic solenoid valve 4 is energized, disconnecting the connection between the first outlet and the second outlet, and connecting the first outlet and the third outlet;

[0048] S3: The air storage tank 1 communicates with the air booster pump 3, the pressurized air in the air storage tank 1 passes through the third outlet and the first outlet, and is input into the air booster pump 3 Inside.

[0049] S4: the air booster pump 3 provides brake fluid for the brake 9 to brake;

[0050] S5: the brake valve 8 is de-energized, and the front brake of the bridge brakes the bridge;

[0051] S6: release t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com