Roll-to-roll holographic anti-counterfeiting high-precision positioning bronzing die-cutting machine

A holographic anti-counterfeiting, roll-to-roll technology, applied in winding strips, thin material handling, transportation and packaging, etc., can solve problems such as incomplete bronzing, uneven stamping paper, inaccurate positioning of stamping paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is specifically described below by way of examples.

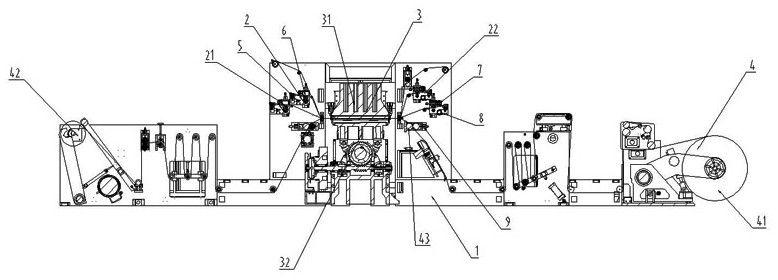

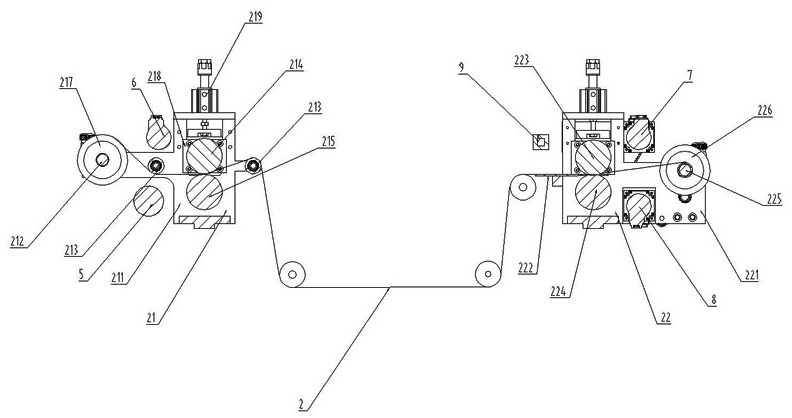

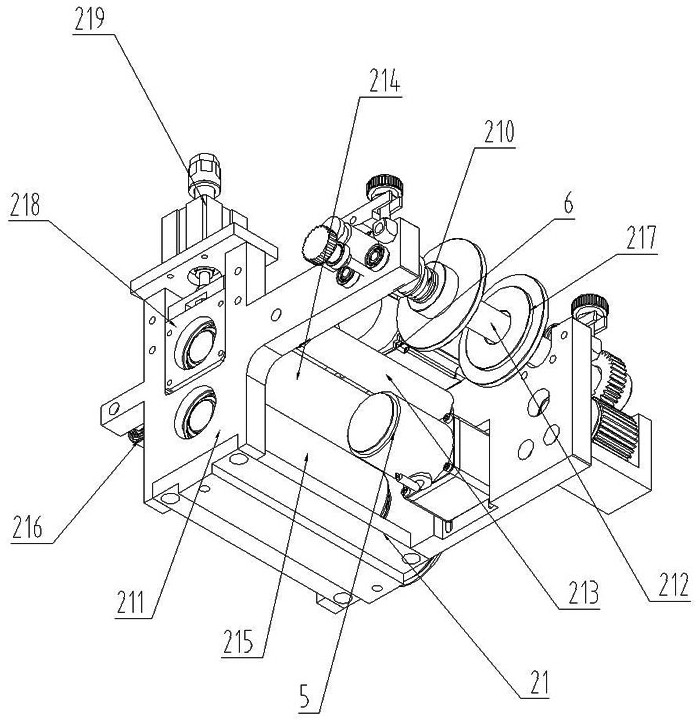

[0020] like figure 1 , figure 2 As shown, this embodiment discloses a roll-to-roll holographic anti-counterfeiting high-precision positioning hot stamping die-cutting machine, including a frame 1, and a hot stamping paper conveying mechanism 2, an embossing unit 3 and a paper feeding mechanism 4 are arranged on the frame 1, Embossing unit 3 comprises upper mold 31 and lower mold 32, and paper feeding mechanism 4 comprises feeding rack 41 and paper receiving rack 42, and feeding rack 41 is installed on one side of embossing unit 3, and paper receiving rack 42 is installed on embossing unit 3 on the other side, specifically as figure 2 As shown, the bronzing paper conveying mechanism 2 includes a feeding device 21 and a receiving device 22, the feeding device 21 is arranged on one side of the embossing unit 3 corresponding to the paper receiving frame 42, and the receiving device 22 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com