Manual water-pressing device with automatic weight sensing function

An automatic induction and water pressure device technology, applied in liquid distribution, packaging, distribution devices, etc., can solve the problems of no real-time detection of barreled water buckets, unsatisfactory structural design of manual water pressure devices, etc., and achieve ideal structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] refer to Figure 5 with Image 6 . The manual water press with weight automatic sensing function includes a protective shell 21 detachably installed on the water outlet of the barreled water bucket 1 through the connector 20. The protective shell 21 is movable with a manual plug 22. The manual plug 22 can move up and down through the upper port of the protective shell 21, and also includes a hand pressing part 3 matched with the top surface of the protective shell 21. The hand pressing part 3 includes a lower connecting part 31 and a The hand pressing part 32, the bottom surface of the lower connecting part 31 is provided with a notch 310 detachably connected to the upper end of the manual plug head, and the hand pressing part 32 is a rubber part with concave-convex texture on the top surface. The upper end of the manual plug is sleeved with a hand pressing piece. When the manual plug is pressed down to reach the position, the bottom surface of the lower connection pa...

Embodiment 2

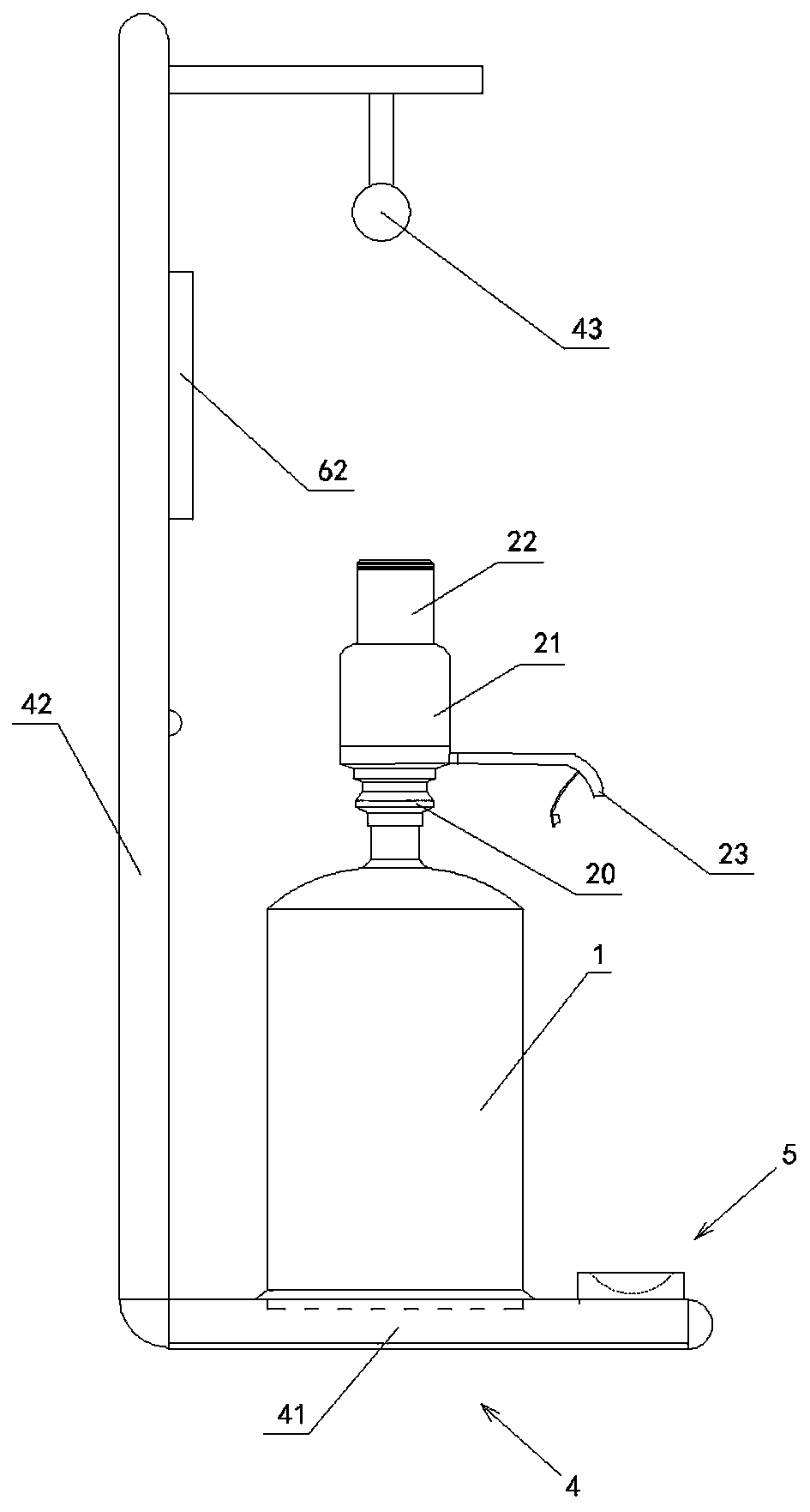

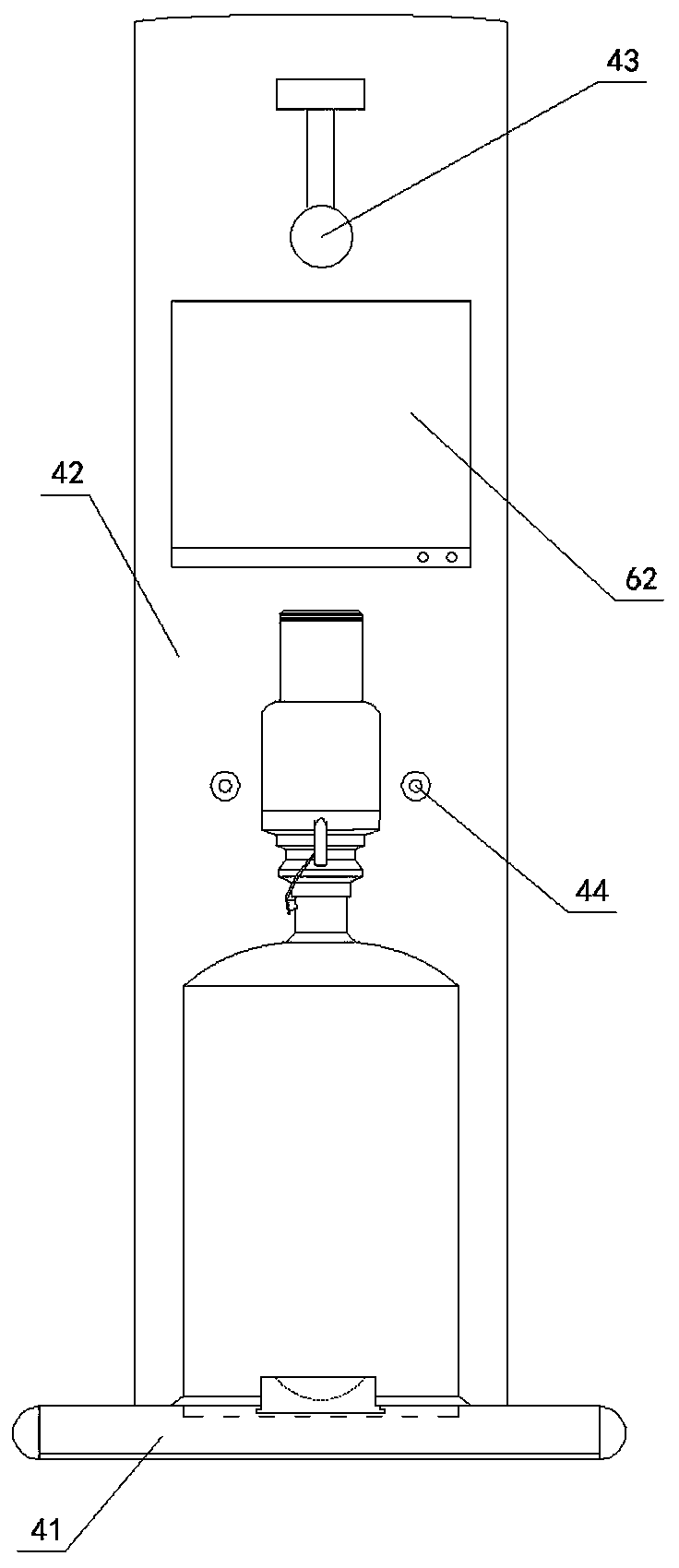

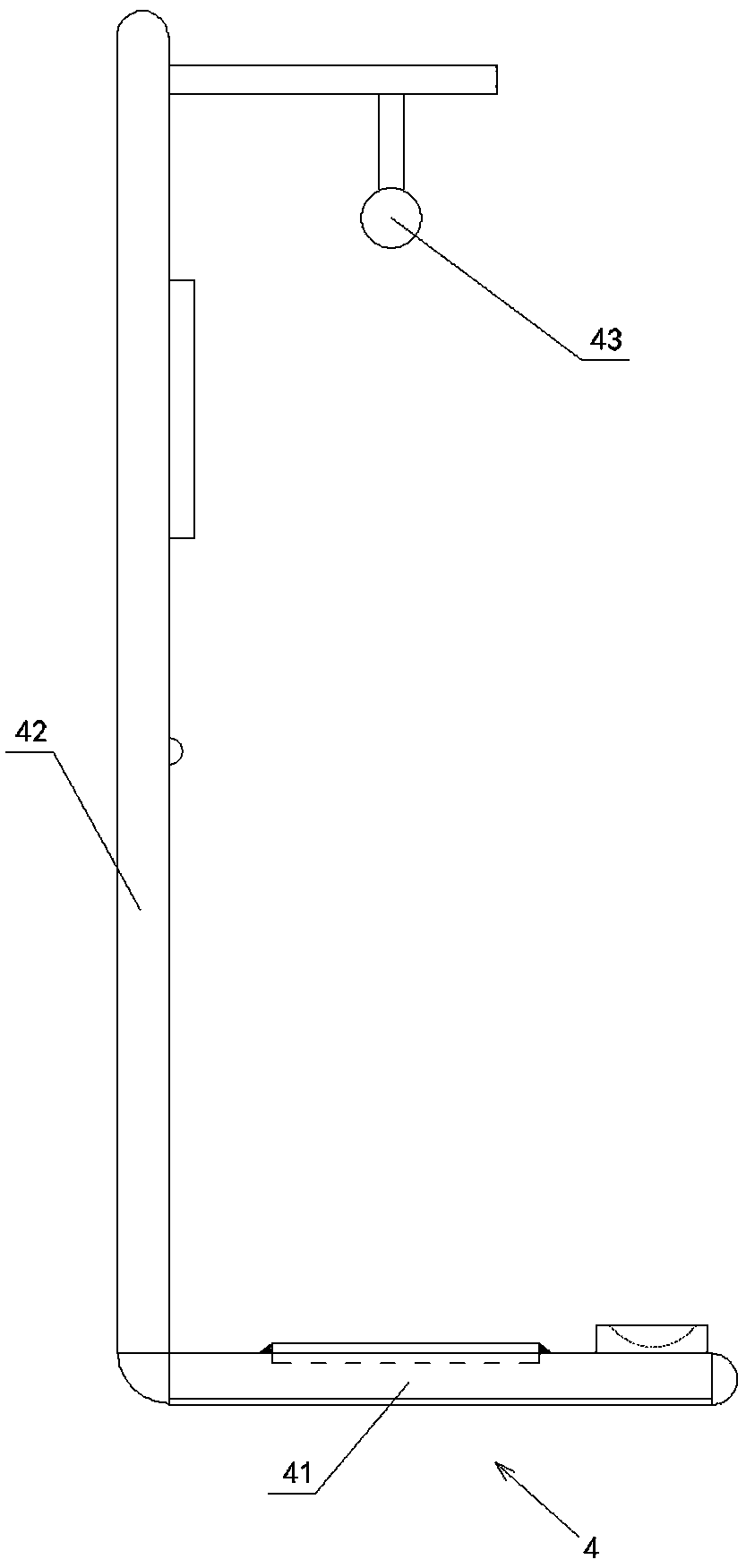

[0019] refer to figure 1 with image 3 . The manual water press with weight automatic sensing function includes a protective shell 21 detachably installed on the water outlet of the barreled water bucket 1 through the connector 20. The protective shell 21 is movable with a manual plug 22. The manual plug 22 can move up and down through the upper port of the protective housing 21, and also includes a support 4 matched with the barreled water bucket. The connected vertical rod 42 and the illuminating lamp 43 installed on the top of the vertical rod 42 . The lighting lamp 43 is an LED lamp, and the LED lamp is located directly above the bottled water bucket 1 . The design of the lighting lamp 43 is adopted to make the manual water press have a lighting function, so that when the light is not good, the user can turn on the lighting lamp to get water, which is convenient for use.

[0020] refer to figure 1 with image 3 . The vertical bar 42 is equipped with an infrared sens...

Embodiment 3

[0022] refer to figure 1 with figure 2 . The manual water press with weight automatic sensing function includes a protective shell 21 detachably installed on the water outlet of the barreled water bucket 1 through the connector 20. The protective shell 21 is movable with a manual plug 22. The manual plug 22 can move up and down through the upper port of the protective shell 21, and also includes a bracket 4 matched with the barreled water bucket 1, and the bracket 4 includes a horizontal base 41 for placing the barreled water bucket 1 and for receiving the manual plug. The water leakage of the water press outlet 23 is also installed on the leak receiving device 5 on the horizontal base 41, and the leak receiving device is positioned directly below the water outlet of the manual water press. Adopting the design of the leak-connecting device 5 facilitates people to collect the water accidentally leaked when receiving the water with a cup, so as to prevent the ground from gett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com