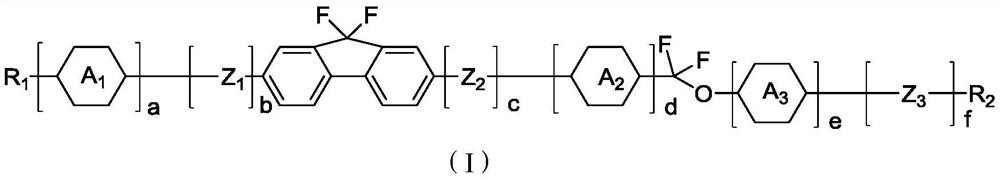

A kind of compound, liquid crystal composition and display device

A technology of liquid crystal composition and compound, which is applied in the field of compound, liquid crystal composition and display device, can solve problems such as fast response time, achieve wide liquid crystal state temperature range, good compatibility, and improve the effect of mutual solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

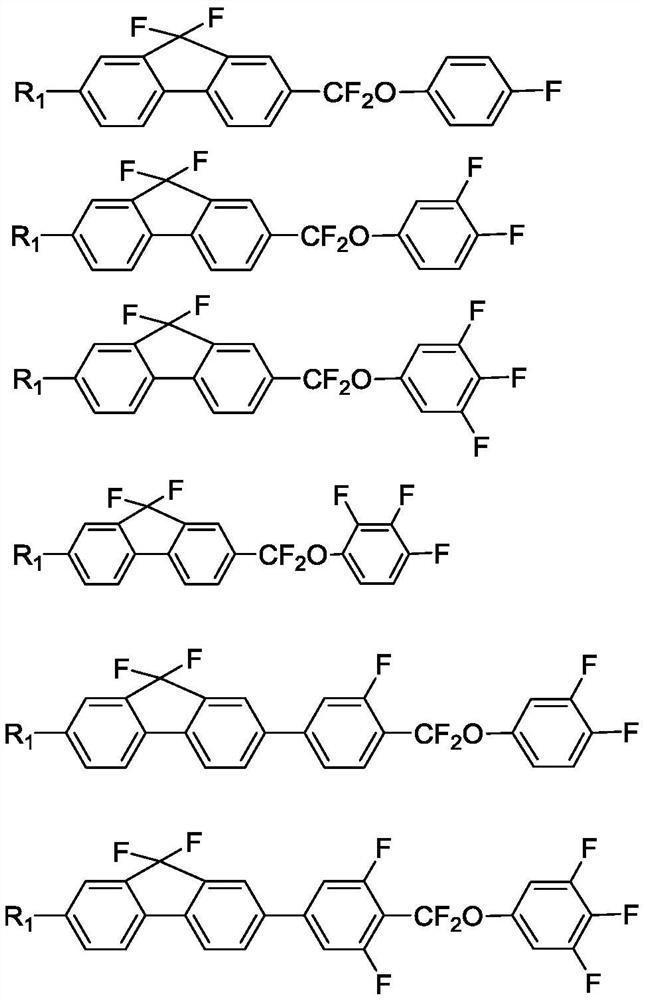

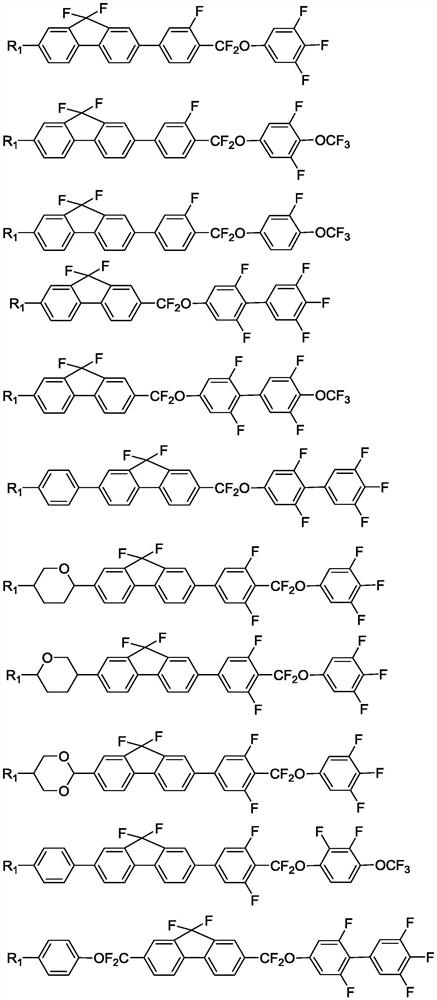

Method used

Image

Examples

preparation example Construction

[0154] The preparation method of the liquid crystal material is well known to those skilled in the art. For example, it can be: (1) heating, mixing and stirring various monomer liquid crystal compounds, and then filtering to obtain the liquid crystal material; (2) mixing various monomer liquid crystal compounds with a solvent Dissolving, then mixing evenly, and then extracting the solvent under vacuum conditions to obtain a liquid crystal material; (3) using oscillating mixing or ultrasonic mixing to mix various monomer liquid crystal compounds evenly, and then filtering to obtain a liquid crystal material. The ratio of various monomer liquid crystal materials is adjusted according to the specific display performance requirements. Mixed liquid crystal materials can be prepared by the above methods.

[0155] According to yet another aspect of the present invention, there is provided a display device comprising the above-mentioned liquid crystal composition.

[0156] The displa...

Embodiment 1

[0170] Monomer and components thereof in embodiment 1 and comparative example 1 are as shown in table 1:

[0171] Table 1

[0172]

[0173]

[0174] A series of performance tests were carried out on the liquid crystal compositions of Example 1 and Comparative Example 1, and the test results are shown in Table 1-1:

[0175] Table 1-1

[0176] Performance parameters Example 1 Comparative example 1 Cp(°C) 75.2 73.1 Δn 0.119 0.115 Δε 2.5 2.0 gamma 1 61 67

[0177] According to the test results of Table 1-1, it can be seen that the compound shown in formula (I) of the present invention was added in Example 1, compared with Comparative Example 1 in which the compound shown in formula (I) of the present invention was not added, the liquid crystal combination The material has a higher clearing point, a higher optical anisotropy constant and an electrical anisotropy constant, and a lower rotational viscosity, and can be used in liquid ...

Embodiment 2

[0178] Monomer and components thereof in embodiment 2 and comparative example 2 are as shown in table 2:

[0179] Table 2

[0180]

[0181]

[0182] A series of performance tests were carried out on the liquid crystal compositions of Example 2 and Comparative Example 2, and the test results are shown in Table 2-1:

[0183] table 2-1

[0184] Performance parameters Example 2 Comparative example 2 Cp(°C) 81.2 75.4 Δn 0.098 0.090 Δε 2.5 2.0 gamma 1 58 72

[0185] According to the test results of Table 2-1, it can be seen that the compound shown in formula (I) of the present invention was added in Example 2, compared with Comparative Example 2 in which the compound shown in formula (I) of the present invention was not added, the liquid crystal combination The material has a higher clearing point, a higher optical anisotropy constant and an electrical anisotropy constant, and a lower rotational viscosity, and can be used in liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com