Workpiece welding seam search device

A workpiece and mounting seat technology is applied in the field of workpiece welding seam finding devices, which can solve the problems of inconvenience and inconvenience of non-destructive testing work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The core of the present invention is to provide a workpiece weld seam search device, so as to quickly and accurately find the weld seam, so as to facilitate subsequent non-destructive testing of the weld seam.

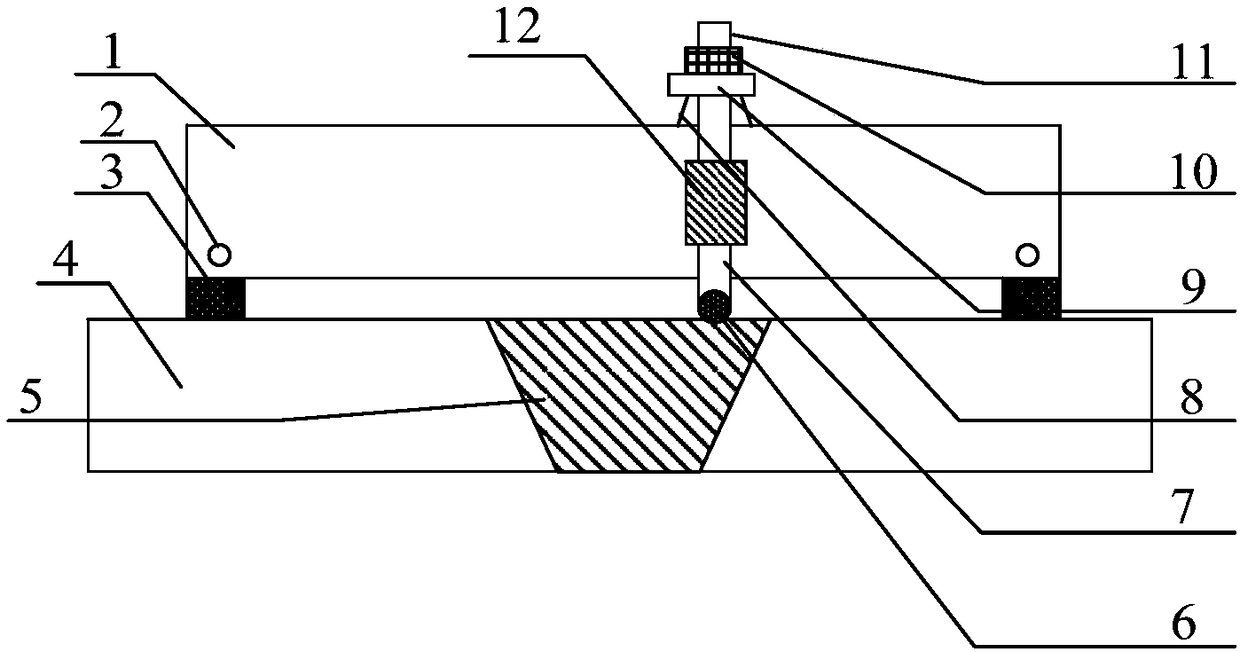

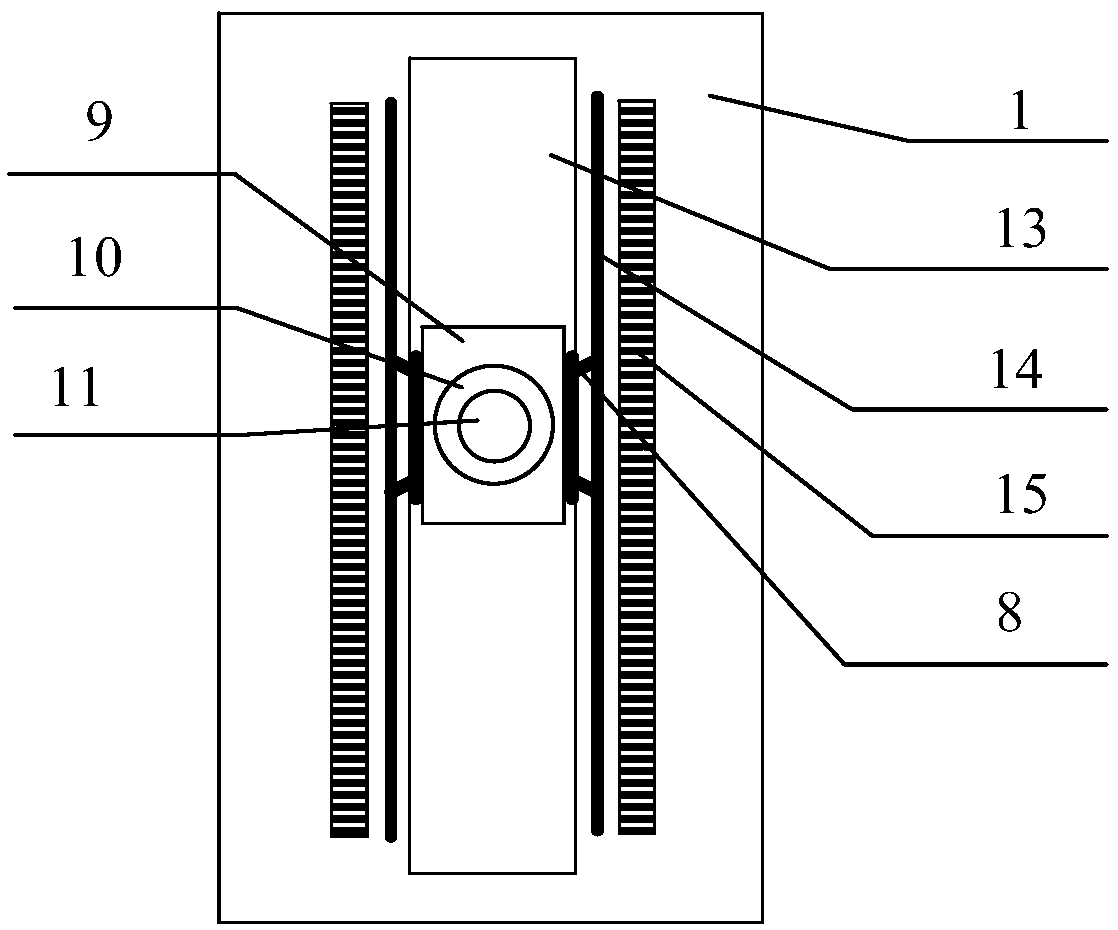

[0031] Please combine figure 1 and figure 2 , the workpiece weld seam search device disclosed in the present invention includes a main body plate 1, a sliding bracket, a thimble 11, a hardness test head, and a force nut 10. The main body plate 1 can be fixed on the workpiece, and the main body plate 1 is provided with a through body plate 1 top and bottom avoidance grooves, two guide grooves 14 are symmetrically distributed on both sides of the avoidance groove 13 on the main body plate 1 in the length direction, and the sliding bracket includes a mounting seat 9 located in the middle and symmetrically arranged on both sides of the mounting seat 9 Slide rail 8, slide rail 8 is embedded in the guide groove 14, to realize the sliding installation of the whole sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com