Dustproof plug for optical module

An optical module and dust-proof plug technology, applied in the field of optical communication, can solve the problems of increased cost and the inability of the optical module to be effectively protected, and achieve the effects of easy insertion and extraction, convenient use, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

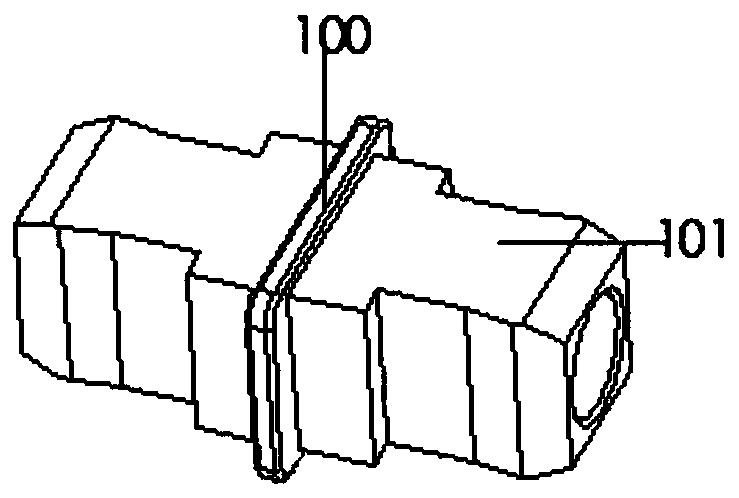

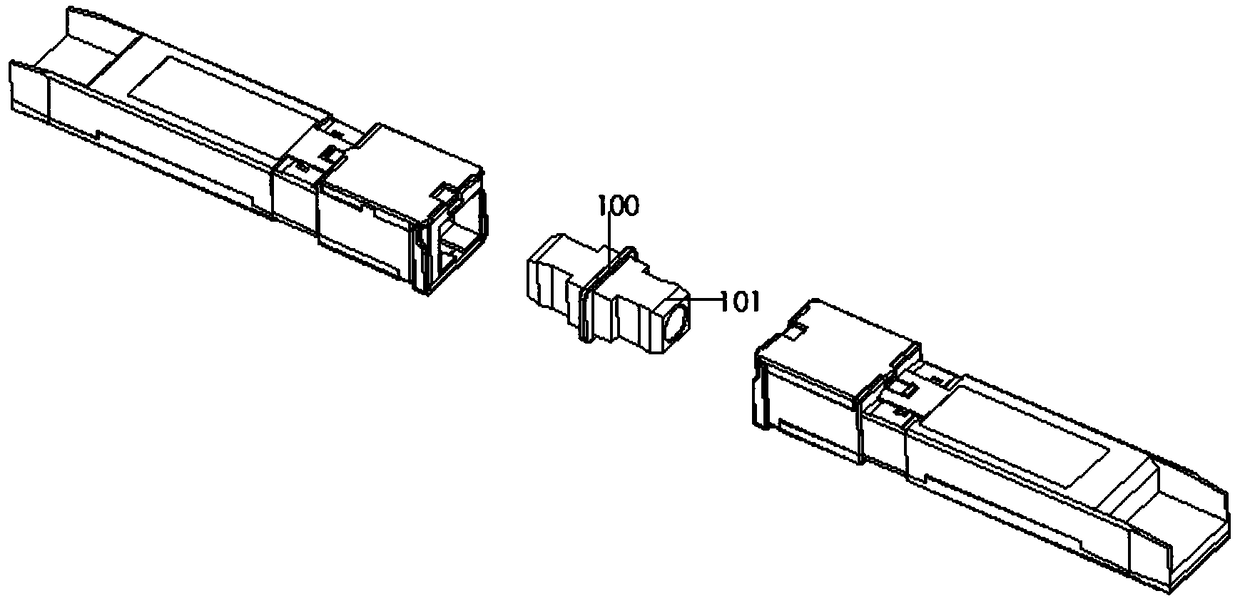

[0025] This embodiment provides a dust-proof plug for an optical module, which includes two insertion ends, and each insertion end is respectively used to be inserted into a port of an optical module to prevent dust.

[0026] Specifically, in this embodiment, the optical module dust plug also includes a rim 100, and two insertion ends are respectively arranged on both sides of the rim, and both insertion ends are insertion ends 101 suitable for SC port optical modules. .

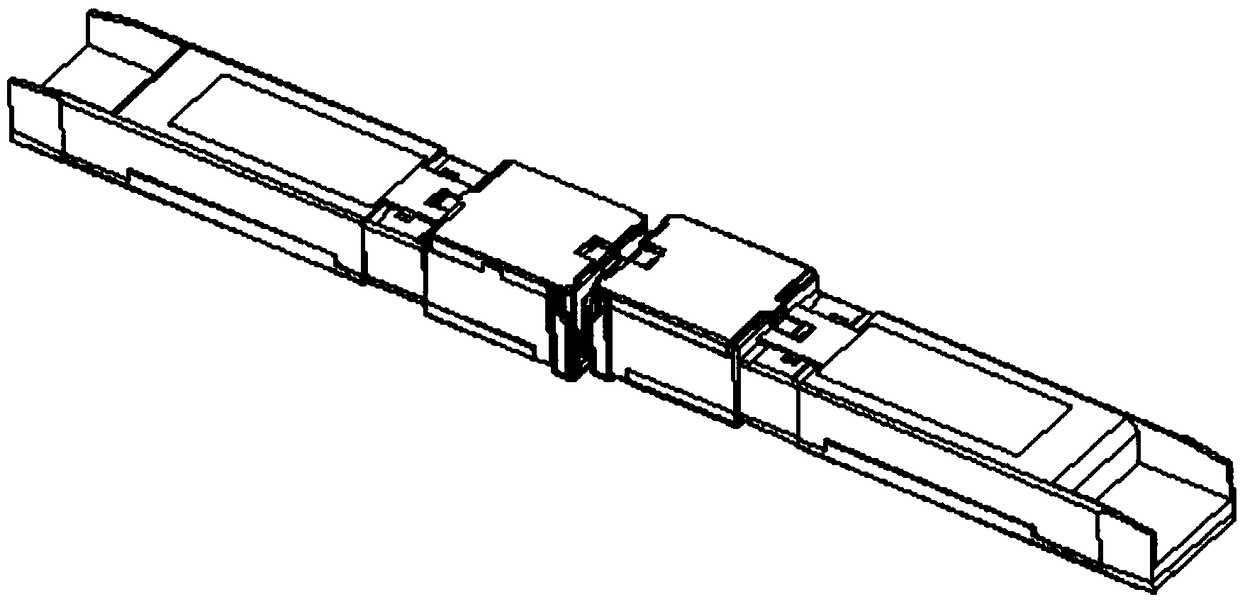

[0027] In this embodiment, both ends of the dustproof plug are insertion ends suitable for an optical module of an SC port; figure 1 , 2 As shown, the dustproof plug of the optical module can be inserted into an SC port optical module separately, or both ends can be inserted into the SC port optical module at the same time, which is convenient and practical. like figure 2 As shown, when in use, when the insertion end of the optical module is inserted into an SC port optical module, the left side of the r...

Embodiment 2

[0029] The main difference between this embodiment 2 and the above-mentioned embodiment 1 is that in this embodiment, there are two insertion ends, and both insertion ends are insertion ends 102 suitable for optical modules of LC ports, such as Figure 4 shown.

[0030] In this embodiment, the insertion ends are the insertion ends of the optical module suitable for the LC port; the dustproof plug for the optical module can be inserted into an LC port optical module separately, or both ends can be inserted into the LC port optical module at the same time, Convenient and practical.

Embodiment 3

[0032] The main difference between this embodiment 3 and the above-mentioned embodiment 1 is that in this embodiment, the two insertion ends are respectively the insertion end 101 suitable for the SC port optical module and the insertion end 102 suitable for the LC port optical module, such as Figure 5 shown.

[0033] In this embodiment, the optical module dustproof plug has two insertion ends, and the two insertion ends are respectively the insertion end suitable for the SC port optical module and the insertion end suitable for the LC port optical module; The insertion end of the port optical module is inserted into the SC port optical module, and the insertion end suitable for the LC port optical module is idle; the insertion end suitable for the LC port optical module can also be inserted into the LC port optical module, while the insertion end suitable for the SC port optical module The insertion end is idle, and one SC port optical module and one LC port optical module c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com