Pig hair residue cleaning device

A cleaning device and pig hair technology, which is applied to slaughtering devices, slaughtering accessories, heating and preserving meat/fish, etc., can solve problems such as unhealthy, high requirements, slipping, etc., and achieve the effect of easy, thorough and stable hair removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

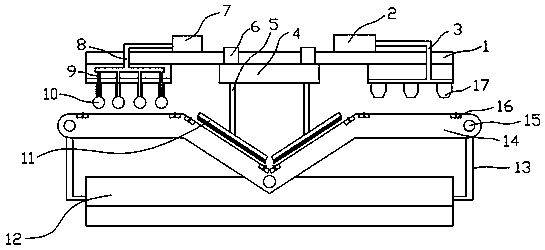

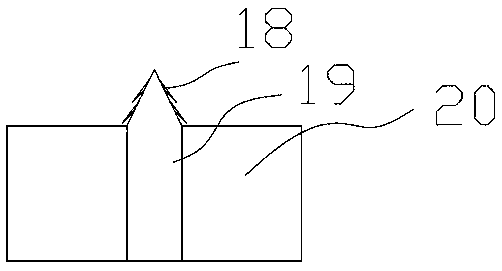

[0021] Such as Figure 1-5 As shown, the pig hair residue cleaning device includes a connecting plate 1, the upper left side of the connecting plate 1 is connected to the air pump 7, the right side of the air pump 7 is connected to the water pump 2, the air pump 7 is connected to the rolling device 10 through the air inlet pipe 8, and the water pump 2 is connected through the water inlet pipe 3 Connect the spray head 17, the conveyor belt 14 is arranged under the rolling device 10, and the fixing device 16 is arranged inside the conveyor belt 14, and the fixing device 16 includes a case 20, and a steel needle 19 is arranged inside the case 20, and the tip of the steel needle 19 is provided with an inverted Thorn 18. The device has simple structure, strong stability, time-saving and labor-saving, and complete hair removal. During the preliminary rolling and hair removal process, the air pump blows air to blow off the pig hair to avoid affecting the subsequent hair removal. Afte...

Embodiment 2

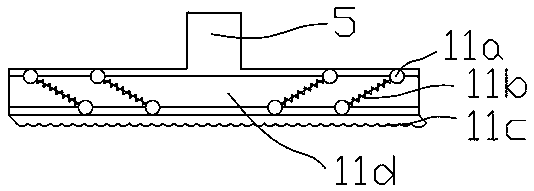

[0031] When the pig hair residue cleaning device of the present invention is actually used: the pork that needs to be depilated is put on the conveyor belt 14, the pork is fastened with the fixing device 16, and the rolling device 10 will roll and rub the pork to perform preliminary hair removal and degerming At the same time, the heat generated by friction will expand with heat and contract with cold, which is convenient for the shaver unit 11 to shave deeply. The air pump 7 operates to inflate the air collection chamber 10a. The hair is blown clean, the conveyor belt 14 transfers the pork to the bottom of the razor group 11, the motor 6 drives the razor group 11 to rotate, and the excess hair on the pork will be removed during the rotation, and after removal, the water pump 2 pumps water and puts the nozzle Inside the 17, the nozzle 17 sprays water to the pork for rinsing, and the sewage after rinsing will enter the sewage collection tank 12 to realize fast depilation.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com