A filter assembly for separating oil from compressed gas and compressor comprising such filter assembly

A filter assembly, a technology for compressing gas, used in membrane filters, dispersed particle filtration, liquid fuel engines, etc., can solve problems such as increasing the complexity and cost of liquid separation filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

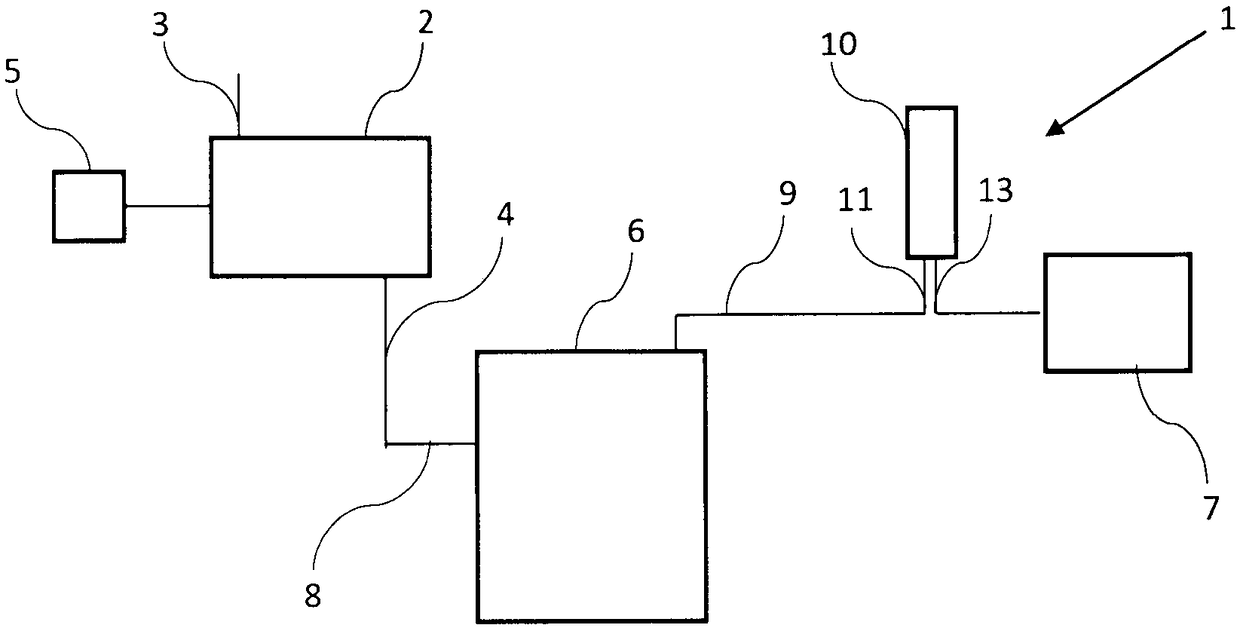

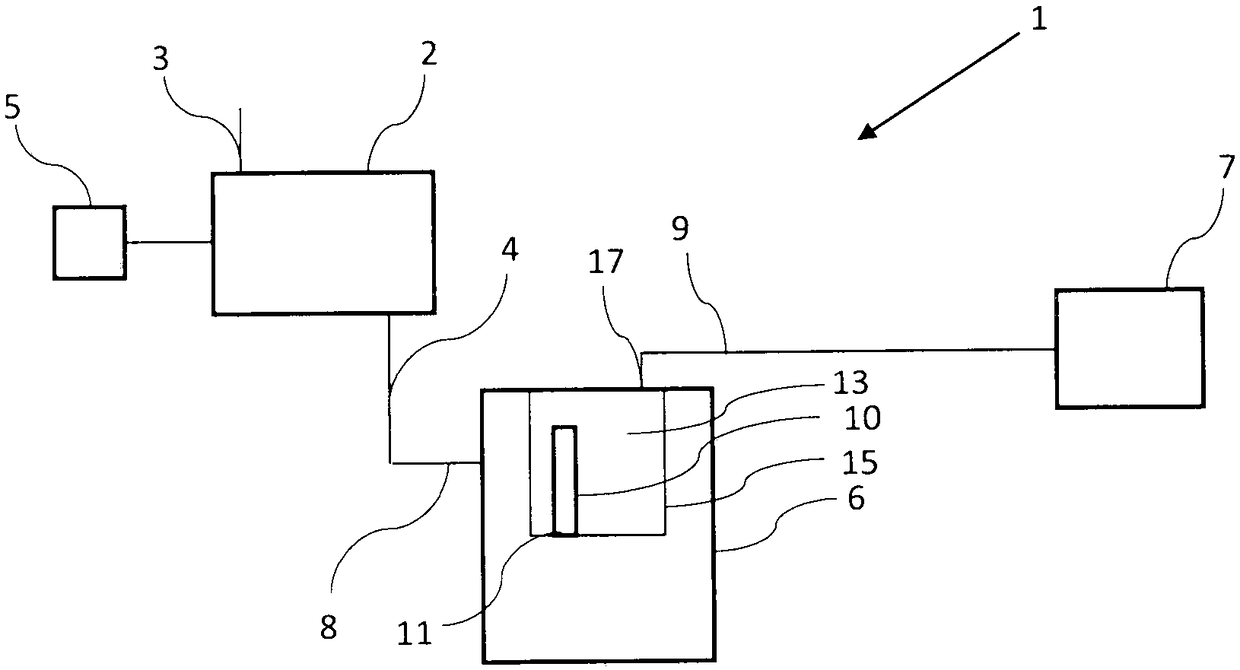

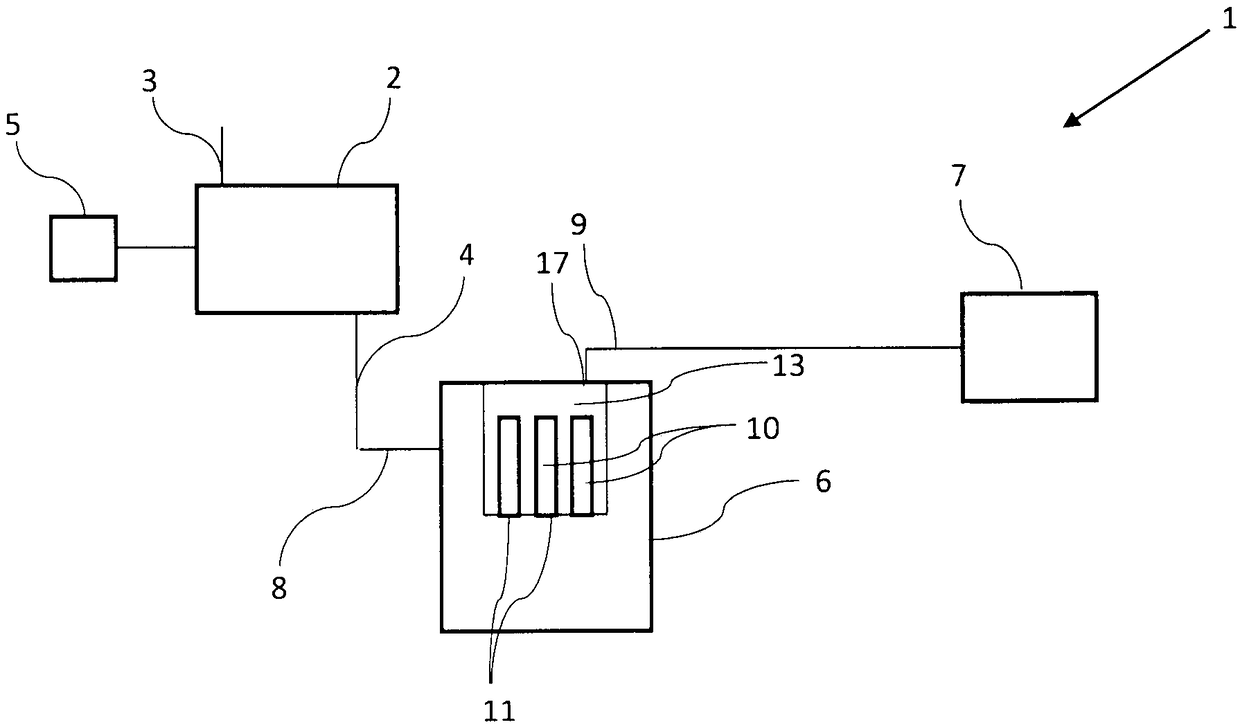

[0041] figure 1 A compressor 1 is shown comprising a compressor element 2 with a gas inlet 3 and a compressed gas outlet 4 . The compressor element 2 is driven by a constant speed motor or a variable speed motor 5 .

[0042] In the context of the present invention, compressor 1 should be understood as the entire compressor arrangement, including compressor element 2 , all typical connecting pipes and valves, the casing of compressor 1 and possibly a motor 5 driving compressor element 2 .

[0043] In the context of the present invention, a compressor element 2 is to be understood as a compressor element housing in which the compression process takes place by means of a rotor or by a reciprocating movement.

[0044] Furthermore, the compressor element 2 may be selected from the group consisting of screws, teeth, jaws, scrolls, rotating vanes, centrifuges, pistons.

[0045] back now figure 1 , the compressor 1 further comprises a separation vessel 6 arranged on the compressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com