Hydraulic rock drill and impactor and flow equalizing valve for the rock drill

A technology of flow equalizing valve and impactor, applied in the field of impactor, equalizing valve and hydraulic rock drill, can solve the problems of inefficiency, lack of actual efficiency, reduced energy utilization rate, etc., to eliminate rotary motion, eliminate inefficiency loss, The effect of improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

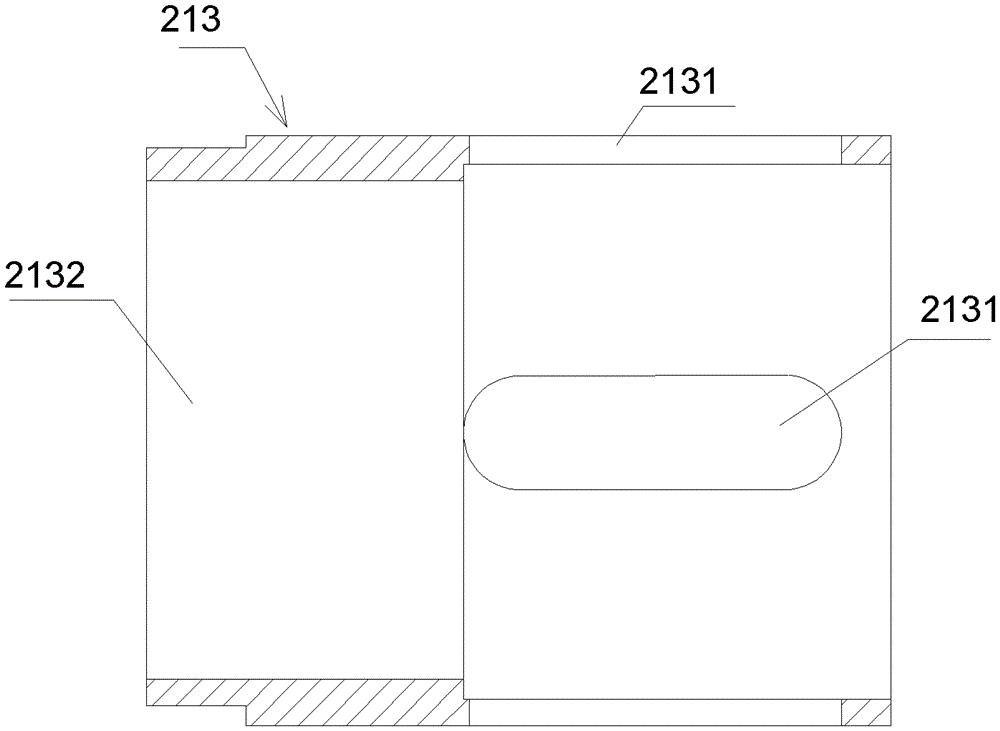

[0025] Please refer to figure 2 , the present invention is a flow equalizing valve 213 for hydraulic rock drill impactor, including a valve body for installation in the impact oil cylinder; There is a through flow equalizing hole 2131, which communicates with the valve cavity 2132, and the center line of the flow equalizing hole 2131 is perpendicular to the center line of the valve cavity 2132, so as to ensure that the pressure flow line in the oil inlet direction is consistent with that of the impacting piston. Centerlines are perpendicular to each other.

[0026] In order to more effectively counteract the tangential force of the fluid on the impact piston, the number of equalizing valves 213 is preferably an even number, and are evenly and symmetrically distributed on the valve body around the centerline of the valve cavity 2132 . In this example, the flow equalizing valve 213 is designed to be larger in volume, and the equalizing hole 2131 is in the shape of a long groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com