Limiting device for hammer mill and facilitating hammer replacement

A hammer mill, a technology that is easy to replace, applied in the direction of grain processing, etc., can solve the problems of no specific guidance plan, regular replacement, and more materials, so as to save time and effort for hammer replacement, reduce workload, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

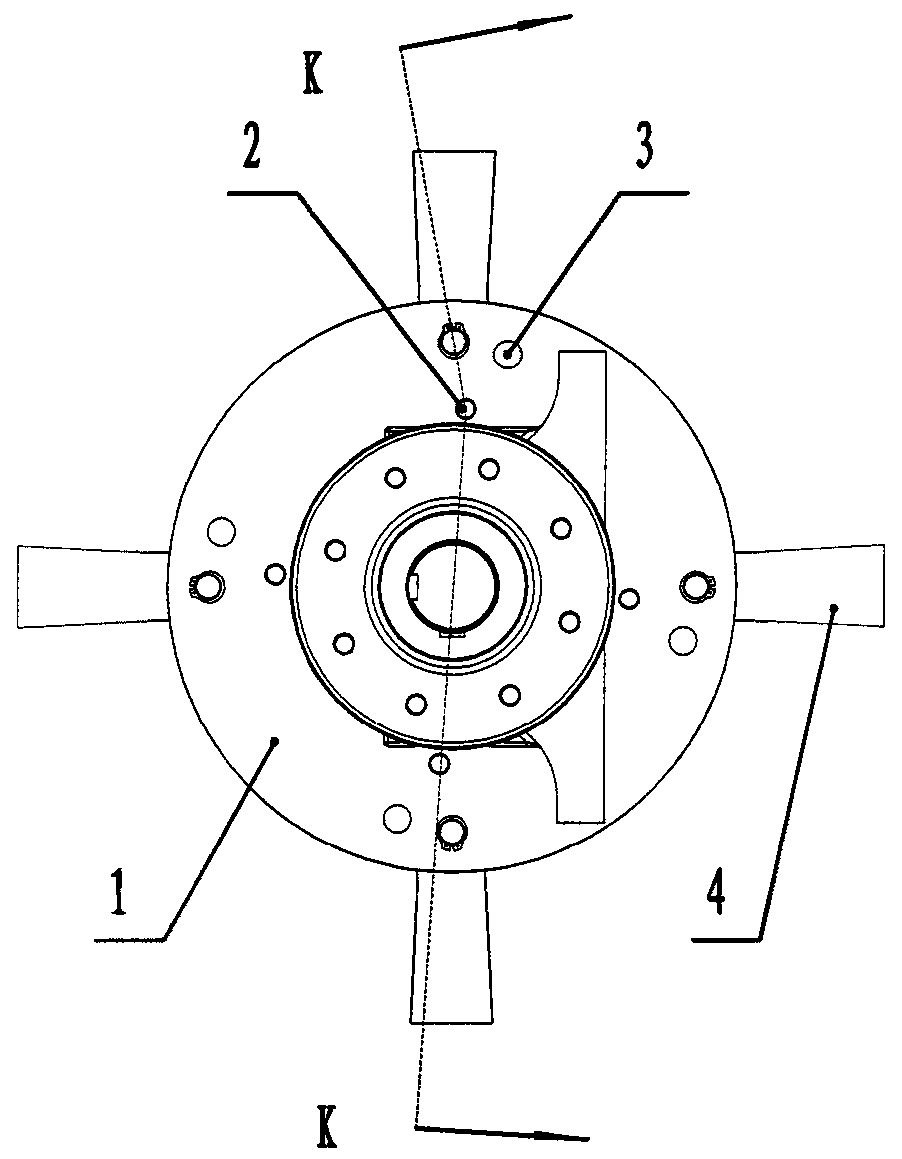

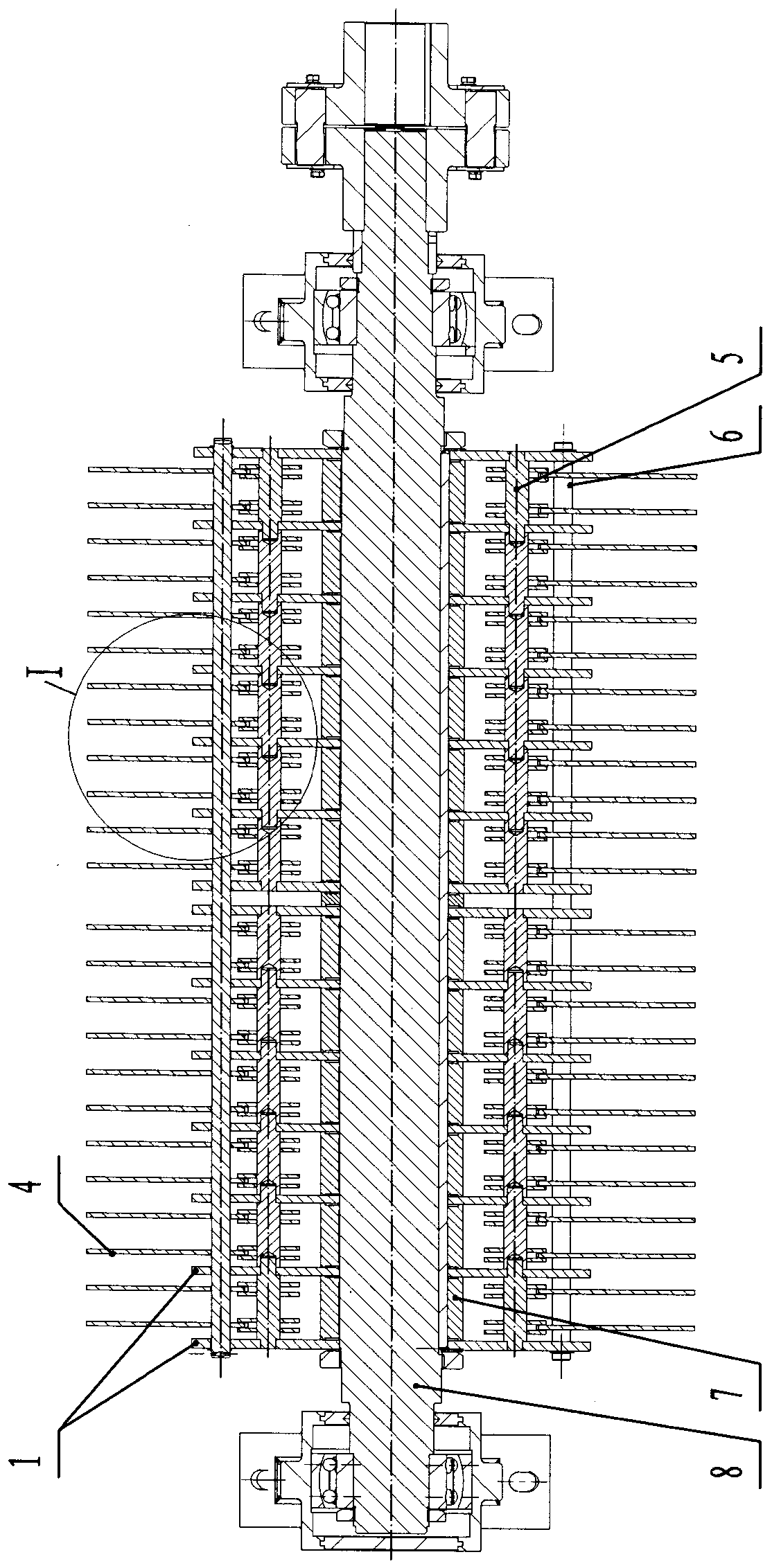

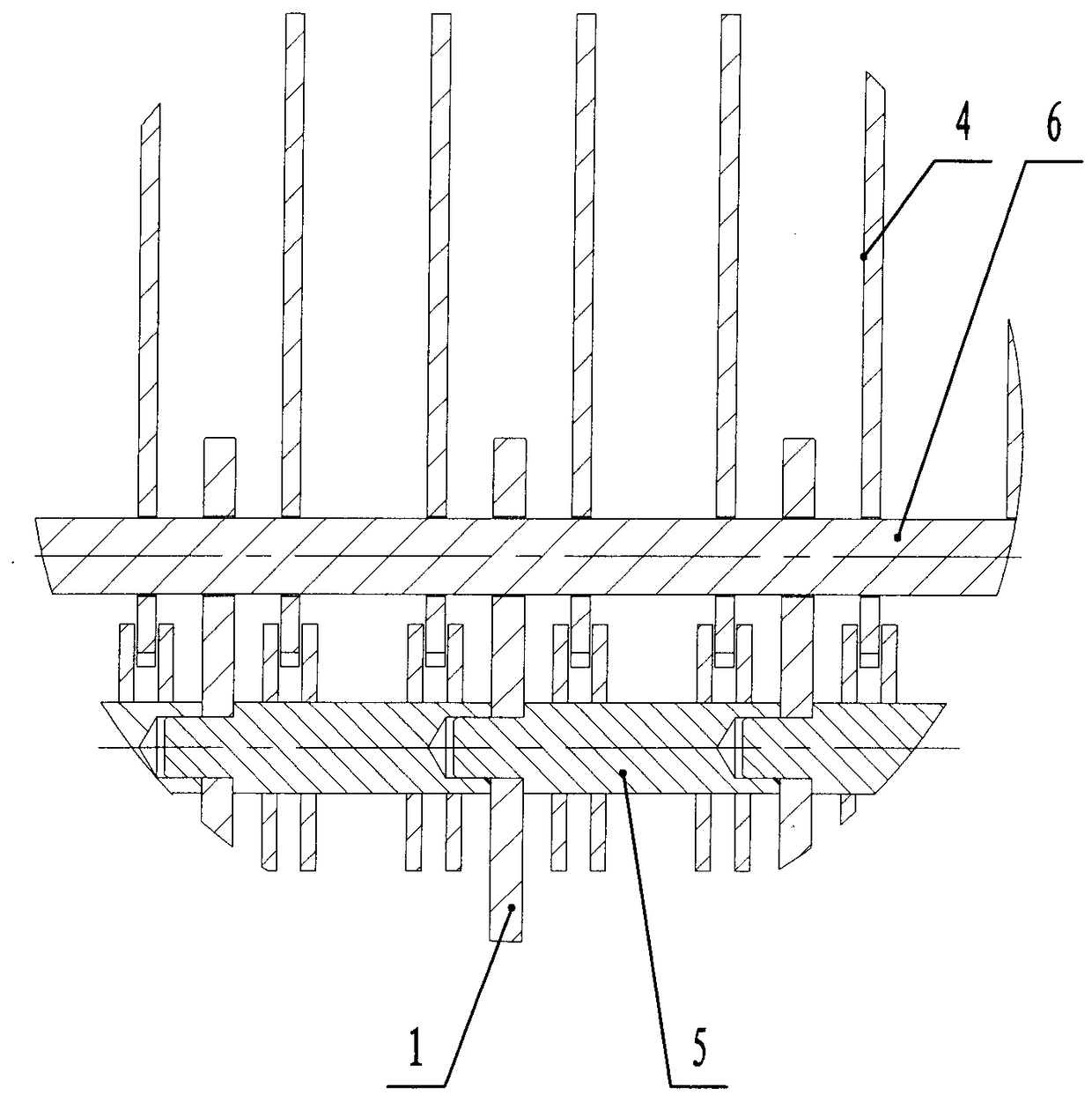

[0028] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the stopper for convenient replacement of the hammer for the hammer mill of the present invention has a plurality of hammer holders 1, a plurality of hammer shafts 6, a plurality of hammers 4, and a plurality of hammers are carried out. The limiting body 5 of the limit. Each hammer frame 1 has a group of hammer shaft holes (a group of hammer shaft holes) that make the hammer shaft in one installation position, and each group of hammer shaft holes on each hammer frame has a set of hammer shaft holes for A plurality of hammer shaft holes 3 corresponding to the plurality of hammer shafts passing through the plurality of hammer shafts, the number of the plurality of hammer shaft holes in each group of hammer shaft holes is the same as the number of hammer shafts , the projections of the transverse centerlines of the plurality of hammer axis holes 3 i...

Embodiment 2

[0034] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the stopper for convenient replacement of the hammer for the hammer mill of the present invention has a plurality of hammer holders 1, a plurality of hammer shafts 6, a plurality of hammers 4, and a plurality of hammers are carried out. The limiting body 5 of the limit. Each hammer frame 1 has two groups of hammer shaft holes (two groups of hammer shaft holes) that make the hammer shafts in two (different) installation positions respectively. Each group of hammers on each hammer frame The shaft hole has a plurality of hammer shaft holes 3 corresponding to the plurality of hammer shafts passing through the hammer shafts, and the number of the plurality of hammer shaft holes in each group of hammer shaft holes is the same as that of the hammer shaft. The number of film shafts is the same, and the projections of the transverse centerlines of the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com