Clamp for numerical control machine tool

A technology of CNC machine tools and fixtures, applied in the field of CNC machine tools, can solve the problems of prolonged processing time, waste products, trouble and inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

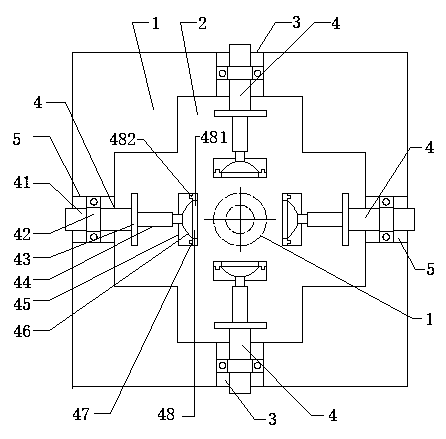

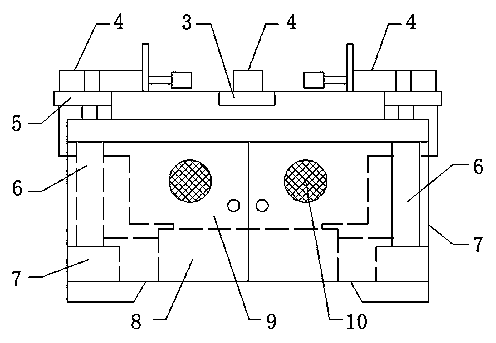

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as Figure 1-Figure 2 As shown, a kind of fixture for numerically controlled machine tool of the present invention, it comprises fixture body, and this fixture body comprises work box 7, and the top surface of this work box 7 is work platform 1, and the shape of described work platform 1 is square, The left and right sides of the working platform 1 are drilled with circular through holes; the working platform 1 is provided with a cross-shaped processing platform 2;

[0022] In the middle of the front and rear ends of the cross-shaped processing platform 2, a square fixed pallet 3 is installed, which is fixed with screws; the middle part of the work box 7 is provided with an air pump 8, and the left and right sides of the work box 7 are correspondingly provided with square pallets 7. Vertical cylinders 6 are installed on the two square pallets 7 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com