Double-roller gluing device

A technology for gluing and gluing rollers, applied in the field of mechanical processing, can solve the problems of poor gluing effect, difficult operation, complicated structure, etc., and achieve the effect of improving gluing effect and gluing uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

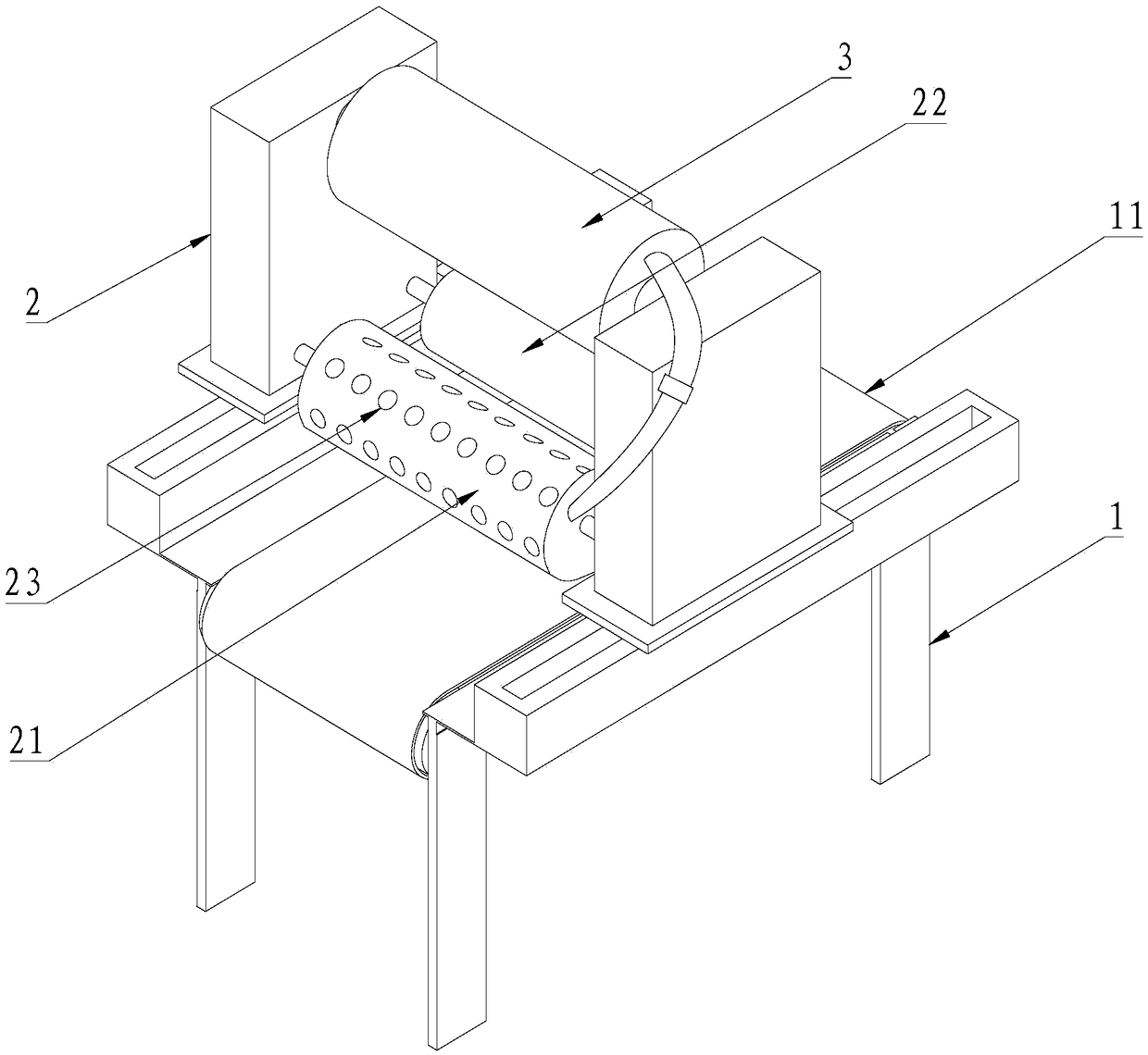

[0033] Please refer to figure 1 , Embodiment 1 of the present invention is: a double-roller gluing device, including a machine 1 and a gluing mechanism 2 installed on the machine 1;

[0034] The gluing mechanism 2 includes a first gluing roller 21 and a second gluing roller 22 placed horizontally on the machine 1, and the first gluing roller 21 and the second gluing roller 22 are all arranged horizontally , the first upper rubber roller 21 and the second upper rubber roller 22 are parallel to each other and arranged front and rear along the feeding direction of the machine 1, the first upper rubber roller 21 includes an inner cavity for storing rubber materials and has a surface The through hole 23 that runs through to the inner cavity of the first top rubber roller 21, the distance between the adjacent through holes 23 on the same generatrix of the first top rubber roller 21 is equal to the diameter of the through hole 23 double.

Embodiment 2

[0035] Please refer to figure 1 , Embodiment 2 of the present invention is: a double-roller gluing device, comprising a machine 1 and a gluing mechanism 2 installed on the machine 1;

[0036] The gluing mechanism 2 includes a first gluing roller 21 and a second gluing roller 22 placed horizontally on the machine 1, and the first gluing roller 21 and the second gluing roller 22 are cylindrical , the first upper rubber roller 21 and the second upper rubber roller 22 are all arranged horizontally, the first upper rubber roller 21 and the second upper rubber roller 22 are parallel to each other and arranged front and rear along the feeding direction of the machine 1, The first top rubber roller 21 includes a cavity for storing rubber and the surface has a through hole 23 penetrating to the cavity of the first top rubber roller 21. The through hole 23 is circular in shape and is located at the first top rubber roller. The distance between the centers of the adjacent through-holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com