Water diversion tunnel structure

A diversion tunnel and drainage tunnel technology, applied in water conservancy projects, hydropower, hydropower stations, etc., can solve problems such as steep and shallow slopes at the outlet of non-pressure diversion tunnels that cannot meet the submerged depth of water intakes, and difficult layout of diversion tunnels , to achieve the effect of avoiding unfavorable terrain and geological conditions, superior hydraulic conditions, and reducing the amount of seepage water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

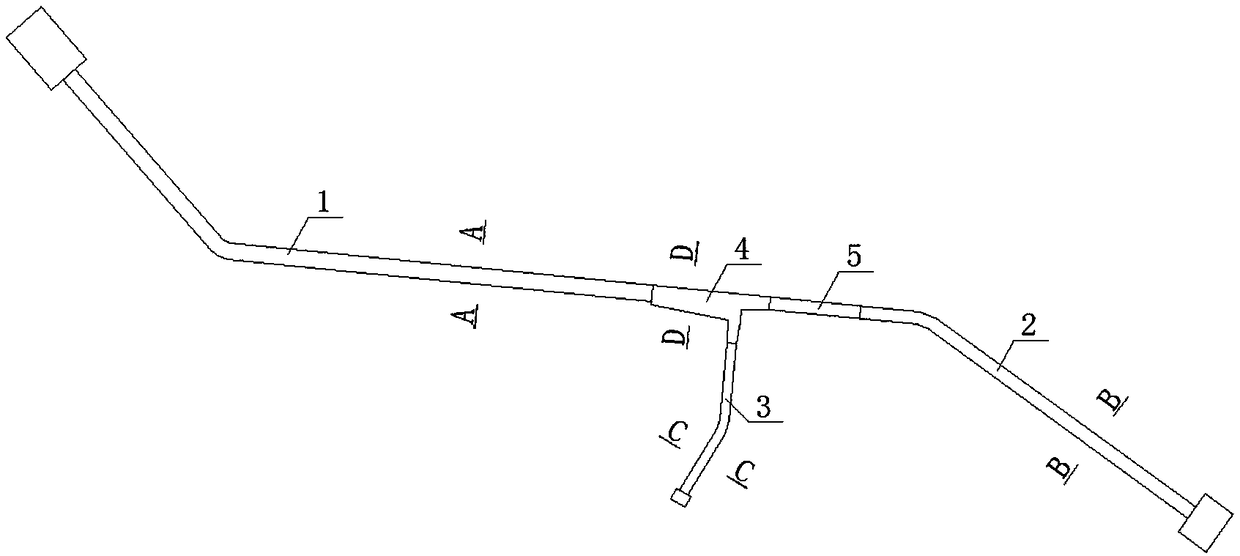

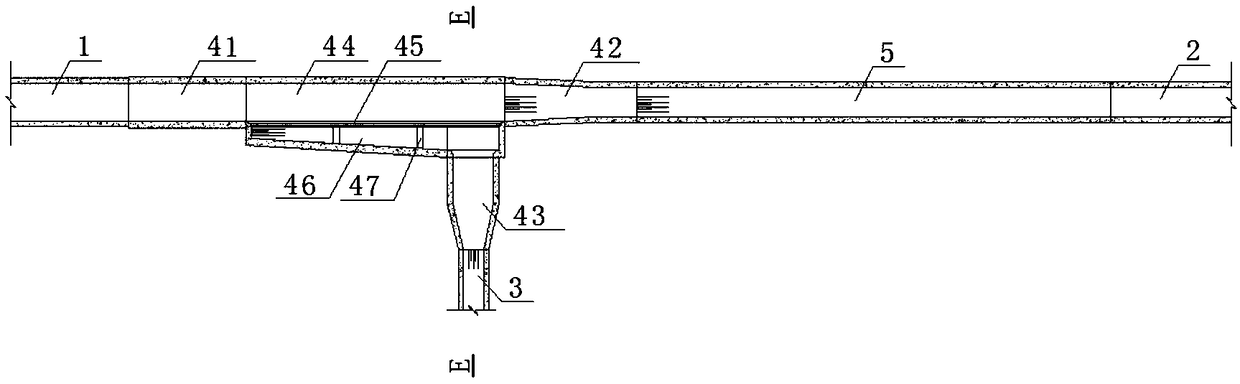

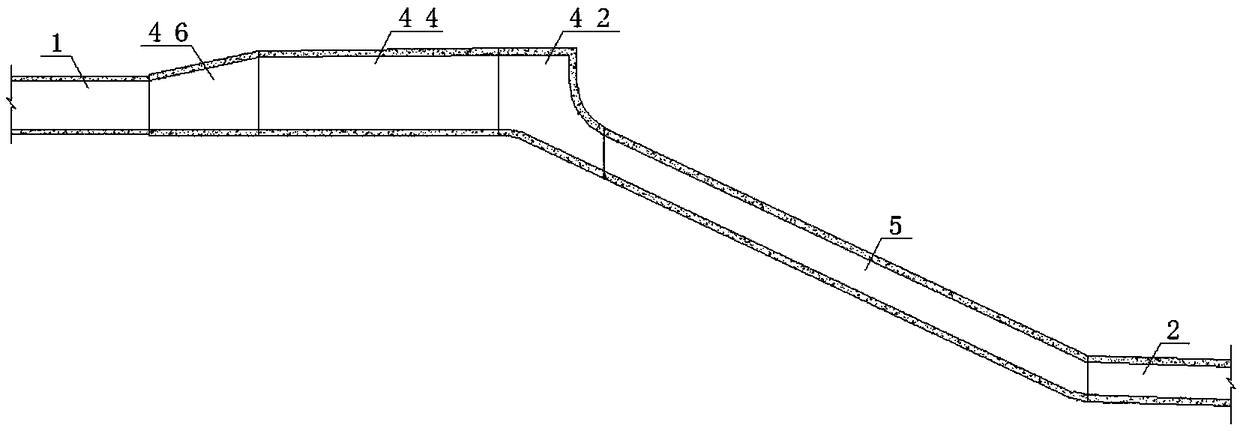

[0031] Such as Figure 1-8 As shown, a diversion tunnel structure includes a non-pressure tunnel 1, a pressure tunnel 2, and a drainage tunnel 3; , in order to meet the pressure water flow requirements of the hydropower station, the downstream of the regulating pool 4 is provided with an inclined well 5 to make the water flow transition from pressureless to pressurized. The surge well or the pressure steel pipe is connected; the regulating tank 4 includes an upstream transition section 41, a downstream transition section 42, a side transition section 43 and an intermediate section, one end of the middle section is connected with the upstream transition section 41, and the other end is connected with the downstream transition section 42 connection, one side of the middle section is connected with the side transition section 43; one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com