Safety box with automatic fire extinguishing function

A technology for safes and cabinets, which is applied in the field of safes, can solve the problems that safes enter the cabinet without any countermeasures, and cannot provide protection, so as to timely extinguish the fire, improve cost and applicability, The effect of good control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

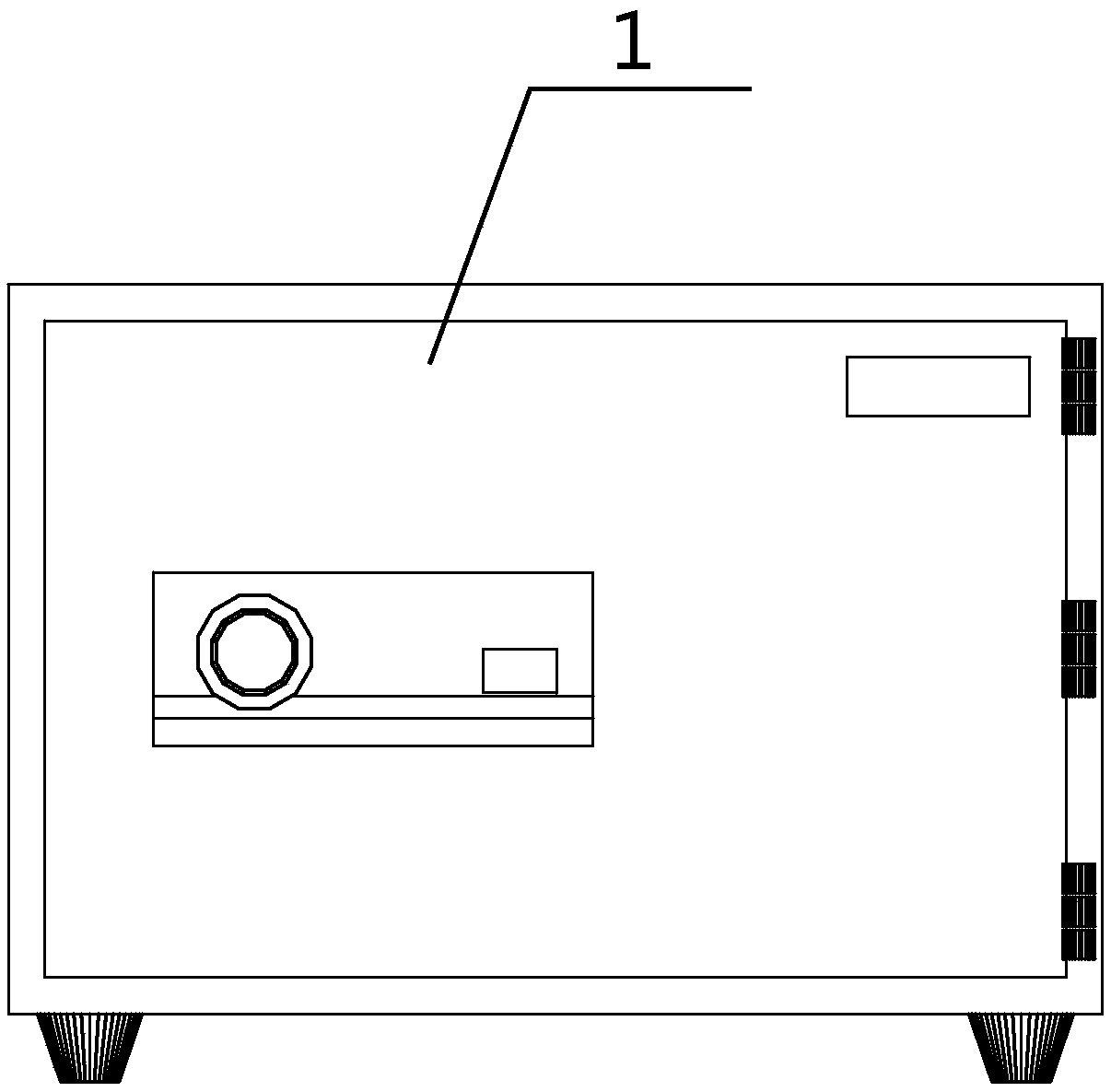

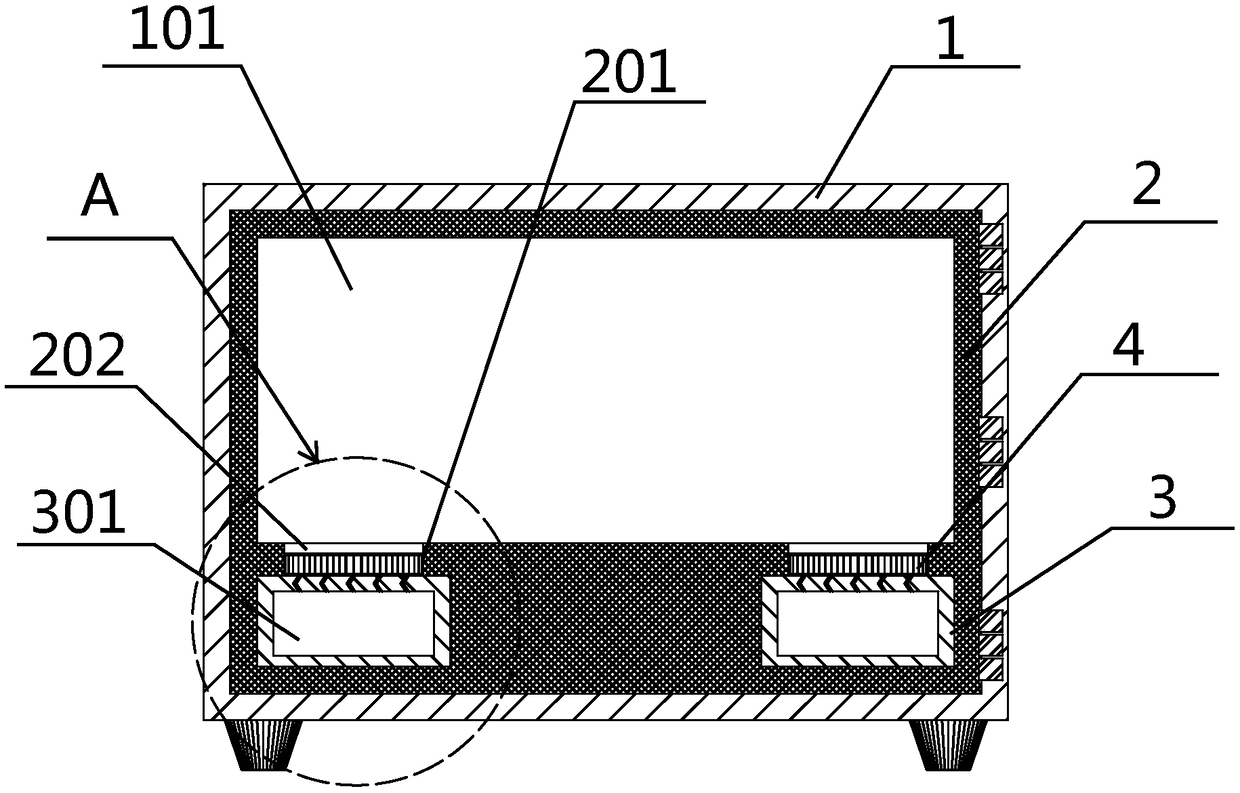

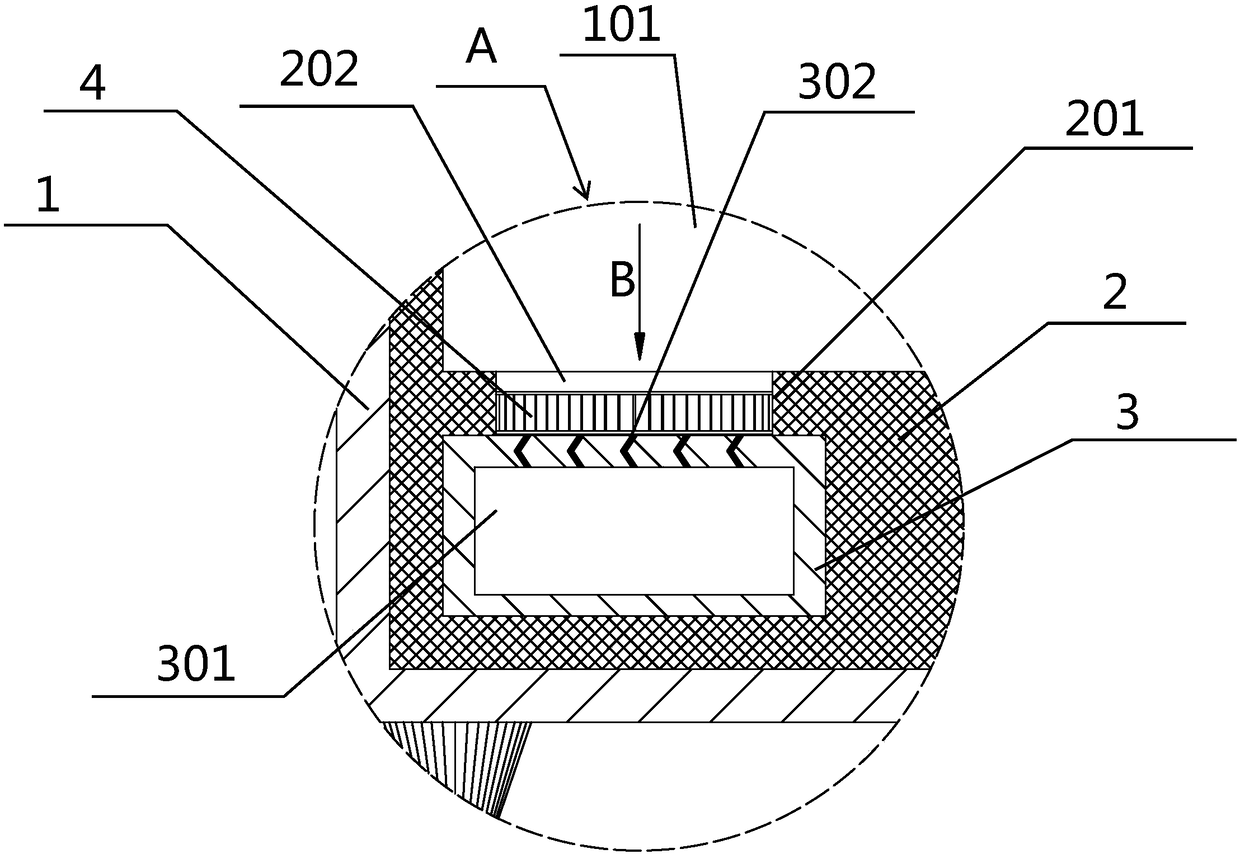

[0033] Such as figure 1 and figure 2 The shown self-extinguishing safe includes a main body 1 and a lining 2. The main body 1 includes a cabinet door, a cabinet body, a safety lock and cabinet feet. Cavity 101, the inner cavity 101 is used to store articles, and two liquid storage chambers 3 are also provided in the inner lining 2 of the bottom part of the cabinet body. The liquid storage chambers 3 have high compressive and flexural strength and have It is made of high-strength calcium silicate heat insulating material with good heat insulation performance. The liquid storage chamber 3 is a hollow structure, forming a liquid storage chamber 301. There is liquid carbon dioxide with a maximum capacity of about 4 / 5 in the liquid storage chamber 301, such as image 3 As shown, the upper end of the liquid storage chamber 3 is provided with several small through holes 302 filled with glass glue. The frictional force generated when the glass glue filled and blocked in the small t...

Embodiment 2

[0035] Such as figure 1 and figure 2 The shown self-extinguishing safe includes a main body 1 and a lining 2. The main body 1 includes a cabinet door, a cabinet body, a safety lock and cabinet feet. Cavity 101, the inner cavity 101 is used to store articles, and two liquid storage chambers 3 are also provided in the inner lining 2 of the bottom part of the cabinet body. The liquid storage chambers 3 have high compressive and flexural strength and have It is made of high-strength calcium silicate heat insulating material with good thermal insulation performance. The liquid storage chamber 3 is a hollow structure, forming a liquid storage chamber 301. There is liquid carbon dioxide with a maximum capacity of about 3 / 4 in the liquid storage chamber 301, such as image 3 As shown, the upper end of the liquid storage chamber 3 is provided with several small through-holes 302 filled with resin. The frictional force generated when the resin filled and blocked in the small through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com