Sliding bearing assembly of magnetic pump and magnetic pump

A technology of sliding bearings and magnetic pumps, which is applied to pump components, parts of pumping devices for elastic fluids, pumps, etc., can solve problems affecting the running stability of the shaft system, damage to sliding bearings, etc., and achieve stable installation and improved Stability, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

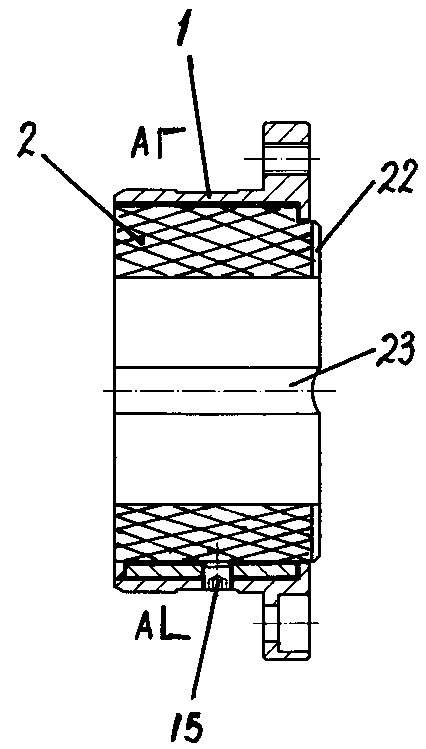

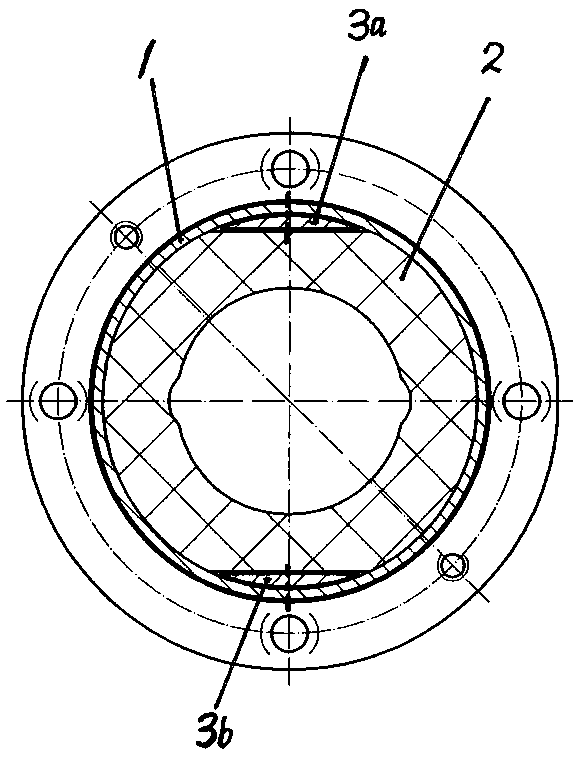

[0020] The magnetic pump sliding bearing assembly of the present invention is composed of a bearing seat 1, a sliding bearing 2, and anti-rotation key plates 3a and 3b;

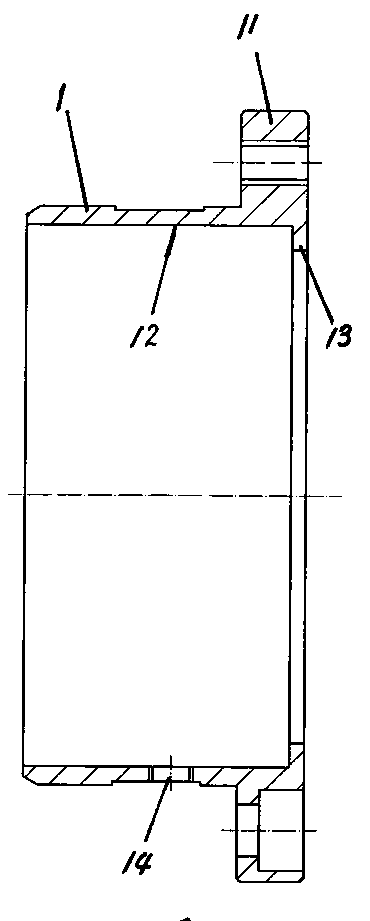

[0021] The bearing seat 1 is provided with an end flange 11, and an inner flange 13 of the mouth is provided on the port of the inner hole 12 of the bearing seat 1;

[0022] On the outer circle 20 of the sliding bearing 2, circular planes 21a, 21b are arranged symmetrically, on the outer end of the sliding bearing 2, an outer stop 24 is arranged, and on the outer end surface 25 of the sliding bearing 2, radial lubrication guide grooves 22 are distributed. Axial lubricating liquid guiding grooves 23 are distributed in the inner hole of the sliding bearing 2, and the outer circle 20 of the sliding bearing 2 is installed in cooperation with the inner hole of the bearing housing 1, and the circles formed symmetrically on the outer circle 20 of the sliding bearing 2 On the planes 21a and 21b, the anti-rotation key...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com