Auxiliary spring device used for hydraulic bushing

An auxiliary spring, hydraulic bushing technology, applied in the direction of spring, spring/shock absorber, shock absorber-spring combination, etc., can solve the problem of limited range of stiffness and damping adjustment, and achieve the effect of enhancing variable stiffness, good Vibration reduction effect, effect of improving damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing. It should be noted that the terms "axial" and "radial" in this article refer to figure 1 in the horizontal and vertical directions.

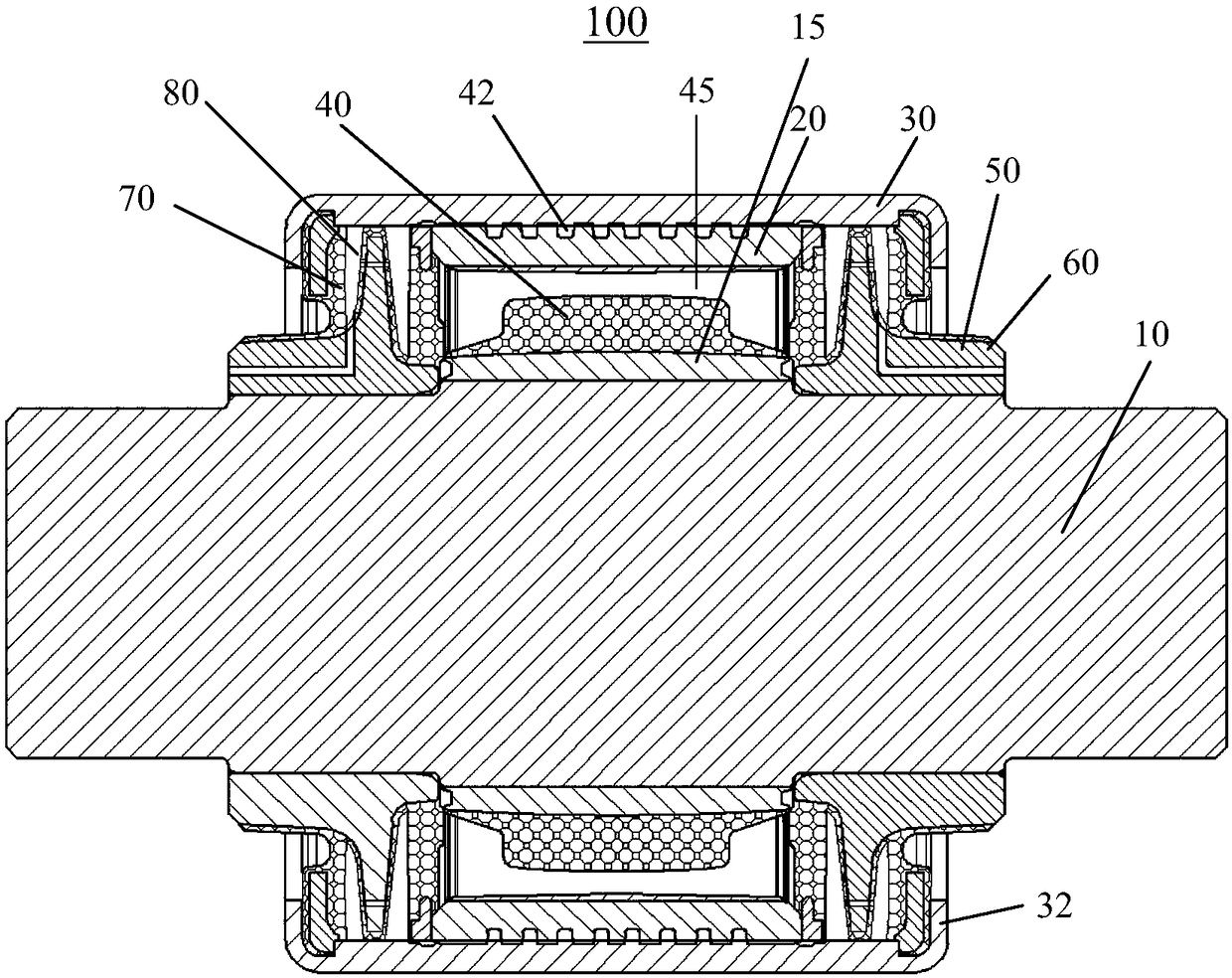

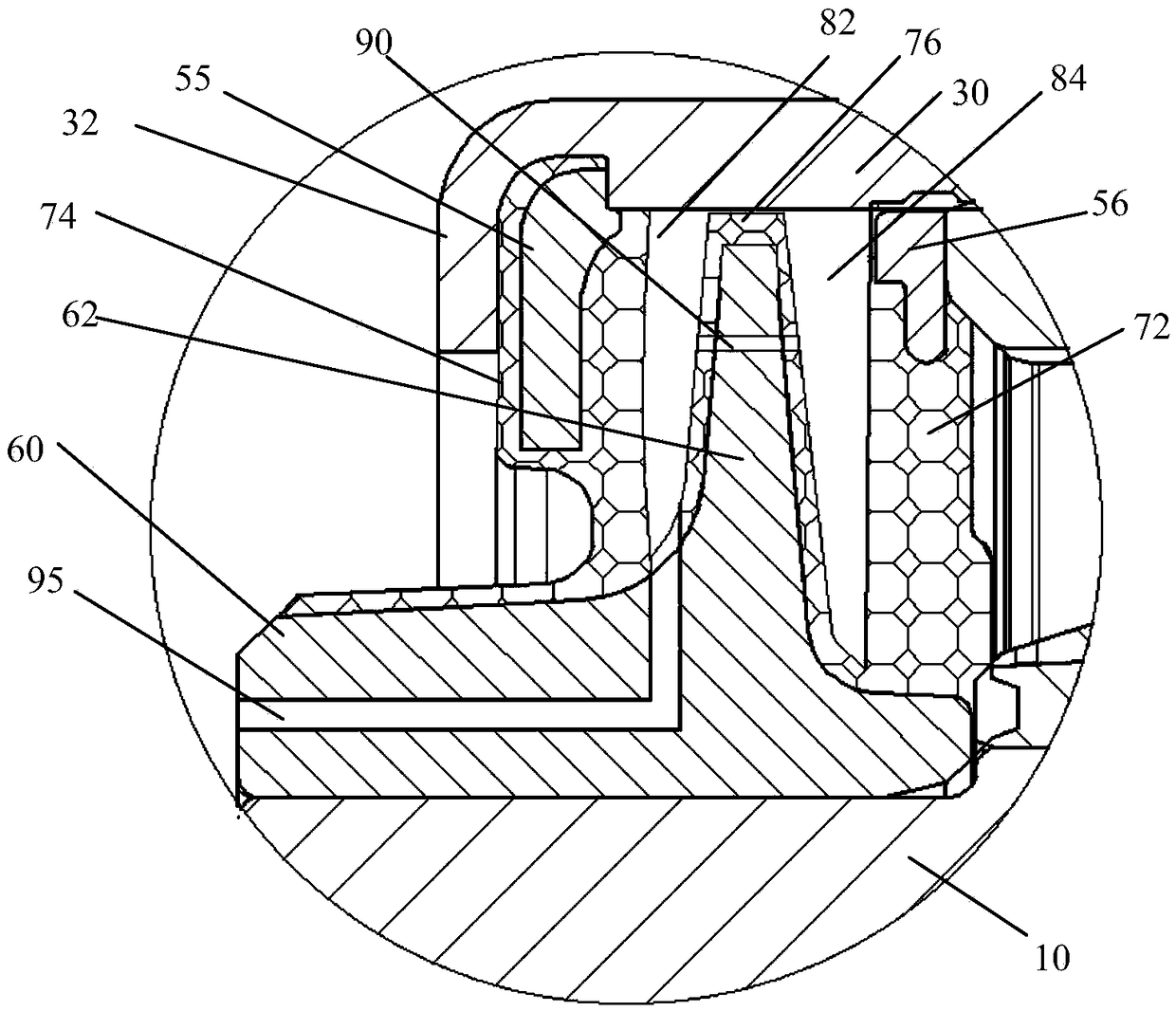

[0024] figure 1 A hydraulic bushing 100 including an auxiliary spring arrangement 50 according to an embodiment of the invention is schematically shown. like figure 1 As shown, the hydraulic bushing 100 includes a mandrel 10 , a flow channel body 20 arranged radially outside the mandrel 10 , and a casing 30 sleeved on the radially outside of the flow channel body 20 in a compression manner. The runner body 20 is generally configured in the form of a sleeve part. The mandrel 10 is usually a preform, and in figure 1 In the exemplary embodiment shown, it is configured in the form of a stepped shaft. The two ends of the mandrel 10 can be connected with the bogie of the railway train, for example, and the outer casing 30 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com