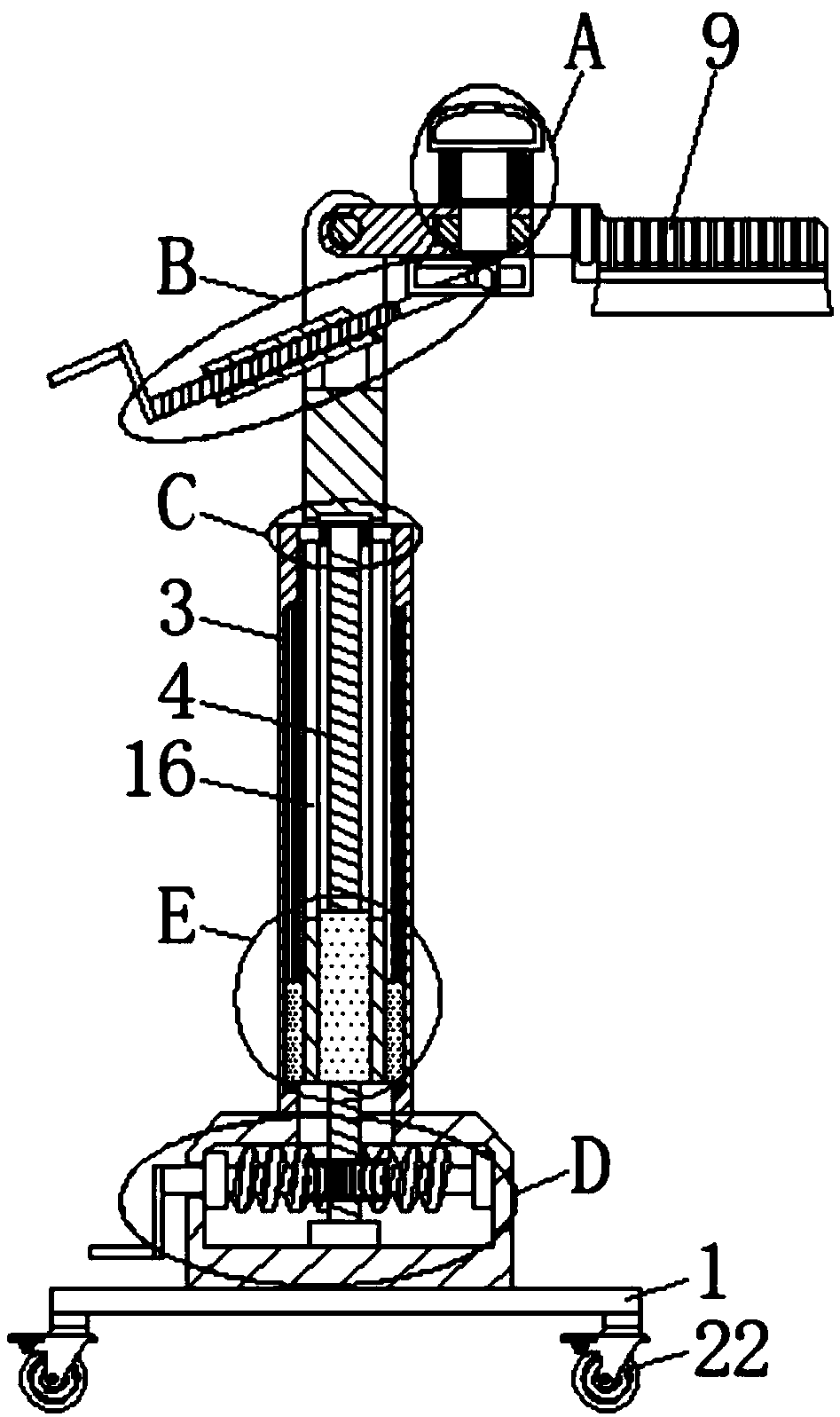

Height-adjustable LED light post

A technology for LED lights and height adjustment, which is applied to parts of lighting devices, semiconductor devices of light-emitting elements, outdoor lighting, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

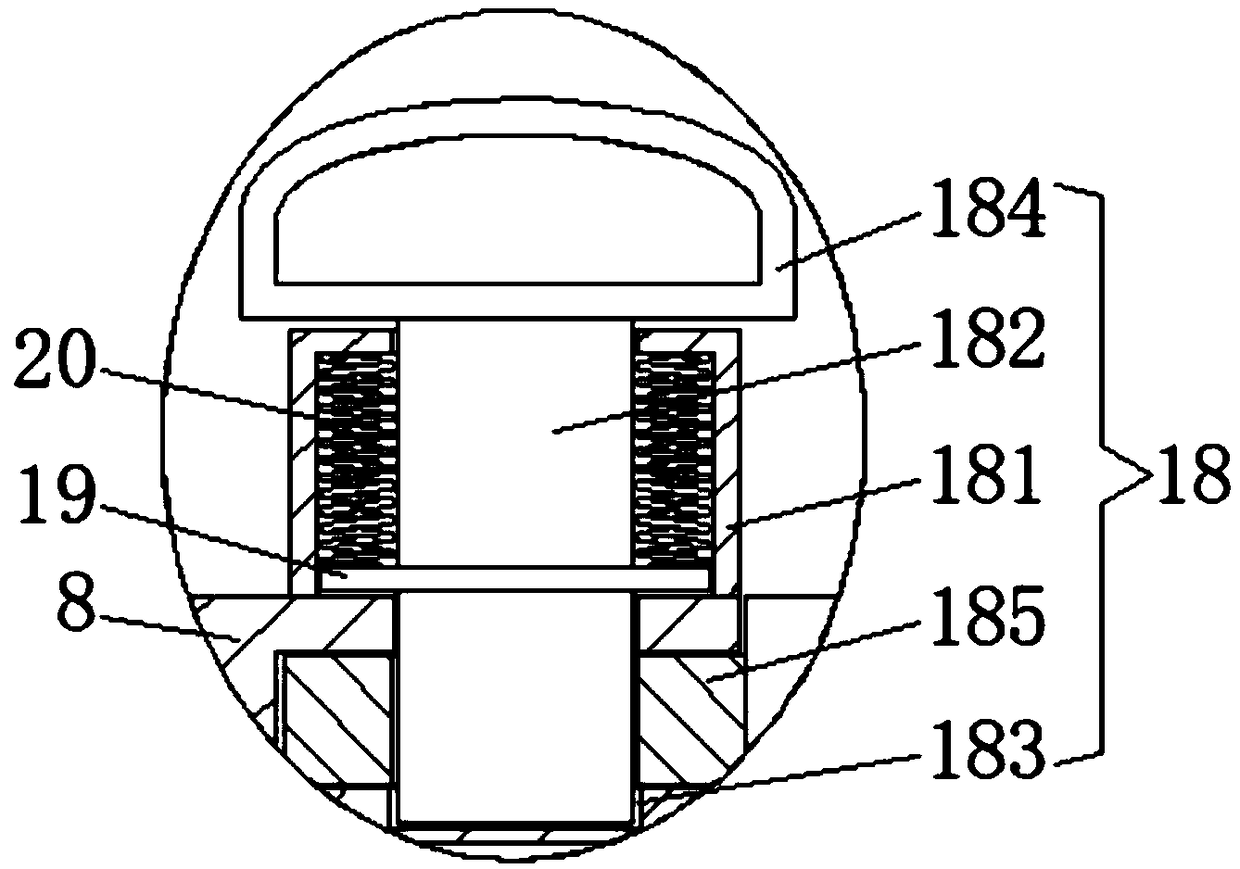

[0036] Embodiment 2: The difference from Embodiment 1 is that the transmission mechanism 10 includes a worm wheel 101, a worm screw 102 and an L-shaped handle 103, and the worm screw 102 is movably connected to the right side of the inner wall of the transmission box 2 through a bearing, and the worm screw 102 is located behind the screw rod 1 4 side, the worm wheel 101 is fixedly connected to the surface of the screw 14, the worm 102 meshes with the worm wheel 101, the L-shaped handle 103 is arranged on the left side of the transmission box 2, and the right end of the worm 102 penetrates to the right side of the transmission box 2 and is fixedly connected to the The top of the right side of the L-shaped handle 103, by setting the worm gear 101 and the worm screw 102, can drive the screw rod 14 to rotate, reduce the rotation speed of the screw rod 14, and improve the transmission strength of the L-shaped handle 103 to the screw rod 4, The screw rod-4 is more stable when rotatin...

Embodiment 3

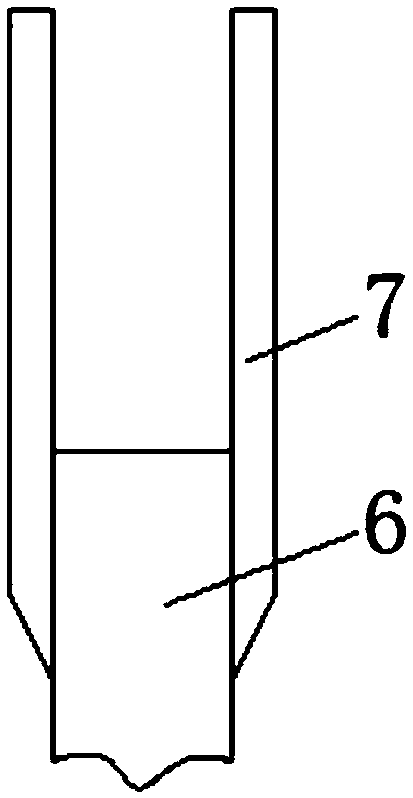

[0037] Embodiment 3: The difference from Embodiment 1 is that the bottoms on both sides of the transmission cylinder 6 are fixedly connected with sliders 11, and both sides of the inner wall of the support cylinder 3 are provided with chute 12, and the sliders 11 are slidably connected to the sides of the chute 12. Inside, the inside of the chute 12 is vertically fixedly connected with a slide bar 13, and the slide block 11 is sleeved on the surface of the slide bar 13. By setting the slide block 11 and the chute 12, the screw sleeve 1 can be limited to prevent the screw sleeve from The sleeve-5 rotates when moving up and down, which improves the stability of the screw sleeve-5 when moving.

Embodiment 4

[0038] Embodiment 4: The difference from Embodiment 1 is that the top of the surface of the screw rod 4 is movably connected with the limit sleeve 14 through bearings, and both sides of the limit sleeve 14 are fixedly connected with the limit plate 15, and both sides of the transmission cylinder 6 are equipped with Opening 16, the limit plate 15 passes through the opening 16 away from the side of the limit sleeve 14 and is fixedly connected with the inner wall of the support tube 3. By setting the limit sleeve 14 and the limit plate 15, the top of the screw rod-4 can be fixed. The degree of support avoids the phenomenon that the screw rod-4 shakes when it rotates, and improves the stability of the screw rod-4 when it rotates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com