Ship-land multi-layer target for high-speed penetration evaluation effectiveness test

An effectiveness test and target technology, applied in ammunition tests, targets, weapon accessories, etc., can solve problems that do not meet the boundary conditions of the actual ship frame structure and deck, and cannot effectively reflect the penetration capability of anti-ship missiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

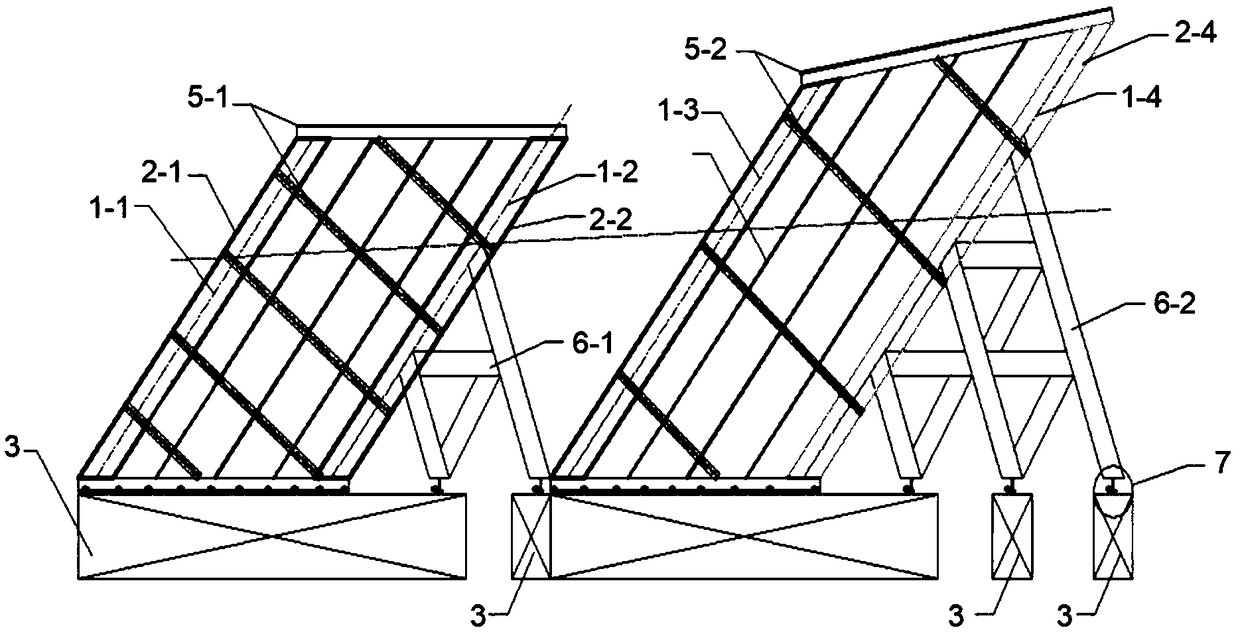

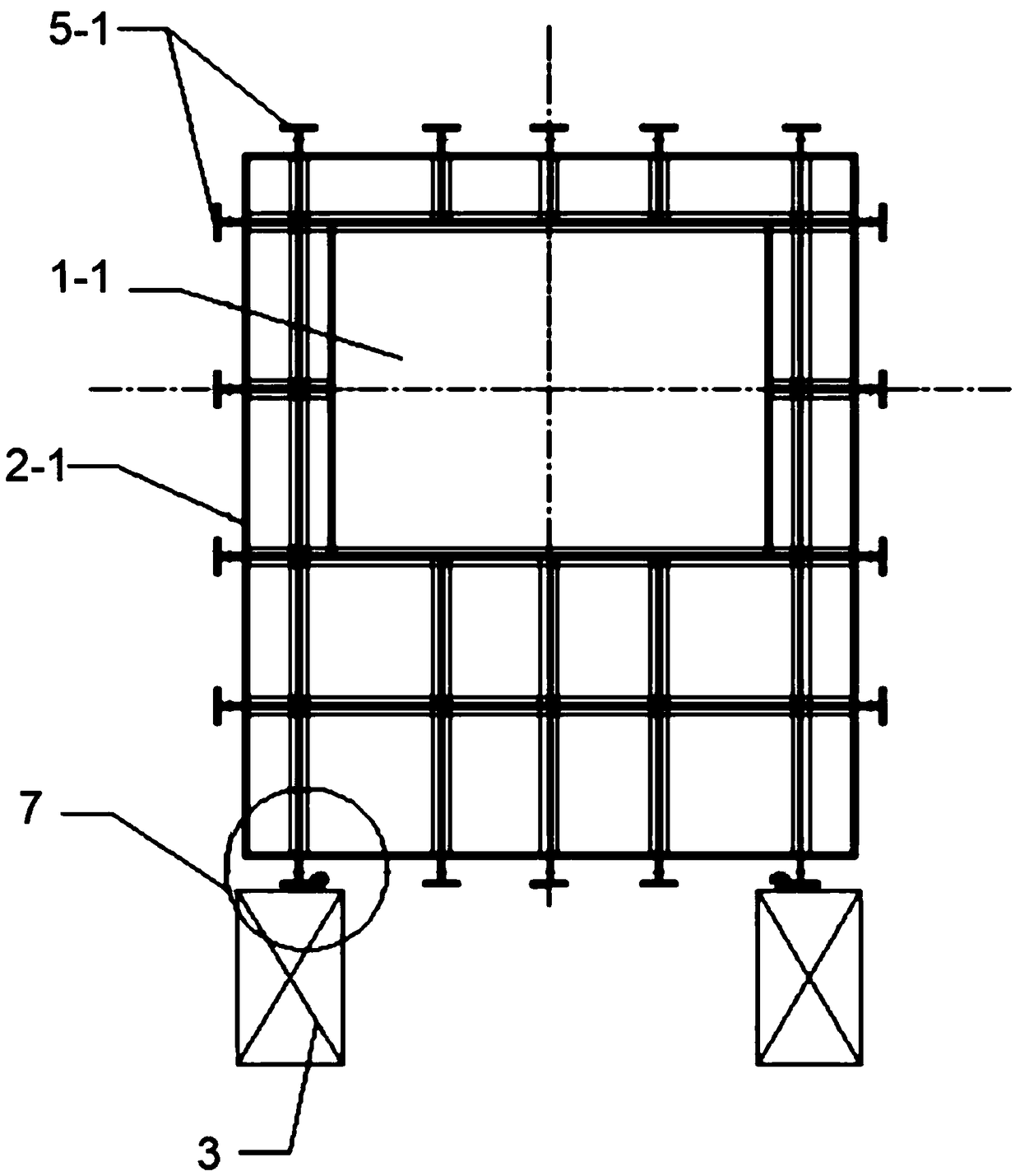

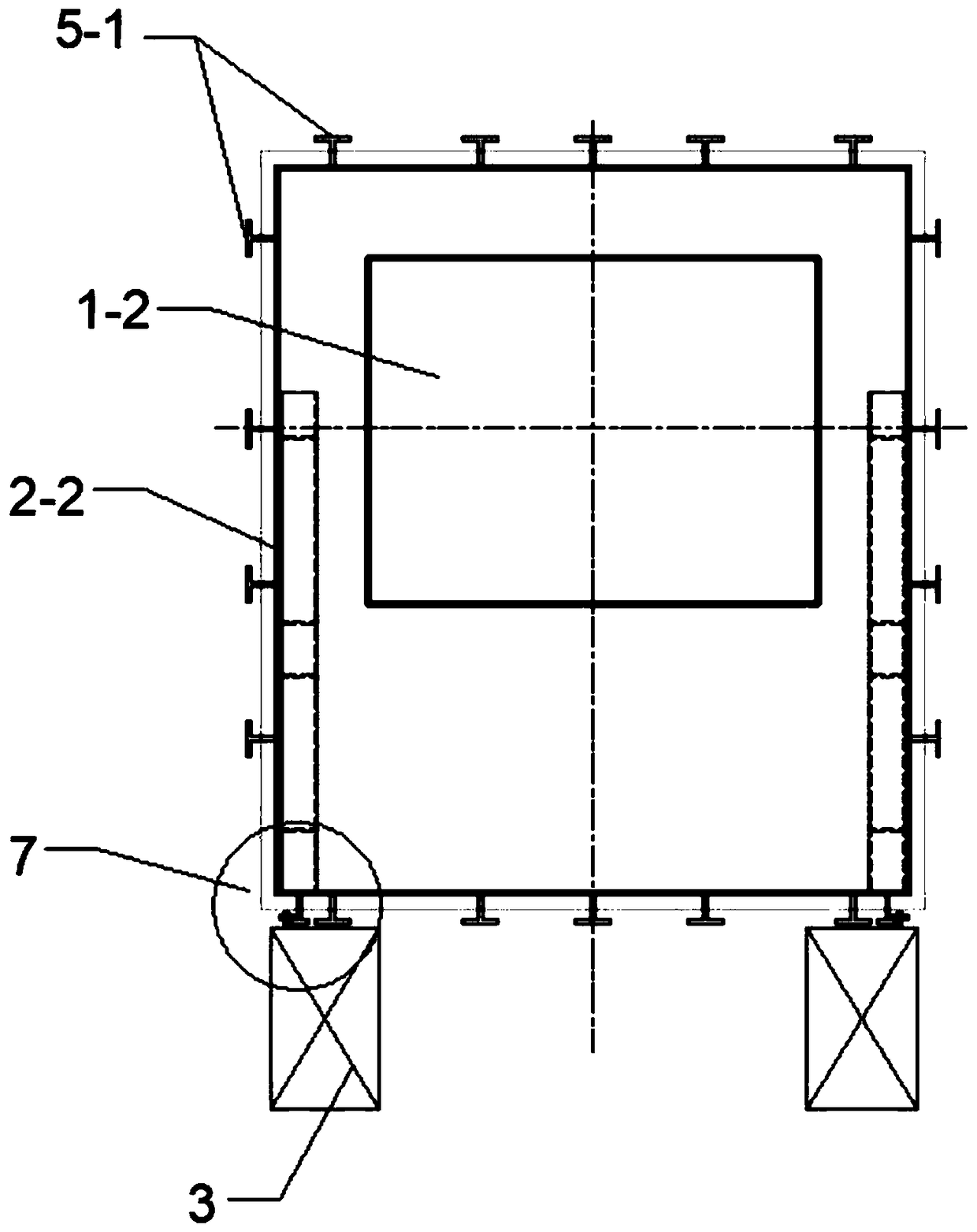

[0029] Aiming at the target ship of the penetration test, the present invention proposes a ship land multi-layer target for the high-speed penetration evaluation effectiveness test. The target system is used to simulate the high-speed penetration test research of large and medium-sized destroyers and frigates. The target system includes two parts, namely the front target system and the rear target system. Each part constitutes an independent whole. The front target system includes the target surface 1-1 , target surface 1-2, plate frame fixing frame 2-1, plate frame fixing frame 2-2, module table top 3, bolt holes 4, connection structure 5-1, frame support structure 6-1, target system fixing structure 7, Rib 8-1 on the fixed frame, rib 8-2 on the fixed frame, rib 9-1 on the target surface, rib 9-2 on the target surface; the rear target system includes target surface 1-3, target surface 1- 4. Plate frame fixing frame 2-3, plate frame fixing frame 2-4, module table top 3, bolt h...

Embodiment 2

[0048]A ship land multi-layer target for high-speed penetration evaluation performance test, the target system includes two parts, namely the front target system and the rear target system, the front target system includes target surface 1-1, target surface 1 -2, panel frame fixing frame 2-1, panel frame fixing frame 2-2, module table top 3, bolt holes 4, connection structure 5-1, frame support structure 6-1, target system fixing structure 7, reinforcement on the fixing frame Rib 8-1, rib 8-2 on the fixed frame, rib 9-1 on the target surface, rib 9-2 on the target surface; the rear target system includes target surface 1-3, target surface 1-4, and plate frame Fixed frame 2-3, plate frame fixed frame 2-4, module table top 3, bolt holes 4, connection structure 5-2, frame support structure 6-2, target system fixed structure 7, reinforcement ribs on the fixed frame 8-3, Rib 8-4 on the fixed frame, rib 9-3 on the target surface, rib 9-4 on the target surface; target surface 1-1, ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com