Front cassette type jack and tool anchorage equipment for prestress tension

A jack and tool anchor technology, which is applied in the field of bridge prestress tension test, can solve the problem of inability to detect the retraction amount of tool clips, and achieve the effect of improving tensioning efficiency and tensioning control accuracy and saving steel strands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

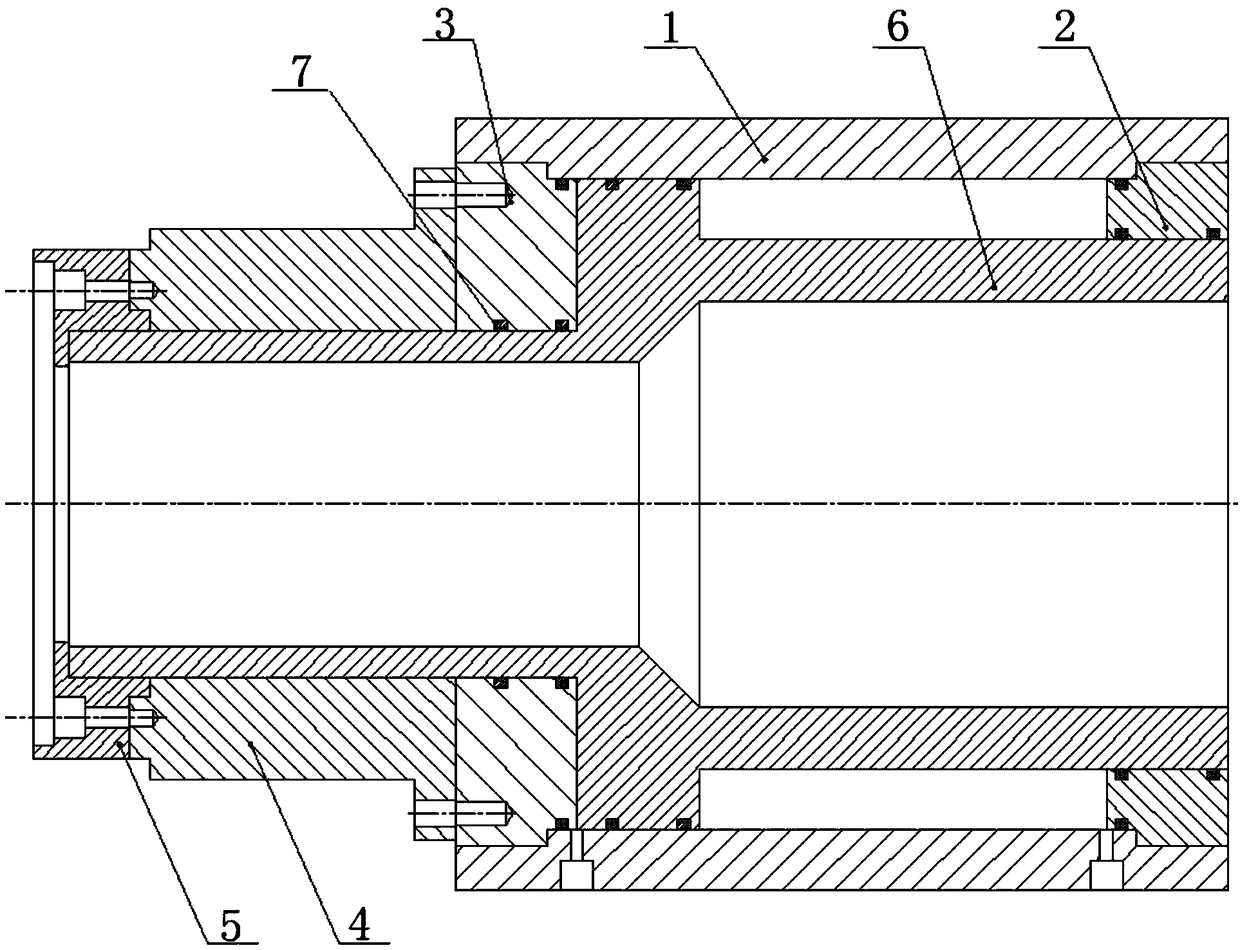

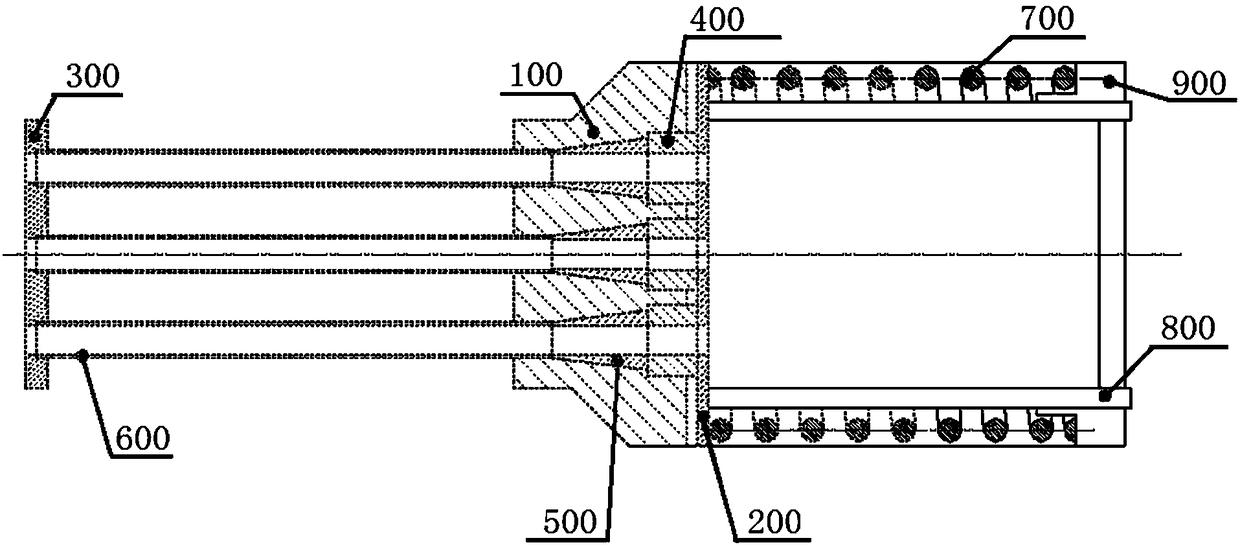

[0052] Such as figure 2 As shown, the front clamp tool anchor device includes a tool anchor plate 100, a front push plate 200, a push back plate 300, a push sleeve 400, a tool clip 500, a push back rod 600, a push spring 700 and a retraction probe rod 800; the rear end of the tool anchor plate 100 is provided with the front push plate 200, and the front end of the tool anchor plate 100 is provided with the push back plate 300; the tool anchor plate 100 is provided with a through hole; One end of the front push sleeve 400 is installed at the rear end in the through hole, and the other end of the front push sleeve 400 is located outside the through hole and connected with the front push plate 200; the tool clip 500 is installed In the middle of the through hole, it is connected to one end of the forward push sleeve 400 located in the through hole; one end of the push back rod 600 passes through the push back plate 300, and the push back rod 600 passes through the push back plat...

Embodiment 2

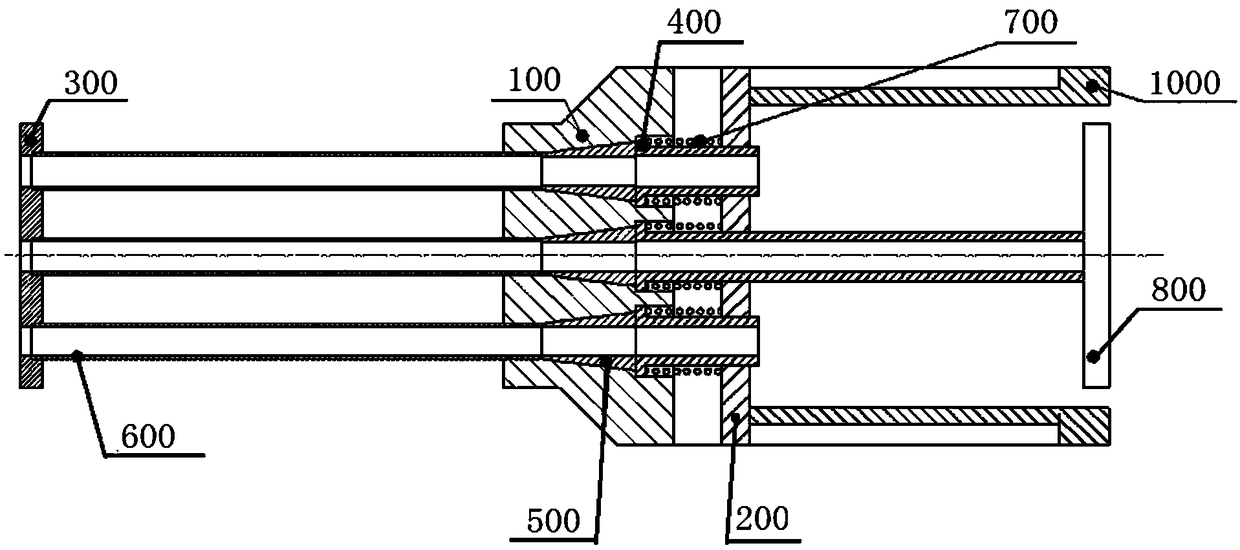

[0056] Such as image 3 As shown, the front clamp tool anchor device includes a tool anchor plate 100, a front push plate 200, a push back plate 300, a push sleeve 400, a tool clip 500, a push back rod 600, a push spring 700 and a retraction probe rod 800; the rear end of the tool anchor plate 100 is provided with the front push plate 200, and the front end of the tool anchor plate 100 is provided with the push back plate 300; the tool anchor plate 100 is provided with a through hole; One end of the front push sleeve 400 is installed at the rear end in the through hole, and the other end of the front push sleeve 400 is located outside the through hole and connected with the front push plate 200; the tool clip 500 is installed In the middle of the through hole, it is connected to one end of the forward push sleeve 400 located in the through hole; one end of the push back rod 600 passes through the push back plate 300, and the push back rod 600 passes through the push back plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com