A kind of production method of cold-rolled stainless steel embossed plate

A technology of cold-rolled stainless steel and a production method, applied in the field of stainless steel embossing, can solve the problems that mechanical properties cannot meet the needs of stamping with large deformation, and achieve the effects of good appearance, simple production process and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

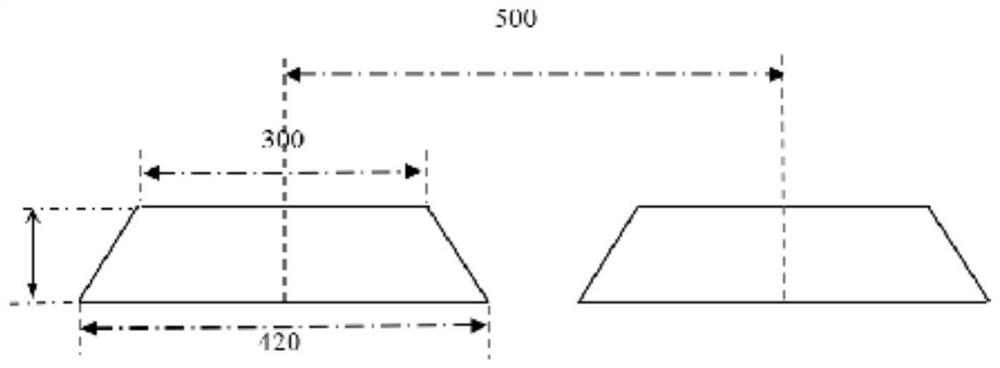

[0020] Use SUS304 stainless steel pickling coil with a thickness of 3mm and a width of 1200mm, rough rolling to 2.0mm, rough grinding once, finish rolling three times to 0.6mm, enter the first annealing process, annealing temperature 1080 ° C, and then use embossing work Roll rolling, embossing rolling force 2000KN, enter the second annealing process, annealing temperature 1030 ℃, coiling and storage after tension leveling.

Embodiment 2

[0022] Use SUS304 stainless steel pickling coils with a thickness of 3.5mm and a width of 1100mm, rough rolling to 2.2mm, rough grinding once to remove microscopic defects on the strip surface, finishing rolling three times to 0.7mm, enter the annealing process, annealing temperature 1100 ° C, and then use Embossing work roll rolling, embossing rolling force 1800KN, enter the final annealing process, annealing temperature 1050 ℃, coiling and storage after tension leveling.

Embodiment 3

[0024] Use SUS304 stainless steel pickling coils with a thickness of 4.0mm and a width of 1000mm, rough rolling to 2.5mm, rough grinding once, finish rolling three times to 0.8mm, enter the annealing process, annealing temperature 1120°C, and then roll with embossing work rolls , embossing and rolling force 1600KN, enter the final annealing process, annealing temperature 1070 ℃, coiling and storage after tension leveling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com