Small and medium-sized ring horse frame reaming rotation control device and its application method

A technology of small and medium-sized ring parts, applied in the field of forging, can solve the problems of low degree of automation, uneven wall thickness, out-of-round ring parts, etc., and achieve the effect of stable working conditions, stable forming process, and controllable rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

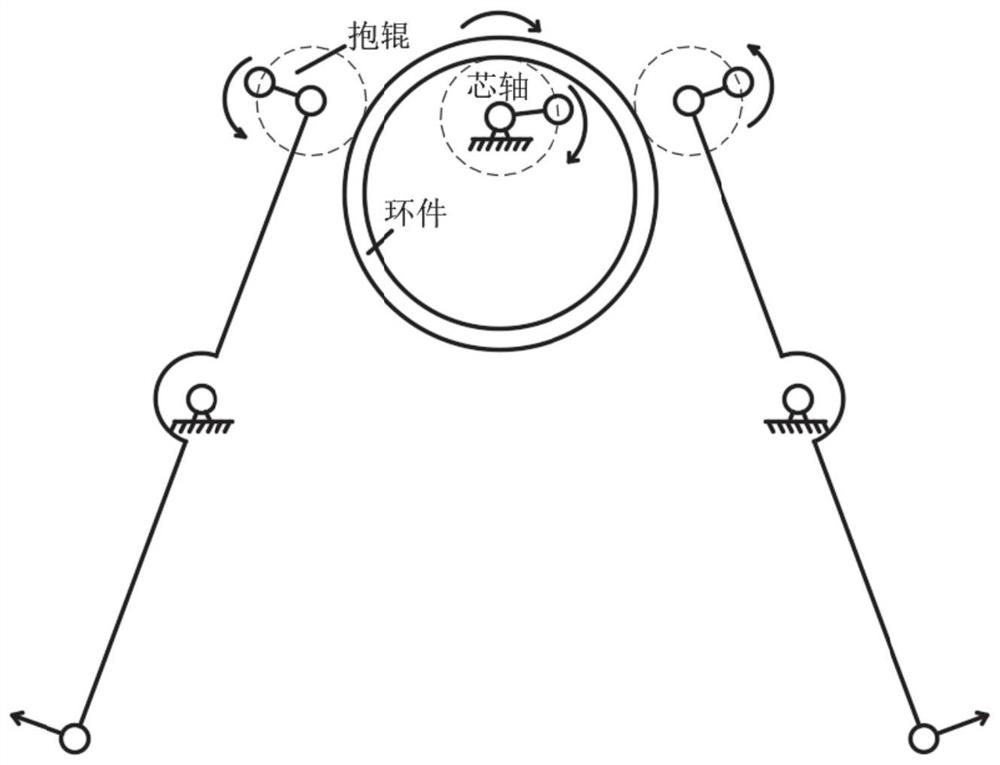

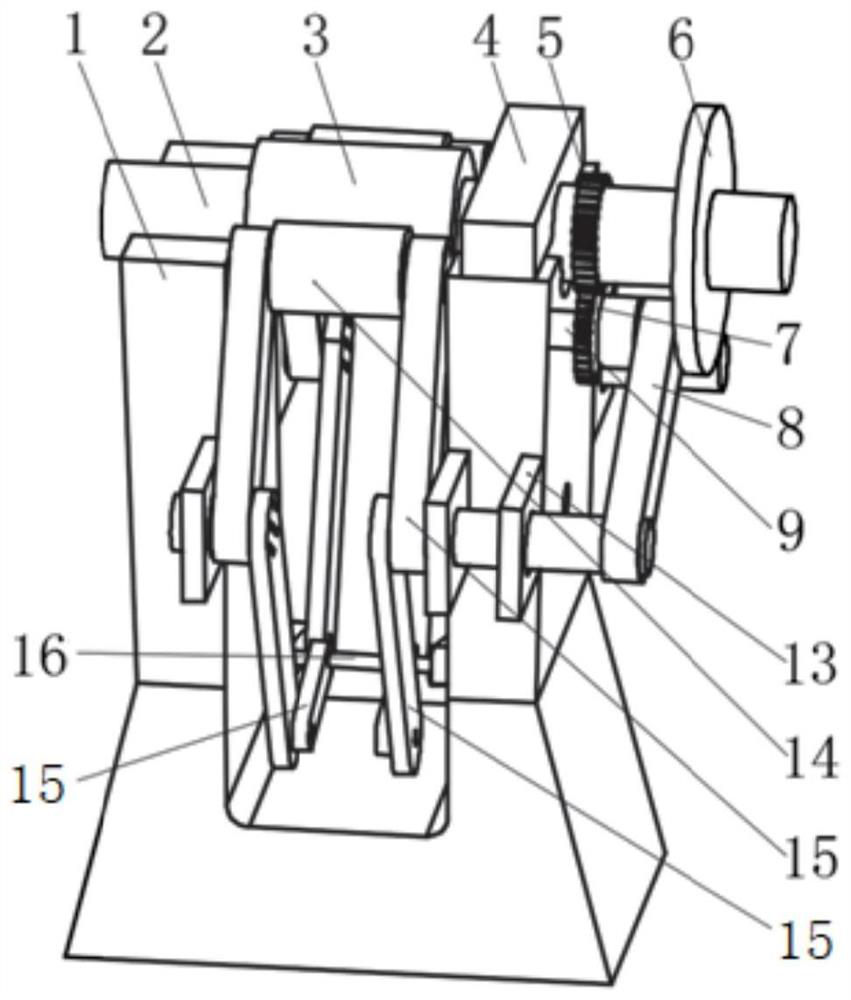

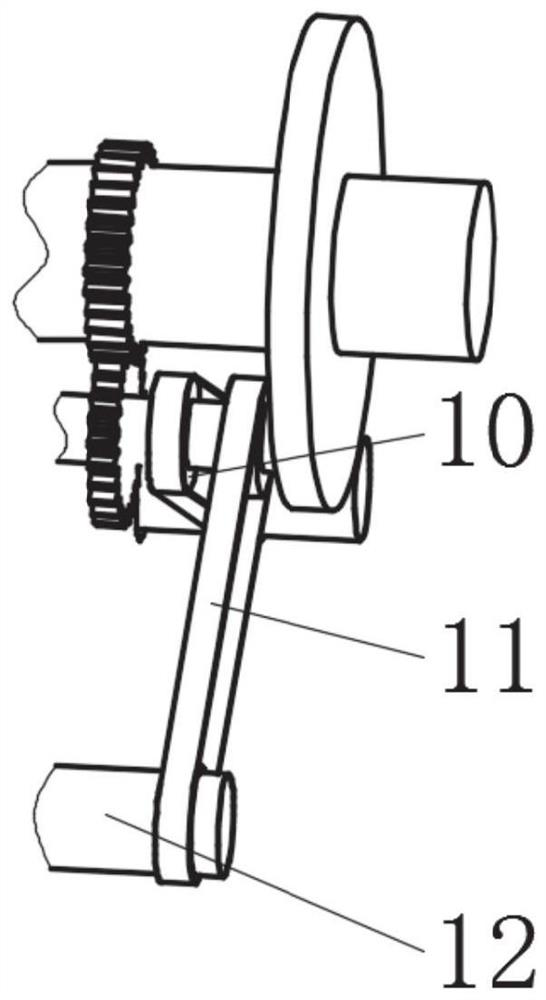

[0040] Such as Figure 1 to Figure 6 As shown, in Embodiment 1 and Embodiment 2, the small and medium-sized ring horse frame reaming rotation control device includes a horse frame 1, a rotatable and detachable ring mounted on the horse frame 1 and used to pass through the ring 3 The mandrel 2, the mandrel 2 driving member for driving the mandrel 2 to rotate, two groups of symmetrical holding roller 14 assemblies arranged on both sides of the mandrel 2, the holding roller 14 assembly includes a lever 15 that can swing toward the mandrel 2, The rotatable holding roller 14 that is located at one end of the lever 15 and is used to press down the ring 3, the holding roller 14 driving member that is used to drive the holding roller 14 to rotate, is connected with the other end of the lever 15 and is used to drive the holding roller 14 Swinging le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com