Piston ring manufacturing equipment

A technology for manufacturing equipment and piston rings, applied in the field of piston ring manufacturing equipment, can solve the problems of piston ring deformation, reduce practicability, affect the use effect of piston rings, etc., and achieve the effect of fine piston rings and improved shape stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

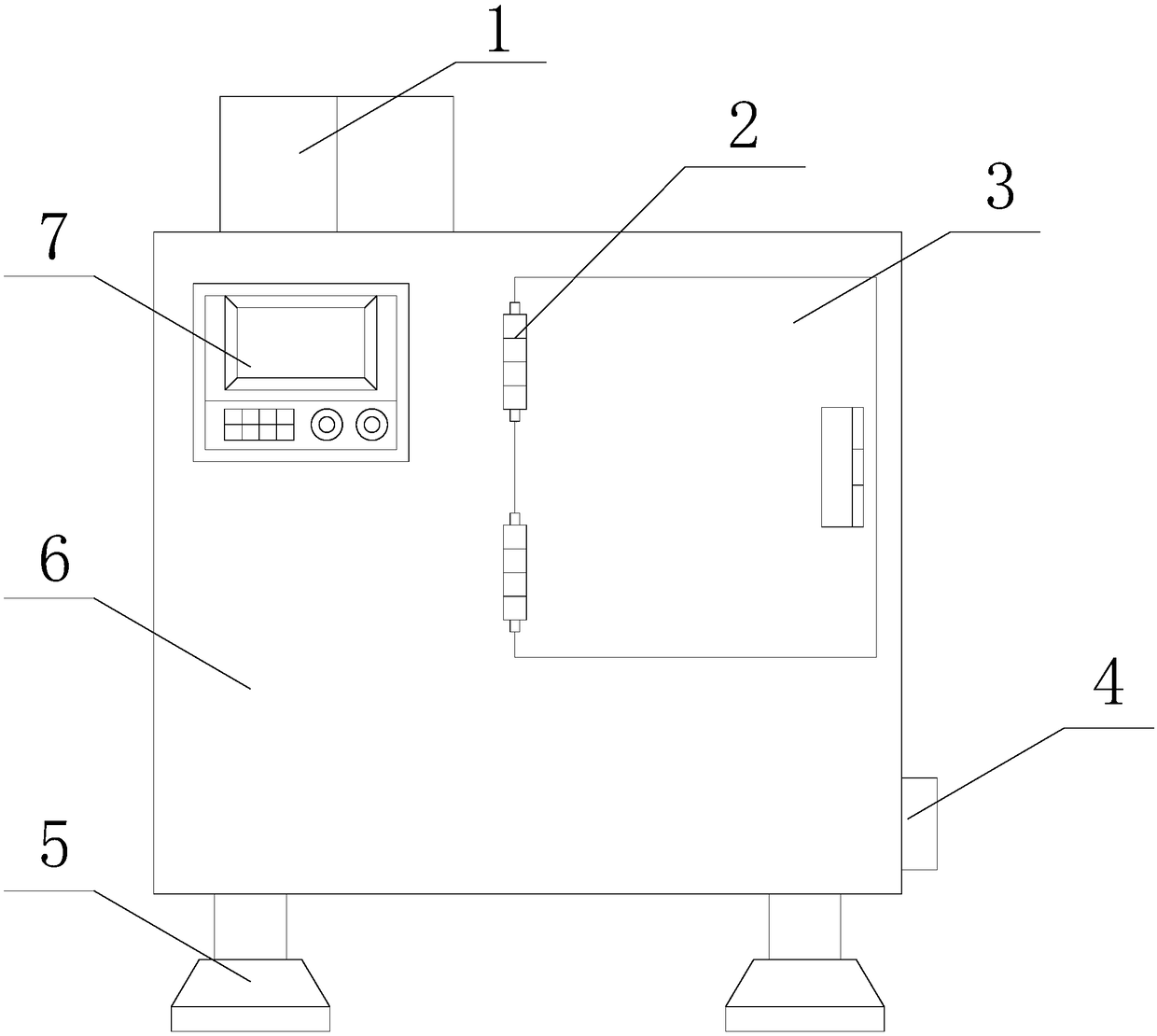

[0025] see Figure 1-Figure 6 , the present invention provides piston ring manufacturing equipment, the structure of which includes a raw material box 1, a hinge 2, a box door 3, a ring outlet 4, a support foot 5, a manufacturing host 6, and an operation panel 7, and the raw material box 1 is fixedly installed on the manufacturing host 6 at the upper left end, the box door 3 is connected to the front surface of the manufacturing host 6 through a hinge 2, the left end of the ring outlet 4 is installed on the lower right end of the manufacturing host 6 by embedding, and the supporting feet 5 are provided with four and It is fixedly installed at the four corners of the manufacturing mainframe 6, and the operation panel 7 is embedded in the front surface of the left end of the manufacturing mainframe 6 and electrically connected by wires.

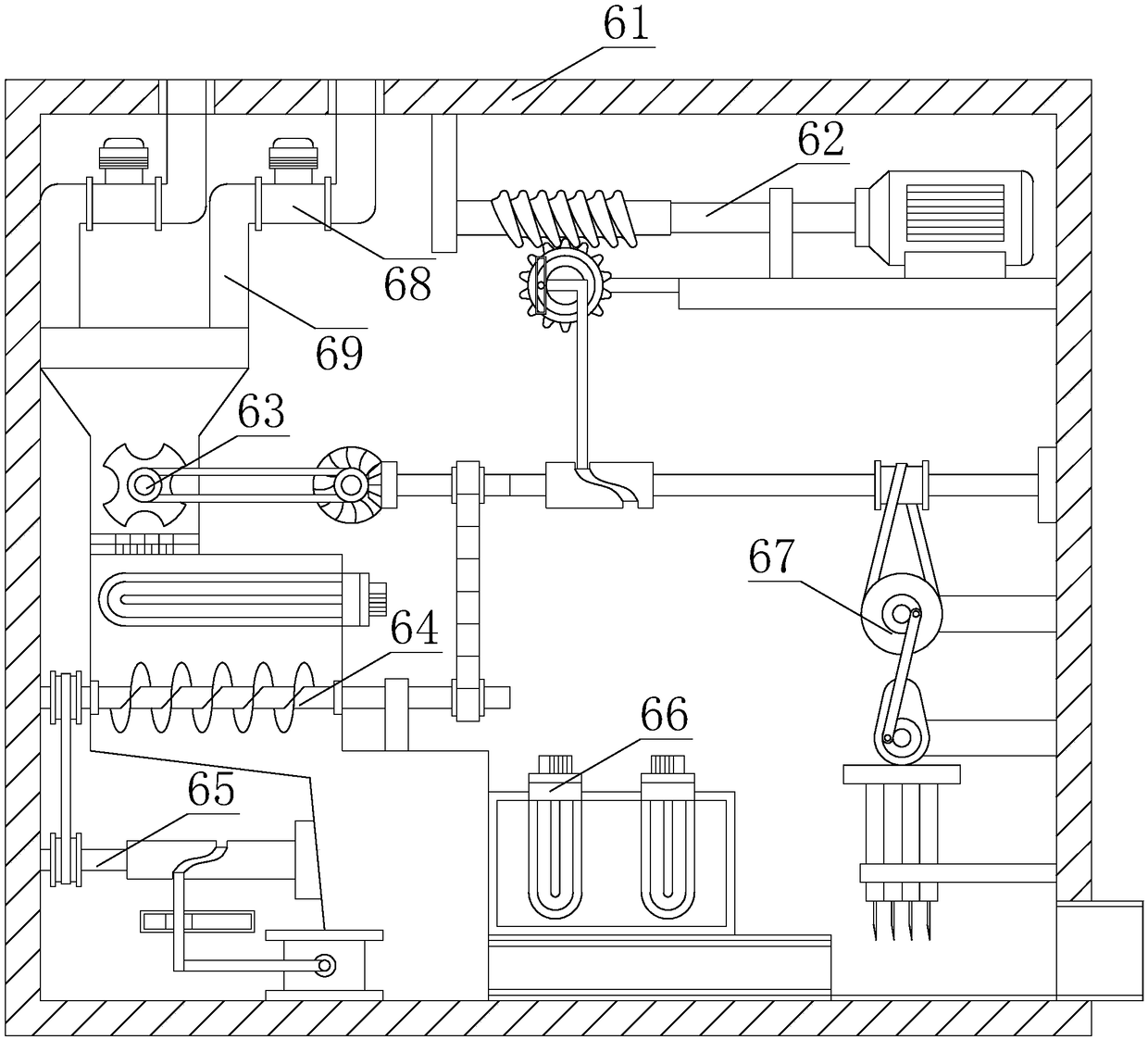

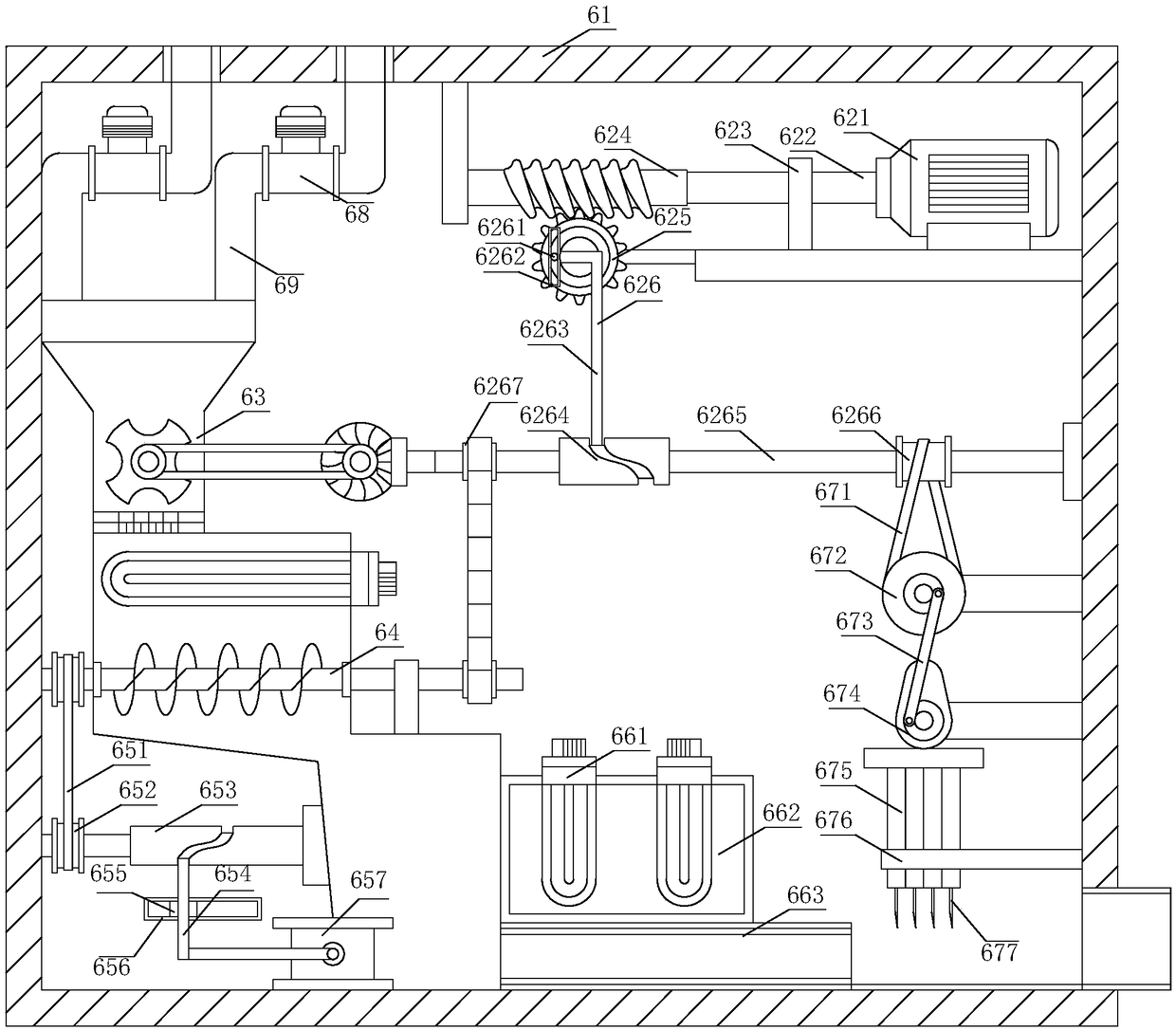

[0026]The manufacturing host 6 includes a shell 61, a power mechanism 62, a screening mechanism 63, a stirring mechanism 64, a boosting mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com