Automatic film tearing equipment

A kind of equipment and automatic technology, applied in the direction of conveyor objects, transportation and packaging, can solve problems such as high cost, product quality impact, breakdown damage, etc., to achieve the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0041] CCD, English full name: Charge coupled Device, Chinese full name: charge coupled device, can be called a CCD image sensor. CCD is a semiconductor device that converts optical images into digital signals.

[0042] Specifically, the product mentioned in this proposal can be a camera module, and of course it can also be other products that require automatic film tearing.

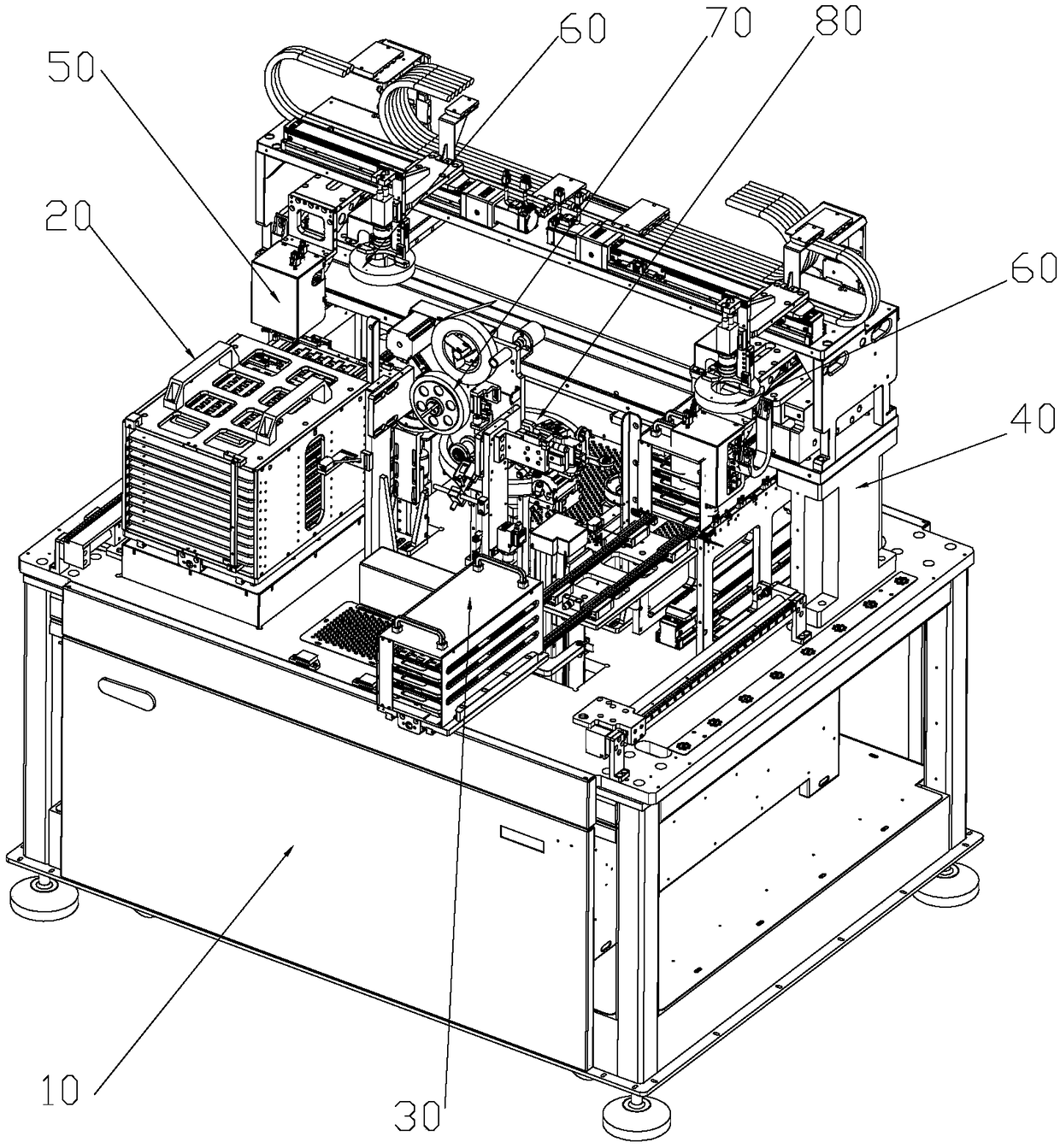

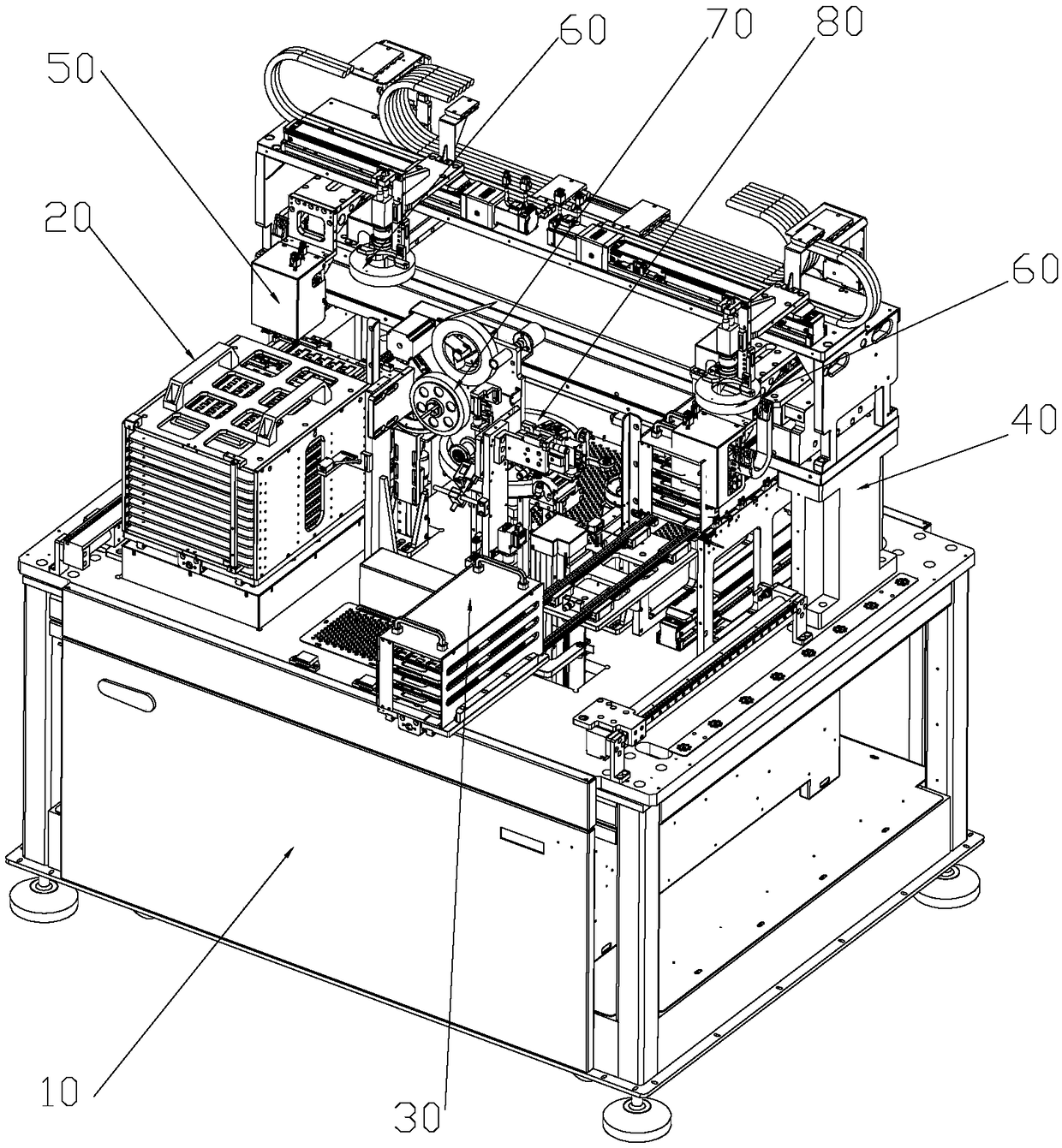

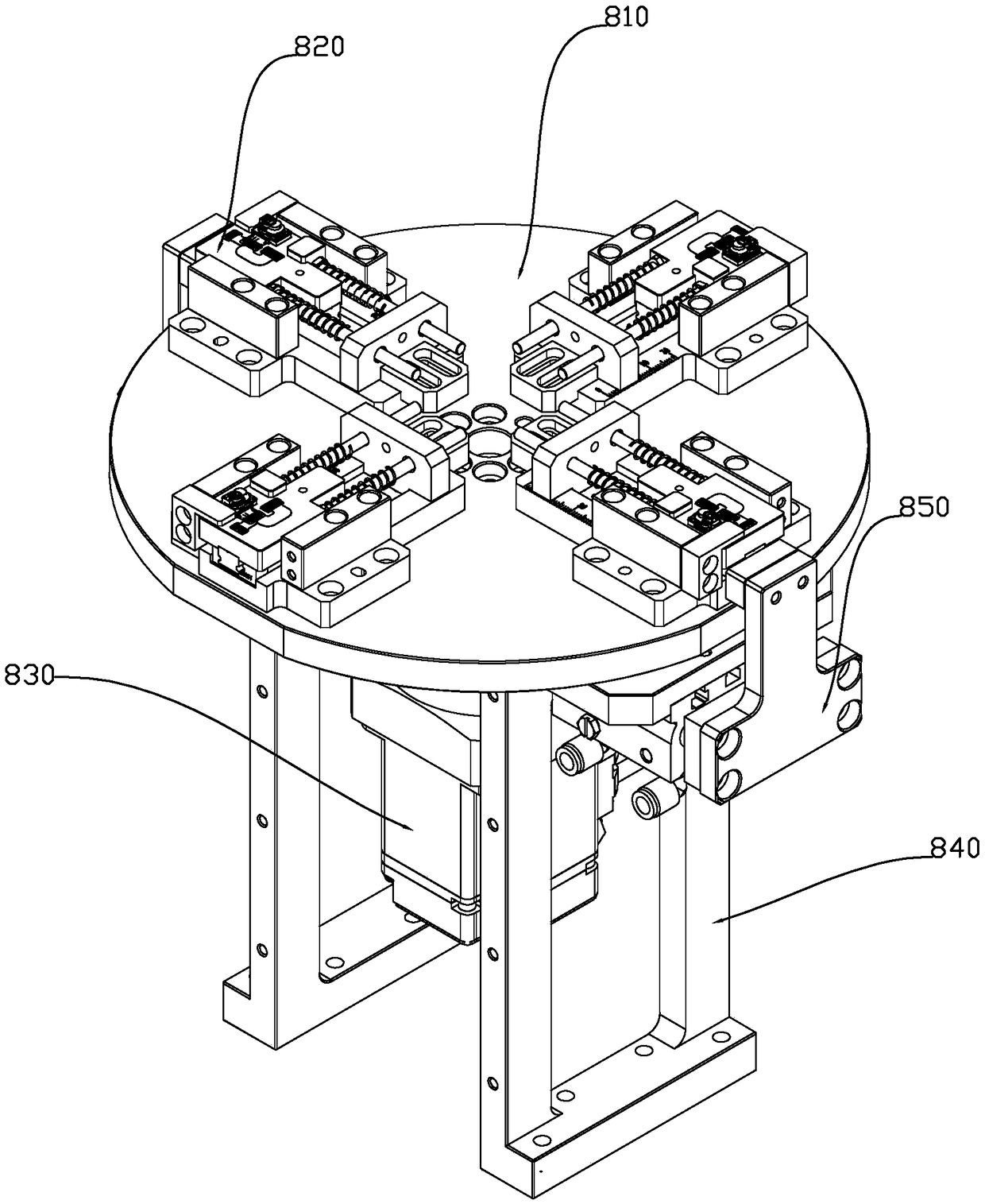

[0043] refer to Figure 1-11 , a specific embodiment of the present invention proposes an automatic film tearing device, comprising:

[0044] The workbench 10 is used to set the feeding mechanism 20, the receiving mechanism 30, the gantry frame 40, the film tearing mechanism 70 and the turntable mechanism 80, as the support of the whole equipment, to ensure the stable progress of the whole production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com