Built-in touch screen and manufacturing method thereof

A technology of an in-cell touch screen and a manufacturing method, which is applied in the directions of light guide, optics, instruments, etc., can solve the problems of difficult in-cell touch screen full lamination process, scrapped display screen, low assembly yield, etc. Reduced, does not affect the light output effect, the effect of thin and light touch screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The purpose of the present invention can be achieved through the following technical solutions:

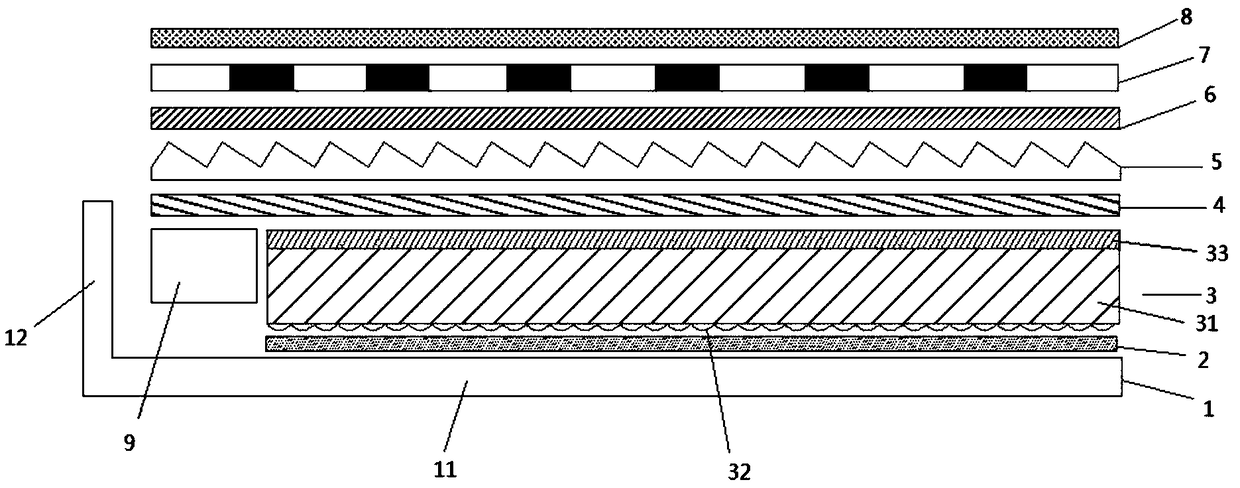

[0039] An embedded touch screen, see figure 1 , including module frame 1, reflective sheet 2, touch light guide plate 3, lower diffuser plate 4, prism sheet 5, upper diffuser plate 6, LCD liquid crystal panel 7, cover glass 8, LED light source 9;

[0040] The module frame 1 includes a back plate 11 and a frame 12, and an LED light source 9 is arranged on the inner wall of the frame 12; the upper surface of the back plate 11 is sequentially provided with a reflective sheet 2, a touch light guide plate 3, a lower diffusion plate 4, and a prism sheet 5. Upper diffusion plate 6, LCD liquid crystal panel 7, cover glass 8;

[0041]The touch light guide plate 3 includes a light guide structural plate 31, dots 32, and an ITO transparent touch film 33. The lower surface of the light guide structural plate 31 is provided with dots 32, and the upper surface of the light guide structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com