Method and system for determining battery temperature

A battery temperature and determination method technology, applied to secondary batteries, circuits, electrical components, etc., can solve problems such as inaccurate determination of battery temperature, achieve accurate display of battery temperature, reasonable handling and use, and avoid potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

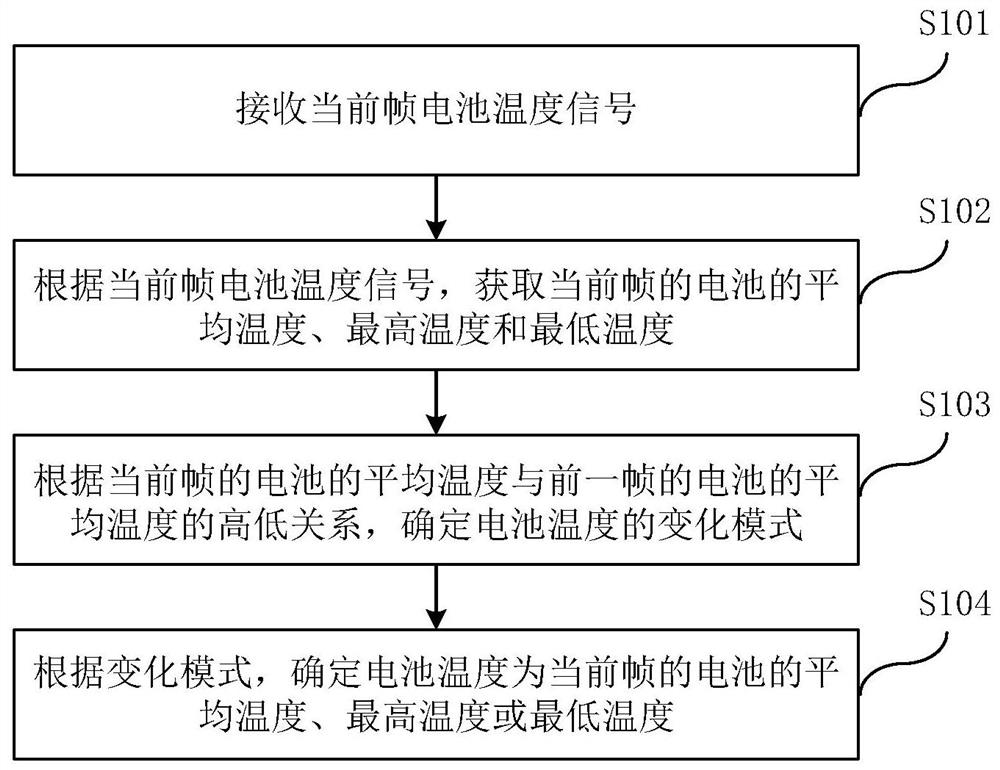

[0036] The first embodiment of the present invention discloses a method for determining battery temperature. The battery temperature determination method is used in electric vehicles. The battery is generally a power storage battery of an electric vehicle. Such as figure 1 As shown, the battery temperature determination method includes the following process:

[0037] Step S101: Receive the current frame battery temperature signal.

[0038] The battery of an electric vehicle has a complex structure, including multiple sensors for measuring temperature. Each sensor can signal the temperature of the battery. In this embodiment, multiple battery temperature signals are aggregated into three battery temperature signals, which respectively contain information about the average temperature, the highest temperature, and the lowest temperature. The battery temperature signal can be received via the CAN line. In addition, the battery temperature signal is generated and sent accordin...

no. 2 example

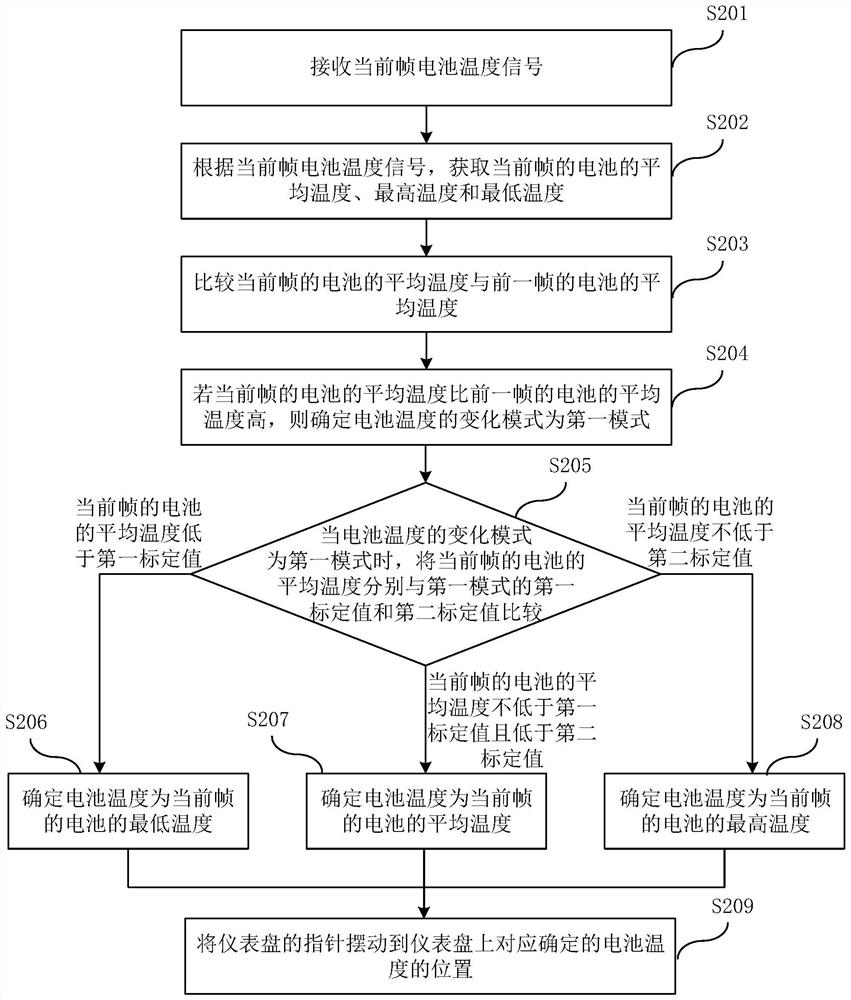

[0051] The second embodiment of the present invention discloses a method for determining battery temperature. The battery temperature determination method is used in electric vehicles. The battery is generally a power storage battery of an electric vehicle. Such as figure 2 As shown, the battery temperature determination method includes the following processes:

[0052] Step S201: Receive the current frame battery temperature signal.

[0053] Step S202: Obtain the average temperature, maximum temperature and minimum temperature of the battery in the current frame according to the battery temperature signal in the current frame.

[0054] Steps S201-S202 are the same as steps S101-S102, and will not be repeated here.

[0055] Step S203: comparing the average temperature of the battery in the current frame with the average temperature of the battery in the previous frame.

[0056] Through this step, the high-low relationship between the two is compared in order to determine...

no. 3 example

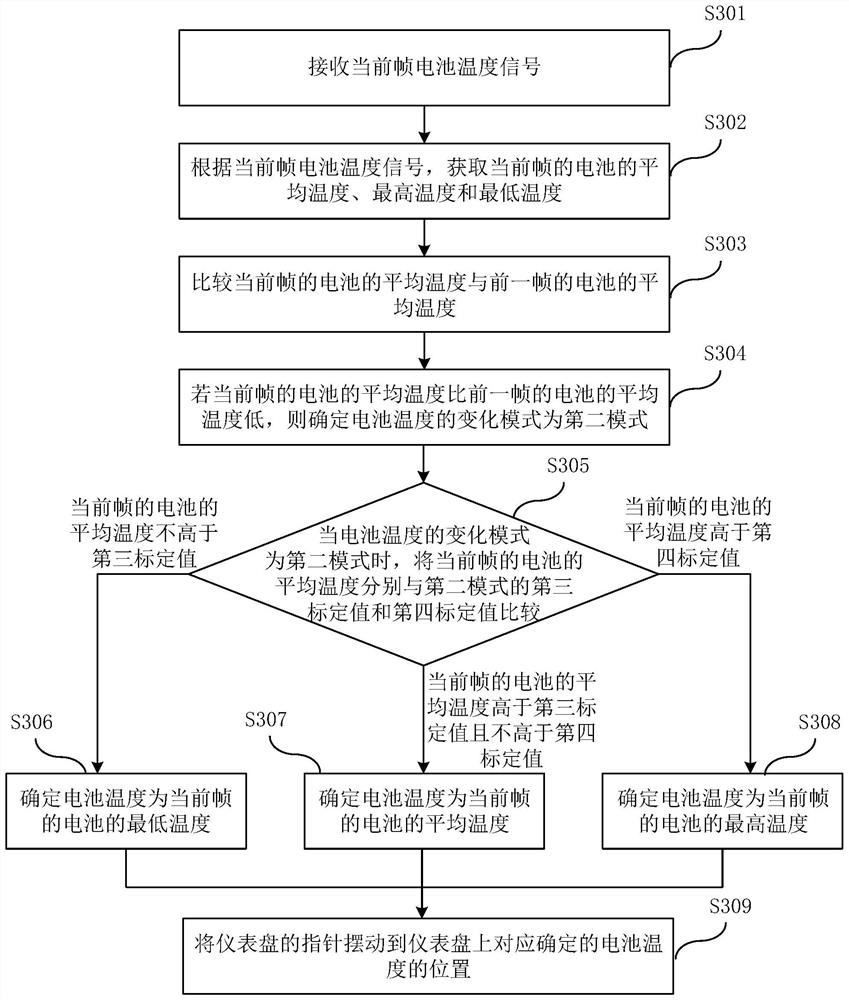

[0074] The third embodiment of the present invention discloses a method for determining battery temperature. The battery temperature determination method is used in electric vehicles. The battery is generally a power storage battery of an electric vehicle. Such as image 3 As shown, the battery temperature determination method includes the following process:

[0075] Step S301: Receive the current frame battery temperature signal.

[0076] Step S302: Obtain the average temperature, maximum temperature and minimum temperature of the battery in the current frame according to the battery temperature signal in the current frame.

[0077] Step S303: comparing the average temperature of the battery in the current frame with the average temperature of the battery in the previous frame.

[0078] Steps S301-S303 are the same as steps S201-S203, and will not be repeated here.

[0079] Step S304: If the average temperature of the battery in the current frame is lower than the averag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com