Motor control mode fault detection method and device

A technology of motor control and fault detection, applied in the direction of motor control, control system, electrical components, etc., can solve the problem of machine explosion and other problems, achieve the effect of improving accuracy and avoiding catastrophic consequences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

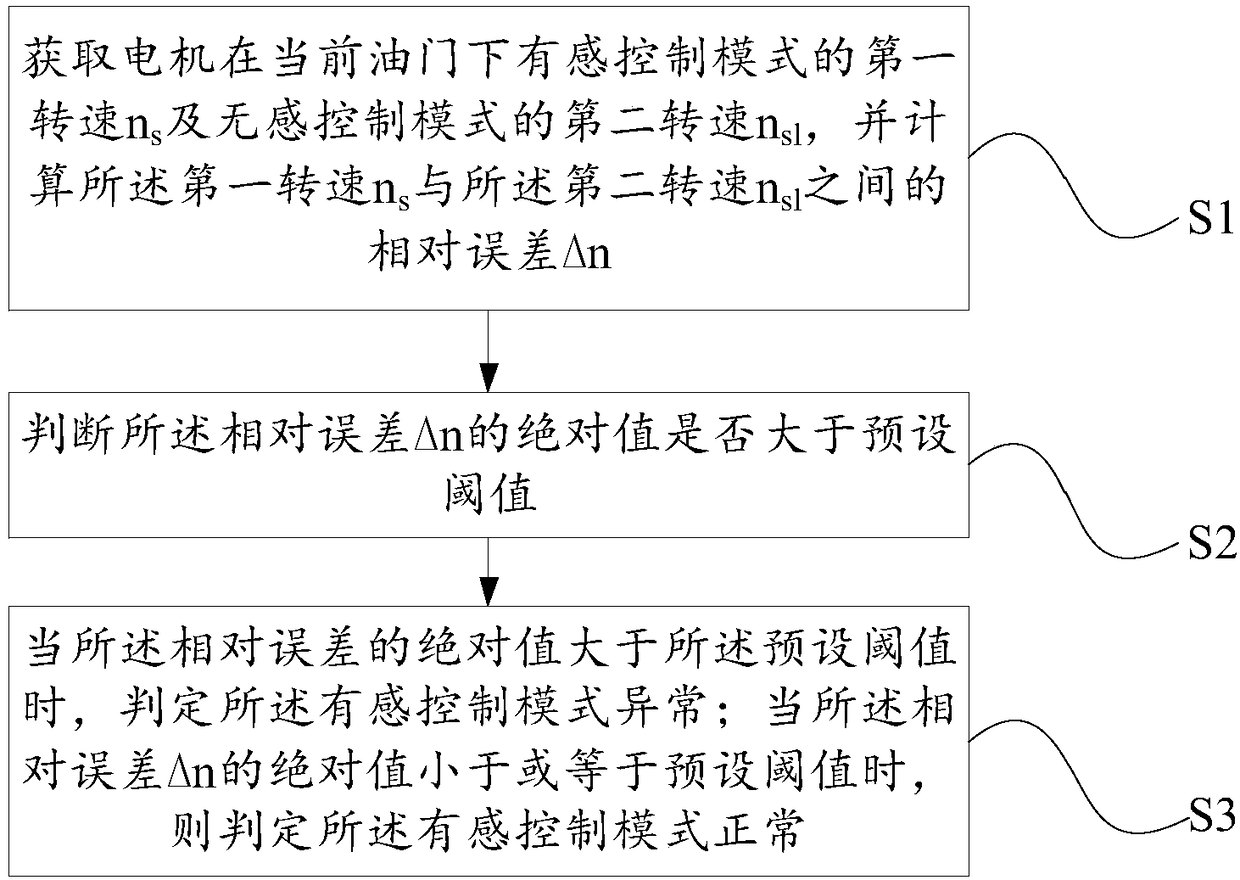

[0045] An embodiment of the present invention provides a motor control mode fault detection method, such as figure 1 As shown, the motor control mode fault detection method mainly includes the following steps:

[0046] Step S1: Obtain the first speed n of the electric motor in the sensory control mode under the current throttle s And the second speed n of the non-inductive control mode sl , and calculate the first rotational speed n s with the second speed n sl The relative error Δn between;

[0047] Step S2: judging whether the absolute value of the relative error Δn is greater than a preset threshold;

[0048]Step S3: When the absolute value of the relative error Δn is greater than the preset threshold, it is determined that the sensory control mode of the motor is abnormal; when the absolute value of the relative error Δn is less than or equal to the preset threshold, it is determined that the sensory control mode of the motor is abnormal The control mode is normal.

...

Embodiment 2

[0093] An embodiment of the present invention provides a motor control mode fault detection device, such as Figure 4 As shown, the motor control mode fault detection device mainly includes: a relative error acquisition unit 1, an error judgment unit 2, an abnormal mode judgment unit 3, and the like.

[0094] Wherein, the above-mentioned relative error acquisition unit 1 is used to acquire the first rotational speed n of the electric motor in the sensed control mode under the current throttle. s And the second speed n of the non-inductive control mode sl , and calculate the first rotational speed n s with the second speed n sl The relative error Δn between them; the error judging unit 2 is used to judge whether the absolute value of the relative error Δn is greater than a preset threshold; the abnormal mode judging unit 3 is used to determine whether the absolute value of the relative error Δn is greater than the preset threshold The sensory control mode of the motor is abn...

Embodiment 3

[0118] Figure 6A and Figure 6B It is a schematic diagram of the hardware structure of the motor control mode fault detection component implementing the motor control mode fault detection method provided by the embodiment of the present invention, as shown in Figure 6A and Figure 6B As shown, the motor control mode fault detection component includes one or more processors 610 and memory 620, Figure 6A and Figure 6B A processor 610 is taken as an example.

[0119] The motor control mode fault detection component implementing the motor control mode fault detection method may further include: an input device 630 and an output device 640 .

[0120] Processor 610, memory 620, input device 630, and output device 640 may be connected by bus or other means, Figure 6A and Figure 6B Take connection via bus as an example.

[0121] The processor 610 may be a central processing unit (Central Processing Unit, CPU). The processor 610 may also be other general-purpose processor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com