Automatic turning and stacking device for straw bales and using method thereof

A technology of automatic turning and turning device, applied in the direction of harvester, etc., can solve the problems of high equipment cost and less research on automatic temporary storage device for straw bales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

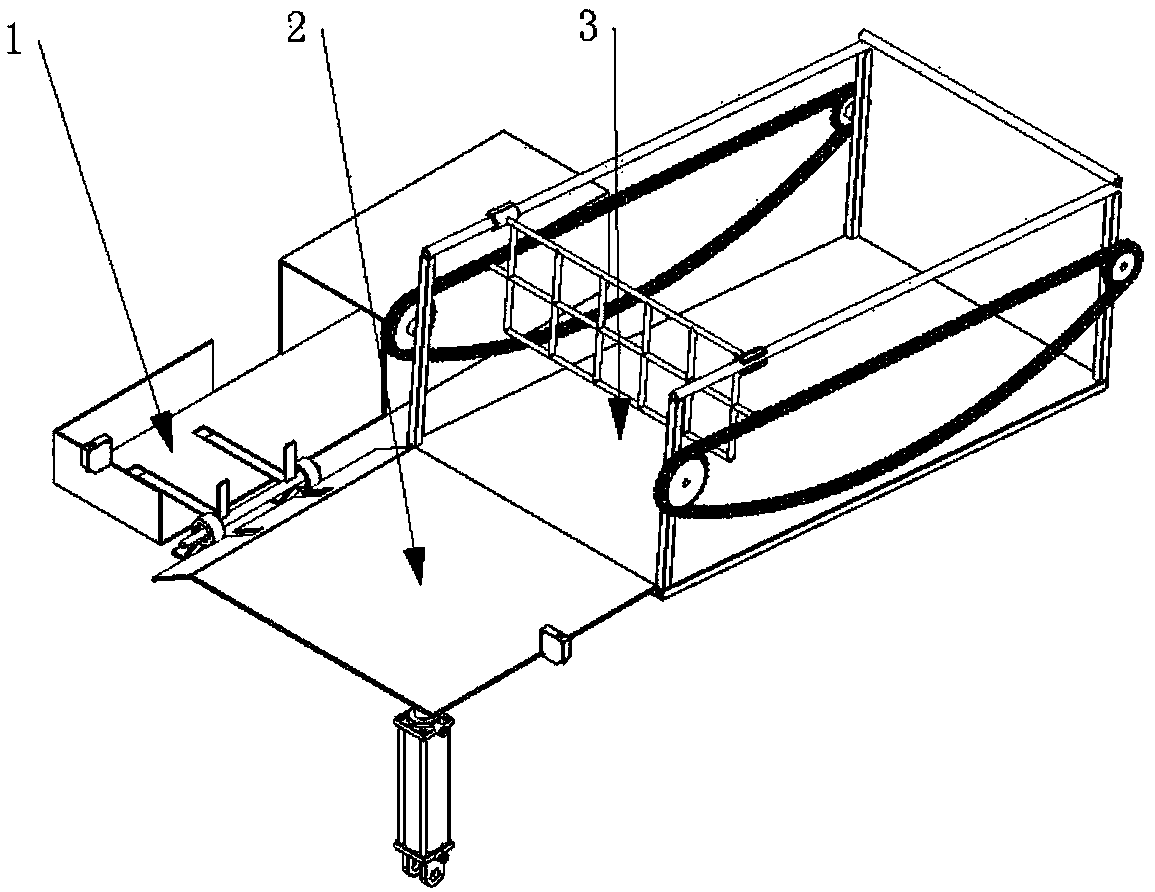

[0048] Such as figure 1 As shown, a straw square bale automatic stacking and stacking device of the present invention includes a bale conveying mechanism 1, a hydraulic standing mechanism 2, and a straw bale temporary storage mechanism 3; the left side of the standing plate 22 of the hydraulic standing mechanism 2 It is connected with the transition plate 146 on the side of the tail of the bale conveying mechanism 1, and the front end of the vertical plate 22 of the hydraulic vertical mechanism 2 is connected with the temporary storage mechanism 3 for stacking bale.

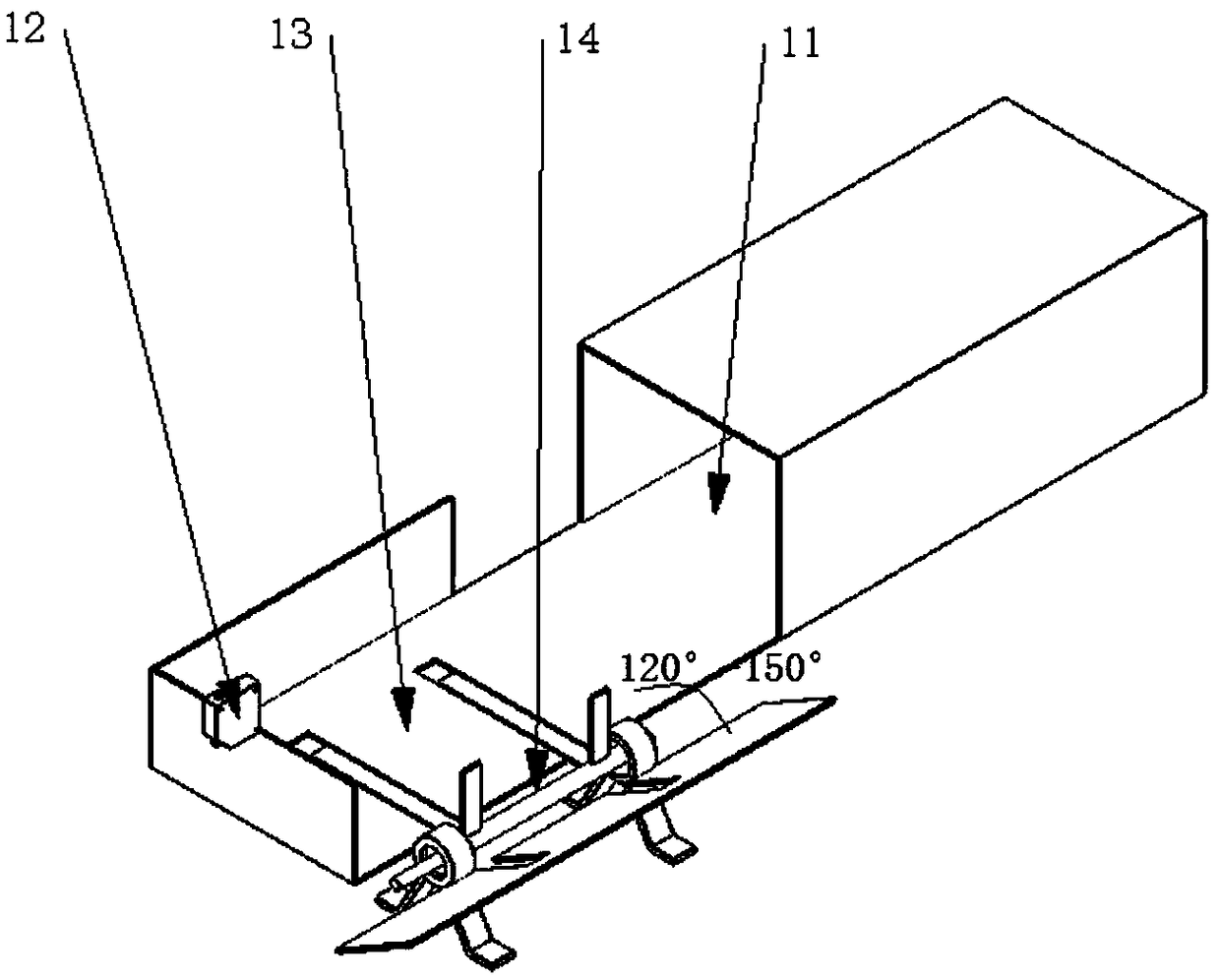

[0049] Such as figure 2 As shown, the bale conveying mechanism 1 includes a grass outlet 11, a photoelectric sensor 12, a bale conveying plate 13, and a bale turning device 14. When the photoelectric sensor 12 detects that the grass outlet 11 is sent The bale that comes sends a signal to the hydraulic motor immediately, and the hydraulic motor drives the bale overturning device 14.

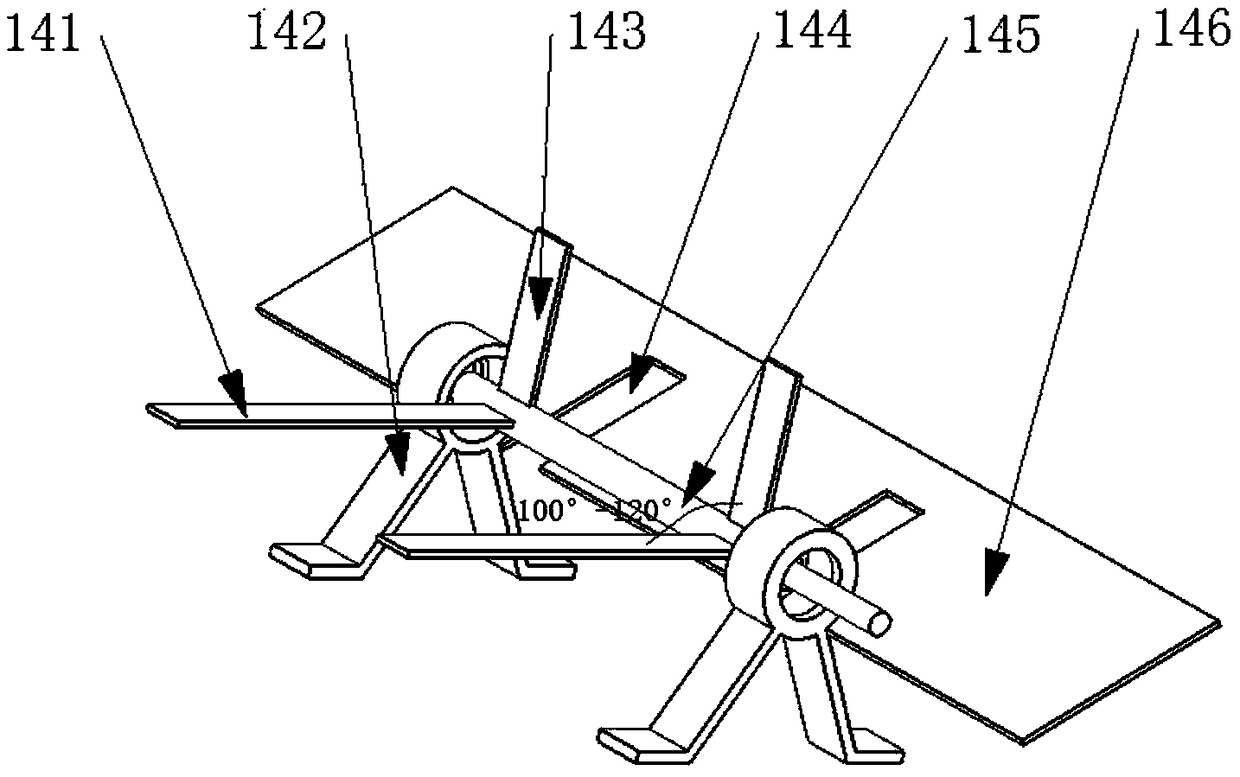

[0050] Such as image 3As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com