Special crevice cleaning brush for woven mat

A technology for cleaning brushes and gaps, applied in the field of bedding, can solve the problems that bacteria and mites are difficult to clean, and the gaps of mats are easy to fall into dust, etc., to achieve smooth rotation, reduce rotation resistance, and prevent movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

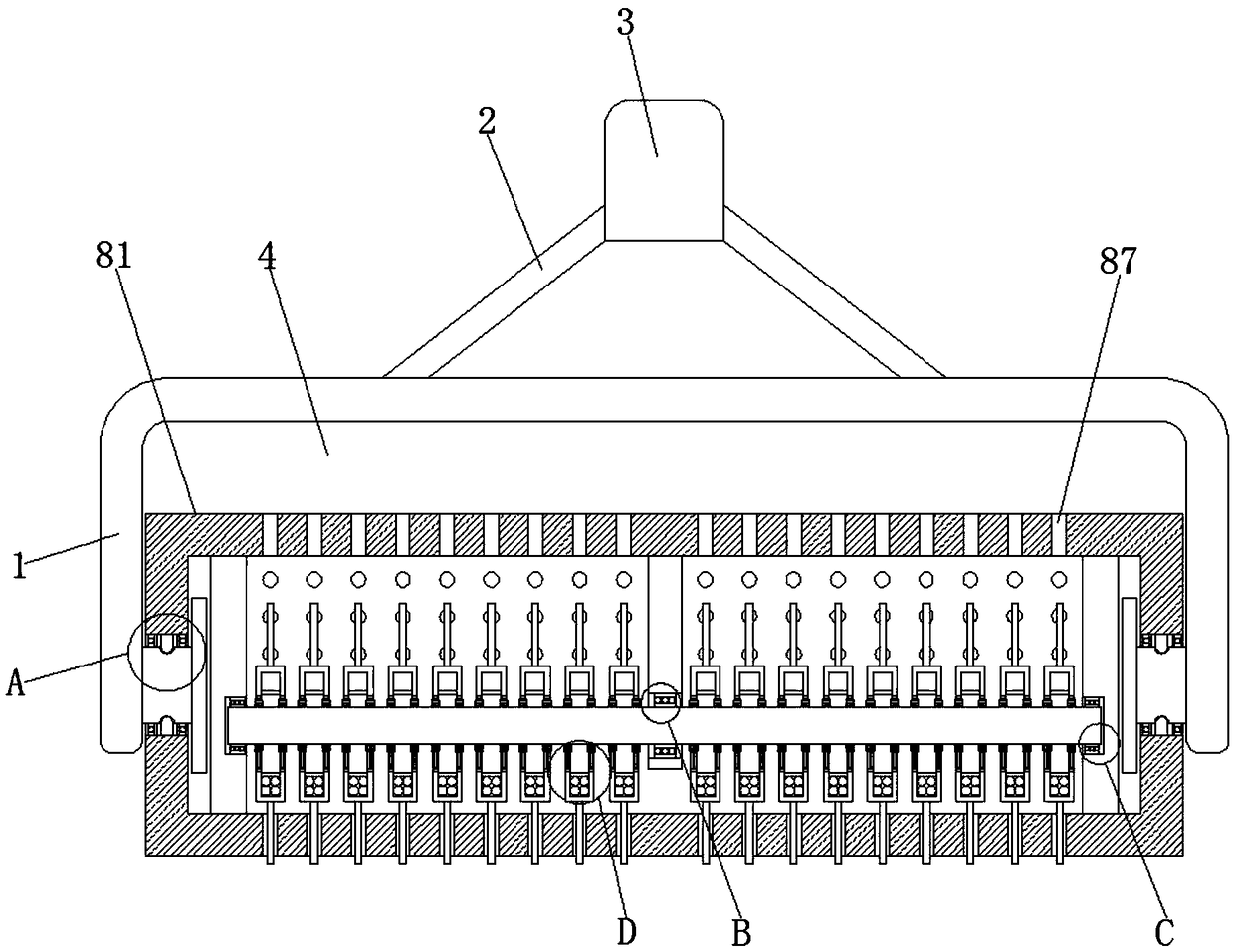

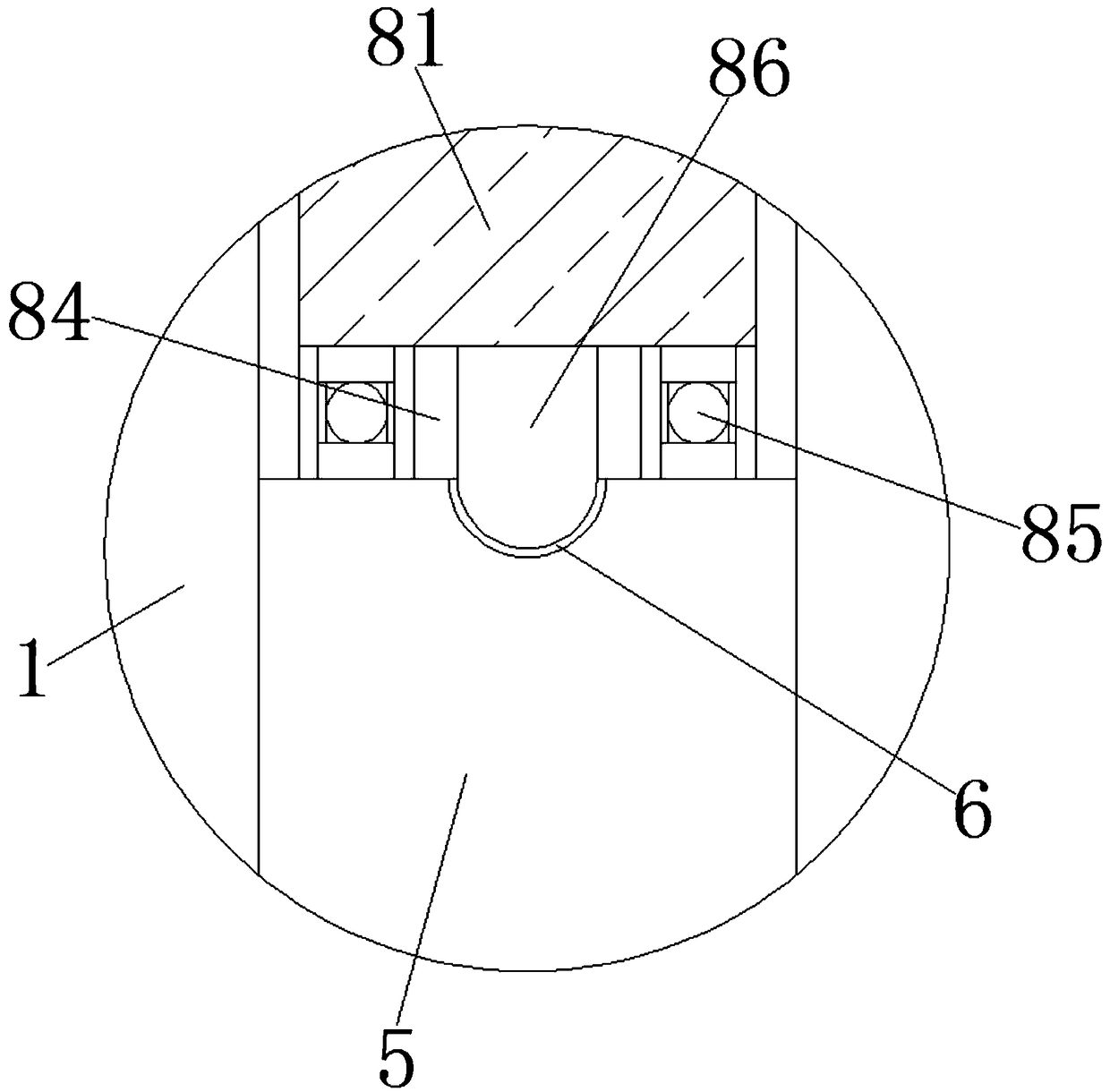

[0032] Such as Figure 1-5 As shown, a special gap cleaning brush for weaving summer mats includes a support frame 1, the two sides of the top of the support frame 1 are symmetrically fixedly connected with connecting rods 2, a handle 3 is arranged between the connecting rods 2 on both sides, and the surface of the handle 3 is provided with Anti-slip pattern, easy to hold, the center of the bottom of the support frame 1 is provided with a groove 4, the bottom of both sides of the inner wall of the groove 4 is symmetrically fixedly connected with the support column 5, and the middle part of the top and bottom of the support column 5 is symmetrically provided with a card slot 6, One end of the support column 5 away from the inner wall of the groove 4 is fixedly connected with a clamping plate 7 , and a cleaning mechanism 8 is provided at the bottom of the inner cavity of the groove 4 .

Embodiment 2

[0034] On the basis of Embodiment 1, the cleaning mechanism 8 includes a rotating roller 81, a supporting mechanism 82 and a lifting mechanism 83. The center of the rotating roller 81 on both sides is symmetrically provided with a limiting groove 84, and the two sides of the limiting groove 84 inner cavity are symmetrically provided with The first bearing 85, the middle part of the top and bottom of the inner wall of the limit groove 84 is symmetrically fixedly connected with a clamp post 86, the front, back, top and bottom of the rotating roller 81 are provided with through holes 87, and the bottom of the inner cavity of the rotating roller 81 is provided with Rotate shaft 88 .

Embodiment 3

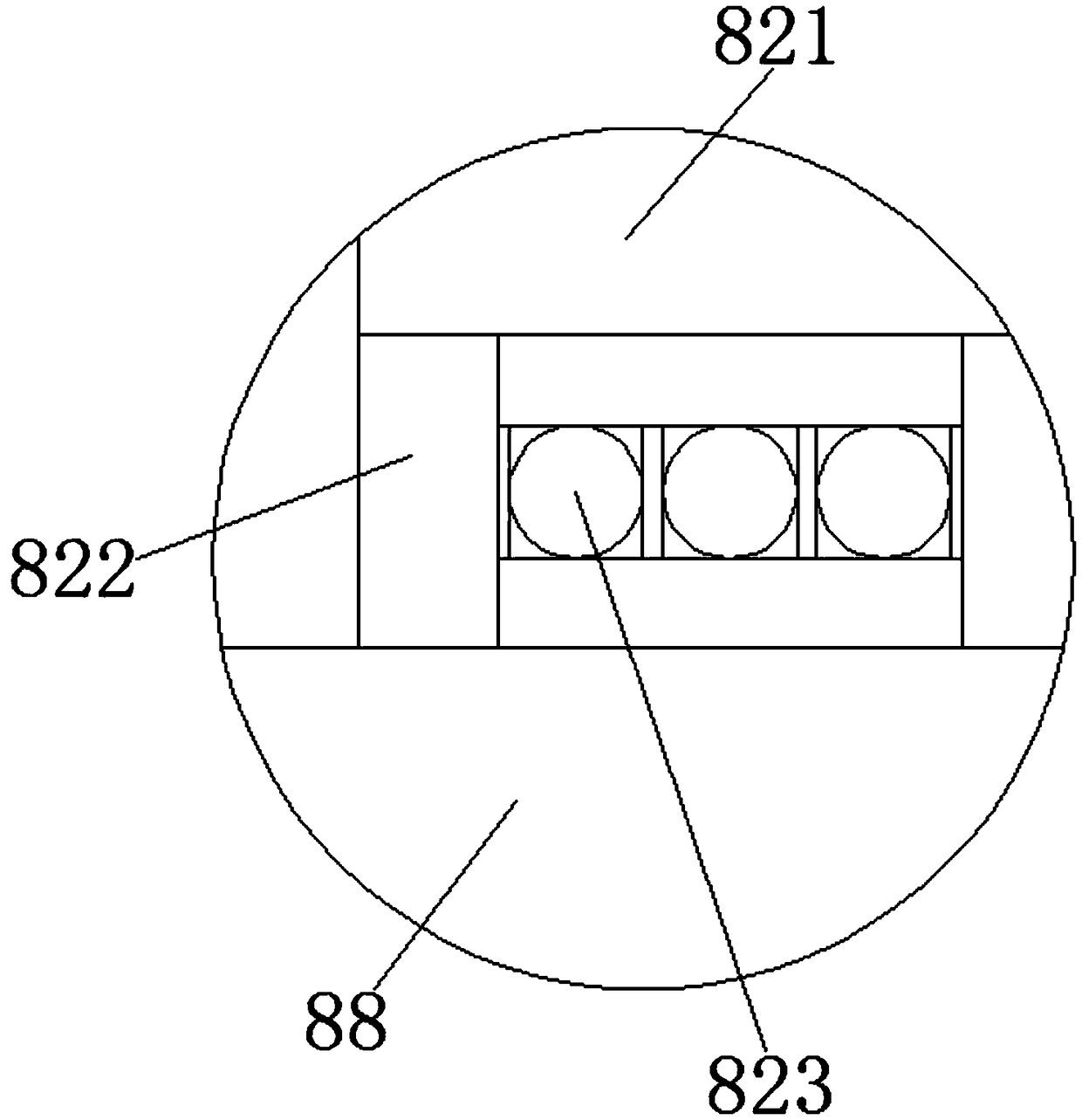

[0036] On the basis of Embodiment 1-2, the support mechanism 82 includes a support sleeve plate 821, a first rotation groove 822 is opened in the middle of the bottom of the support sleeve plate 821, and a second bearing 823 is provided in the inner cavity of the first rotation groove 822 to support Both sides of the sleeve plate 821 are symmetrically provided with support plates 824 , and the bottom of the opposite side of the support plate 824 is symmetrically formed with a second rotating groove 825 , and a third bearing 826 is disposed in the inner cavity of the second rotating groove 825 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com